Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

A manufacturing method and technology of cold-bending forming, which is applied in the field of roll-type continuous cold-bending forming of Z-shaped steel sheet piles, can solve the problems of high energy consumption in hot-rolled forming, lack of cold-bending continuous forming processing technology, etc., and achieve high production efficiency , fast and flexible delivery, and convenient production organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the drawings and embodiments.

[0051] Such as Figure 1-6 Shown.

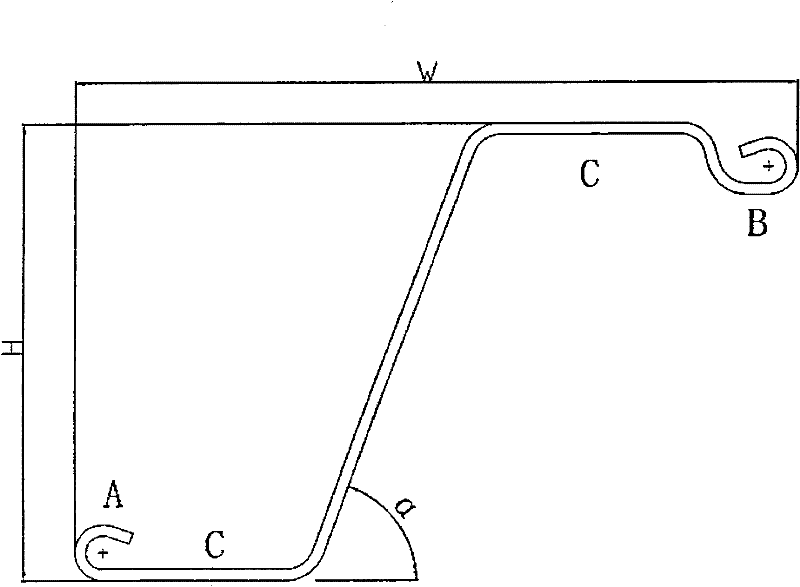

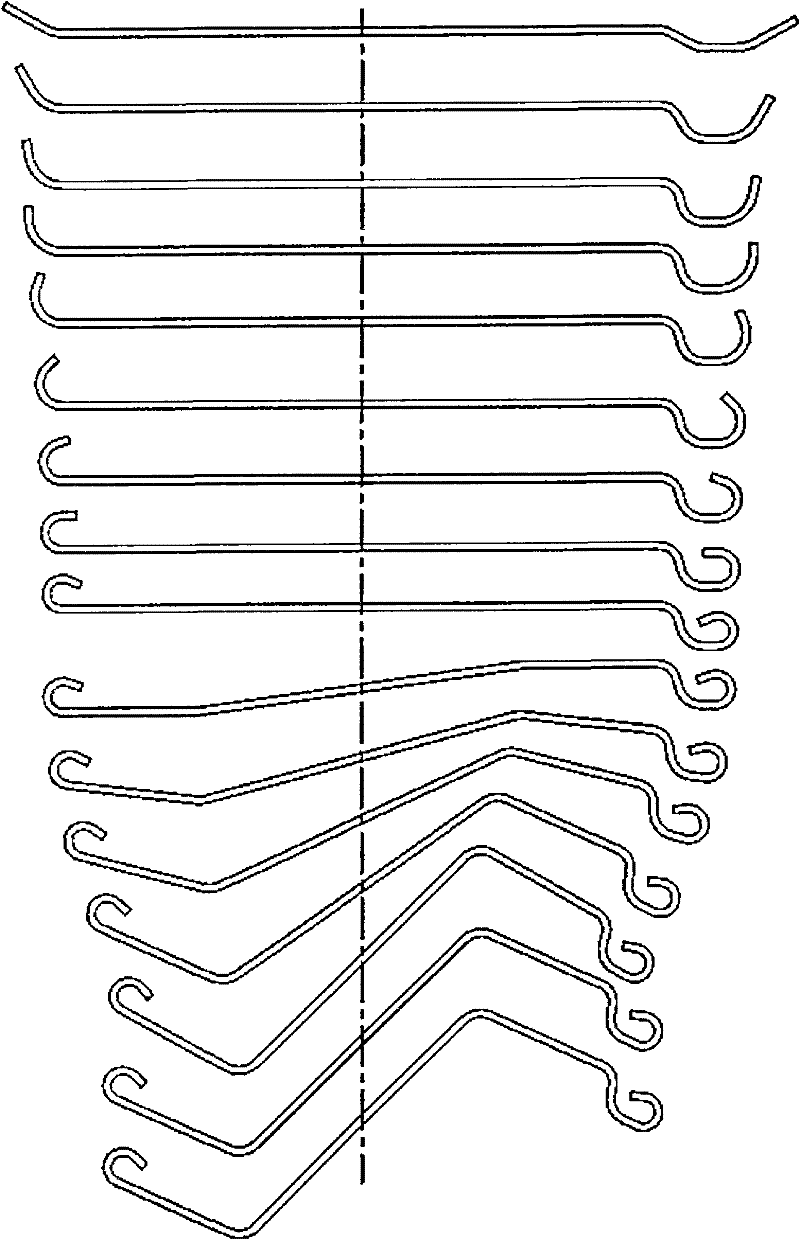

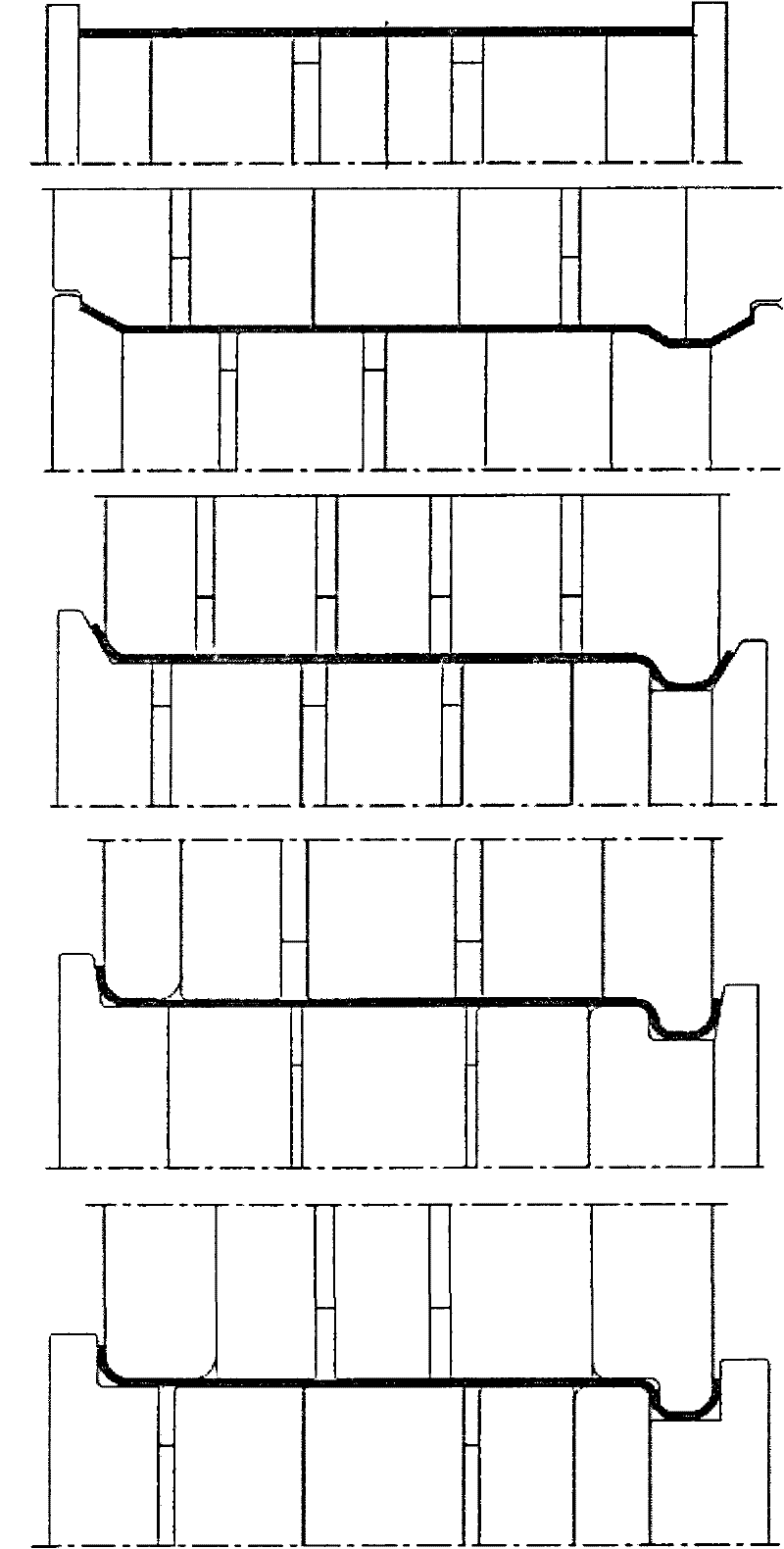

[0052] A Z-shaped steel sheet pile whose cross section is a Z-shaped structure. It has two locks A, B and two waists C, such as figure 1 As shown, it can be used Figure 3-6 The method shown and the continuous rolling die are continuously cold-formed. The continuous deformation process of the steel plate during the forming process is as figure 2 Shown. Refer to the roll forming mold for each process Figure 3-6 To design, as the key to continuous cold bending is the selection of deformation process and method, and deformation angle. The specific manufacturing process includes:

[0053] 1. Slitting strip steel

[0054] The hot-rolled coil is slit to the width of the process design on the slitting unit

[0055] 2. Uncoiling and leveling

[0056] The hot-rolled coil after slitting is opened on the decoiler on the cold bending forming unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com