Aluminum freezing box

A technology for freezer boxes and box covers, applied to boxes, impact-sensitive items, removable covers/covers, etc., which can solve problems such as easy pits, easy to tear damage, poor heat conduction effect, etc., to improve work efficiency , Easy to clean, easy to demould

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

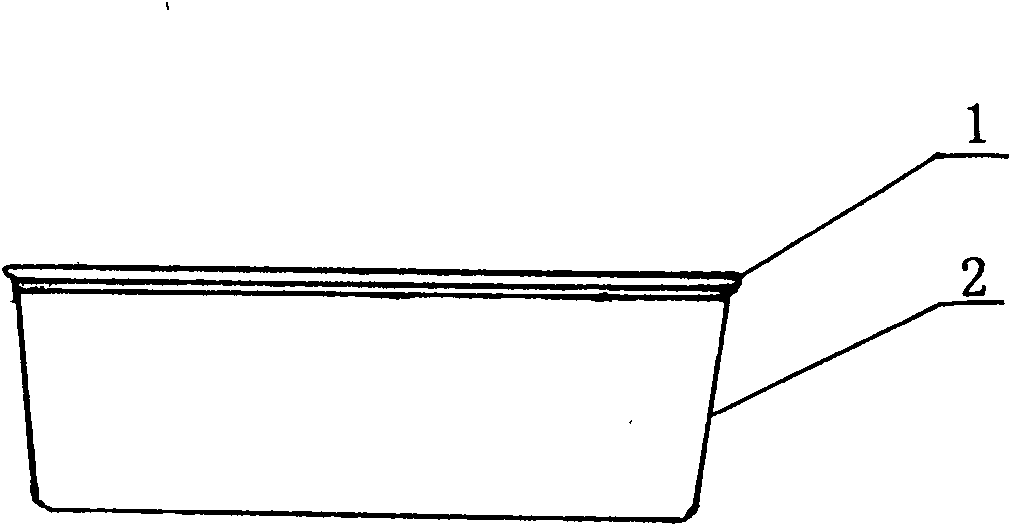

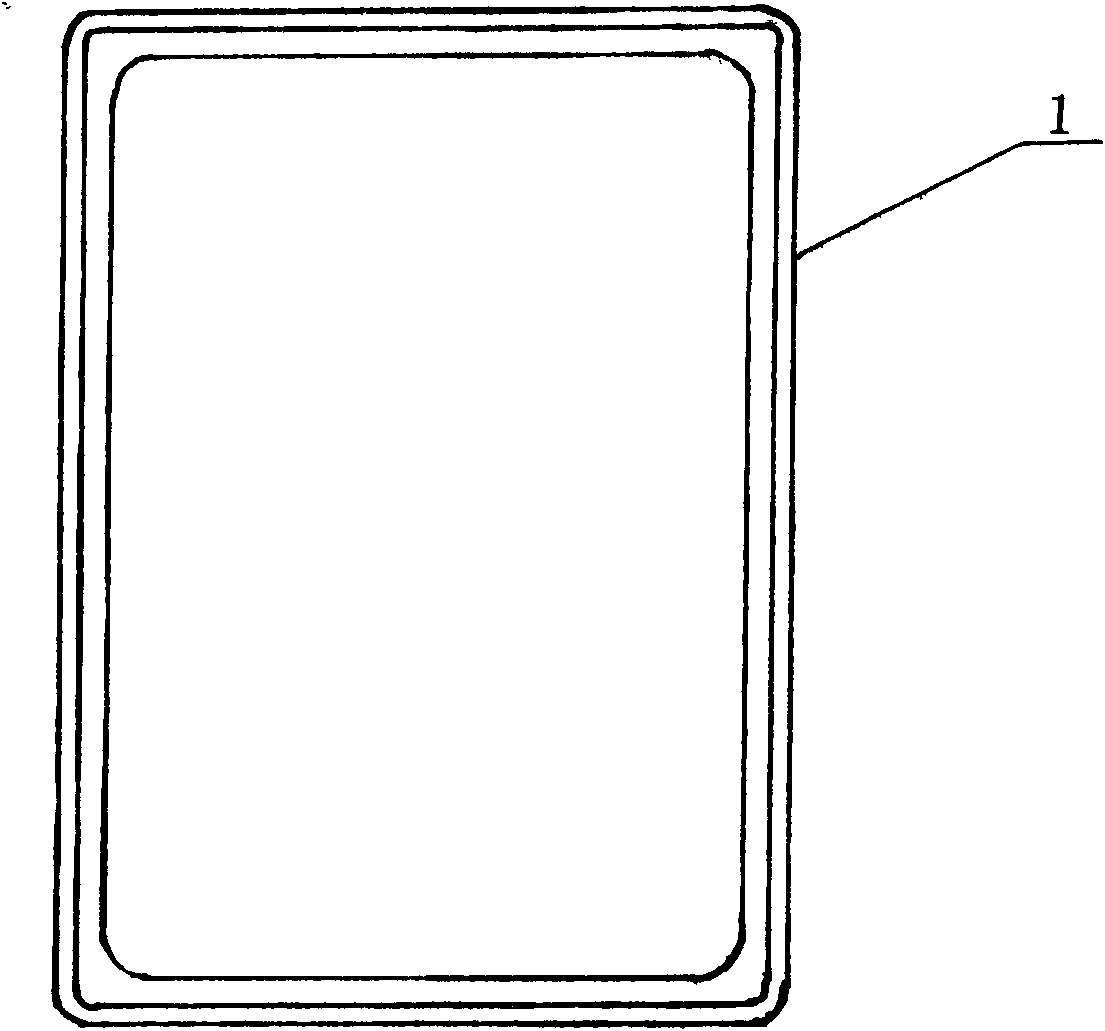

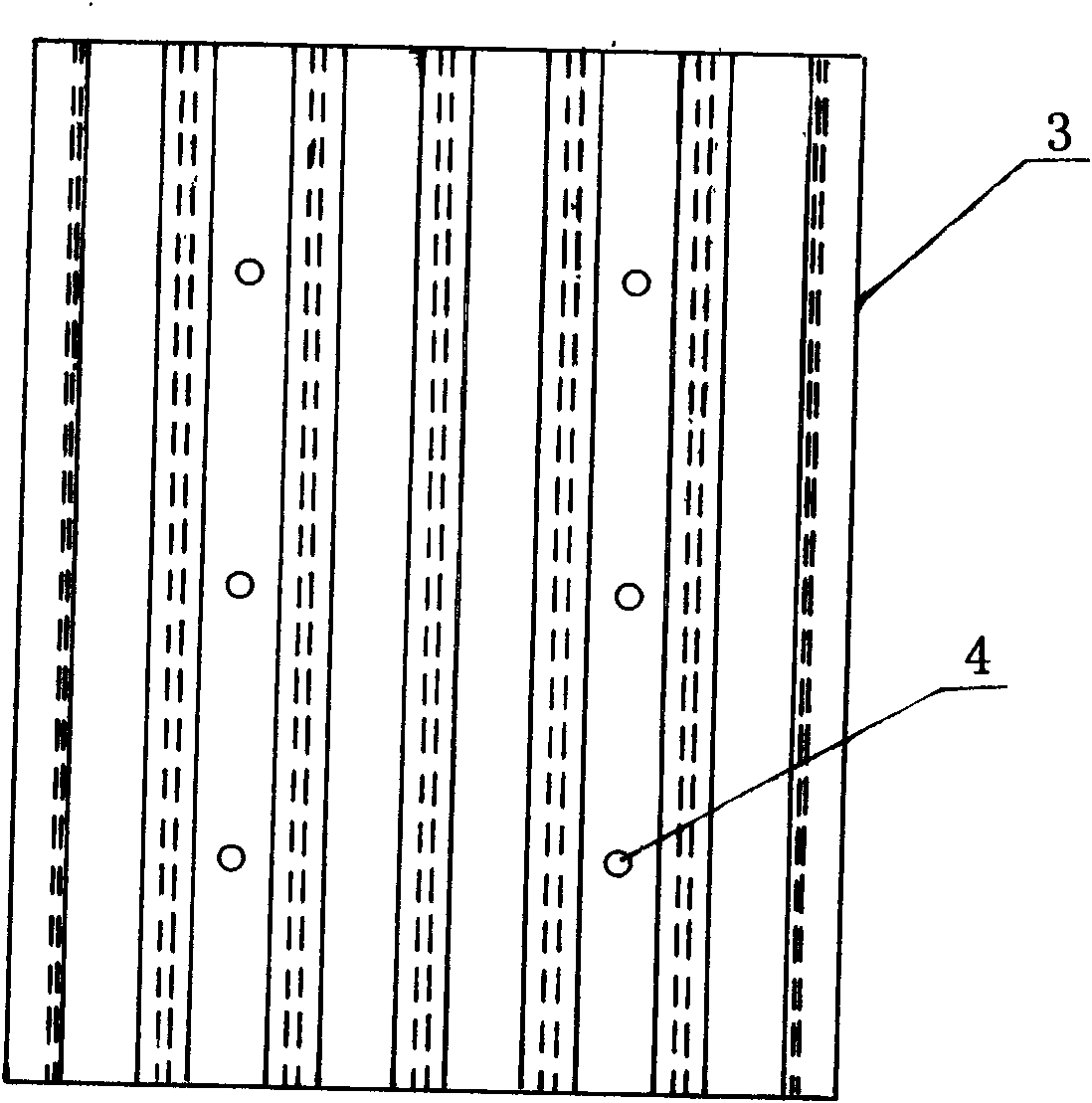

[0013] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is composed of a lower container 2 and a box cover 3, the lower container 2 is made of a 3.0 × 325 × 400mm aluminum plate whole plate into a mold to stretch, press with a 315t press, and cut the formed aluminum box with a 160t press. side. The box cover 3 is made of Ф350mm aluminum rods and put into the mold for extrusion, and a 2500t extruder is used. Degrease and oxidize the surfaces of the lower container 2 and the box cover 3 so that an oxide film is attached to the surfaces. It is not easy to be oxidized during the use of the freezer. A 10mm protrusion is provided at the peripheral edge 1 of the lower container 2 , and six openings 4 are provided on the surface of the box cover 3 . When it needs to be closed, it can be closed with the box cover 3; when it is not required to be closed, the lower container 2 can be used alone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com