High-intensity welding point geogrid

A geogrid and welding point technology, which is applied in infrastructure engineering, roads, excavation, etc., can solve the problems of low welding strength between ribs, affecting the service life of grids, and low shear resistance of joints. Achieve the effect of improving shear resistance, prolonging service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

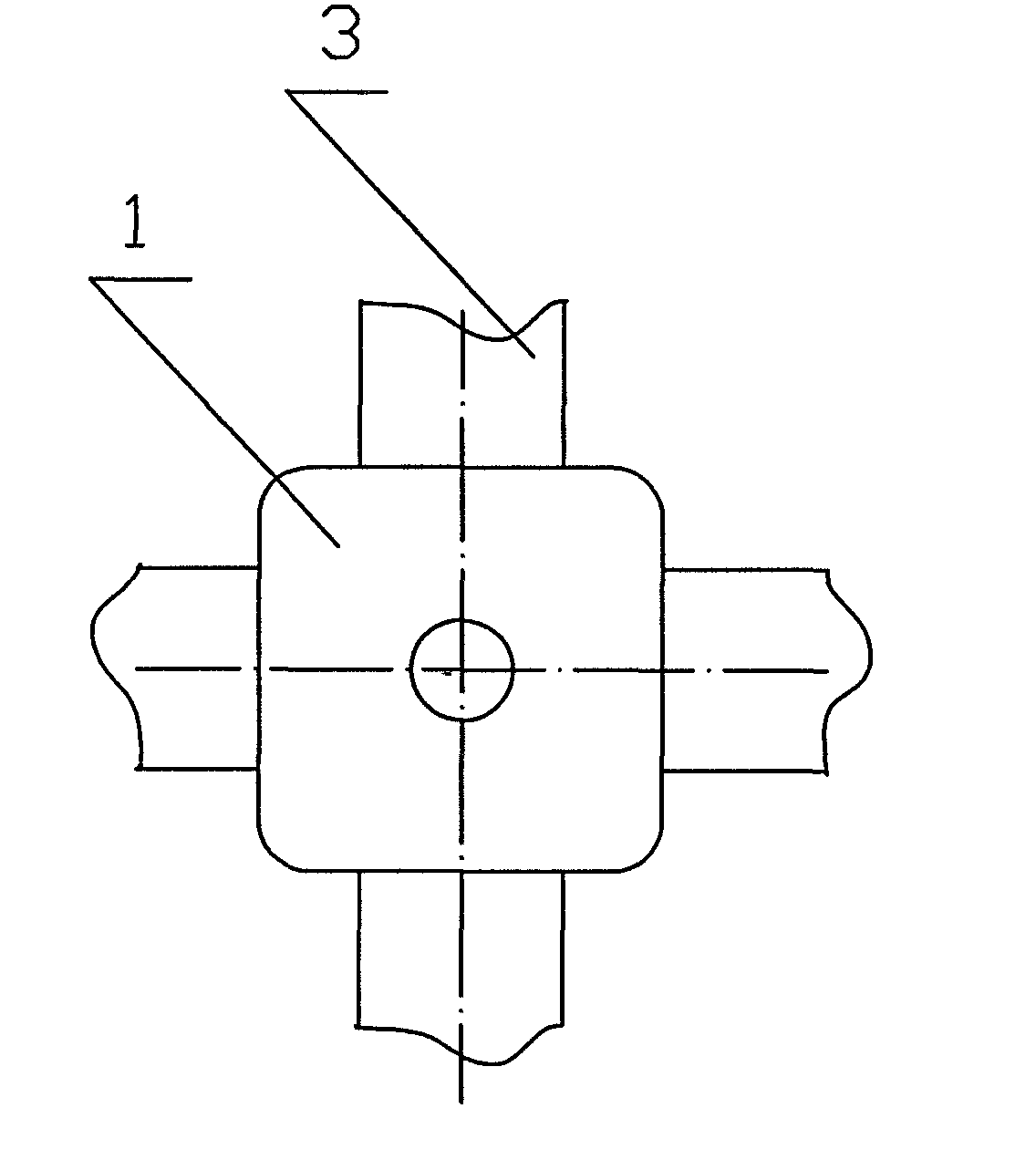

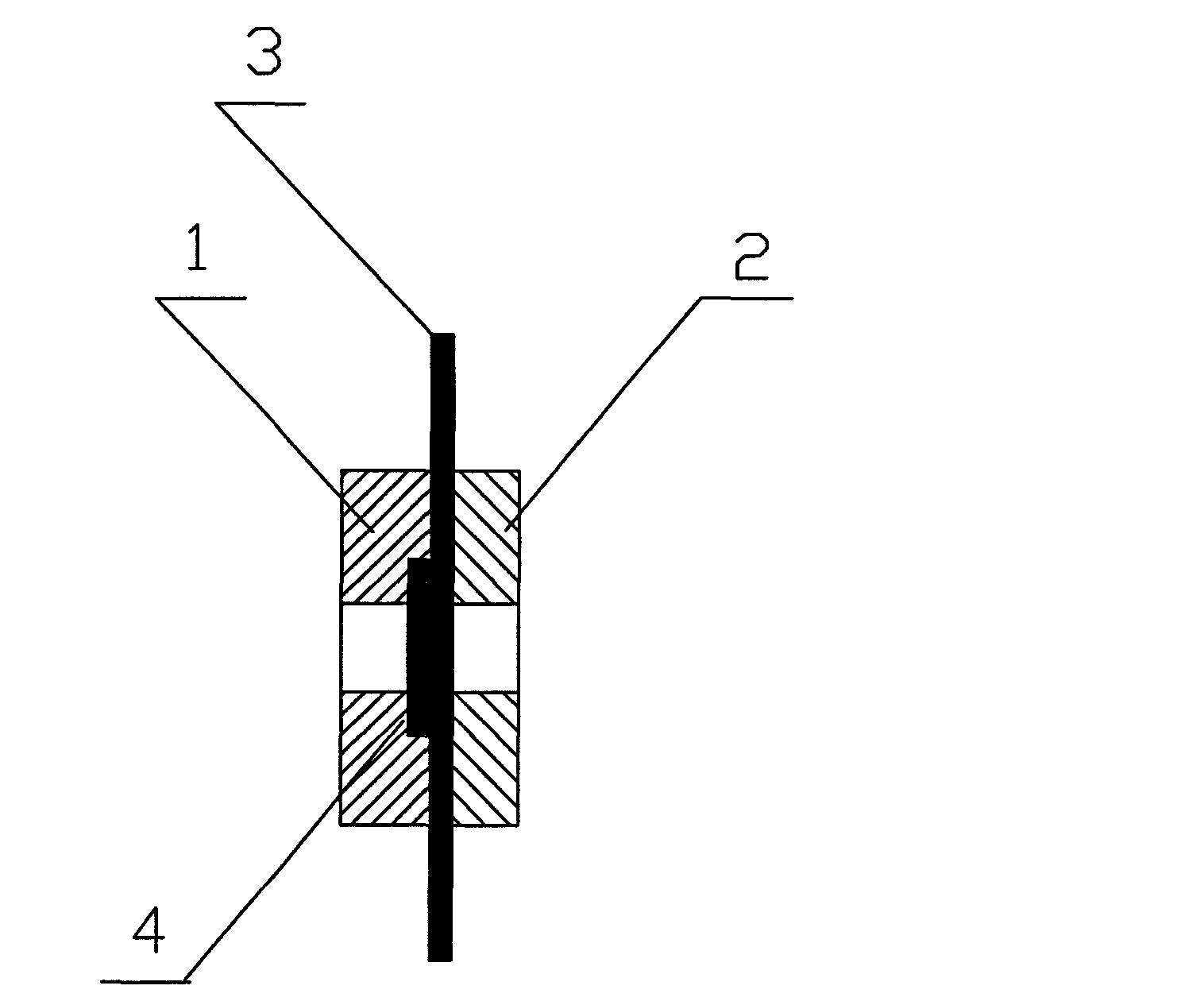

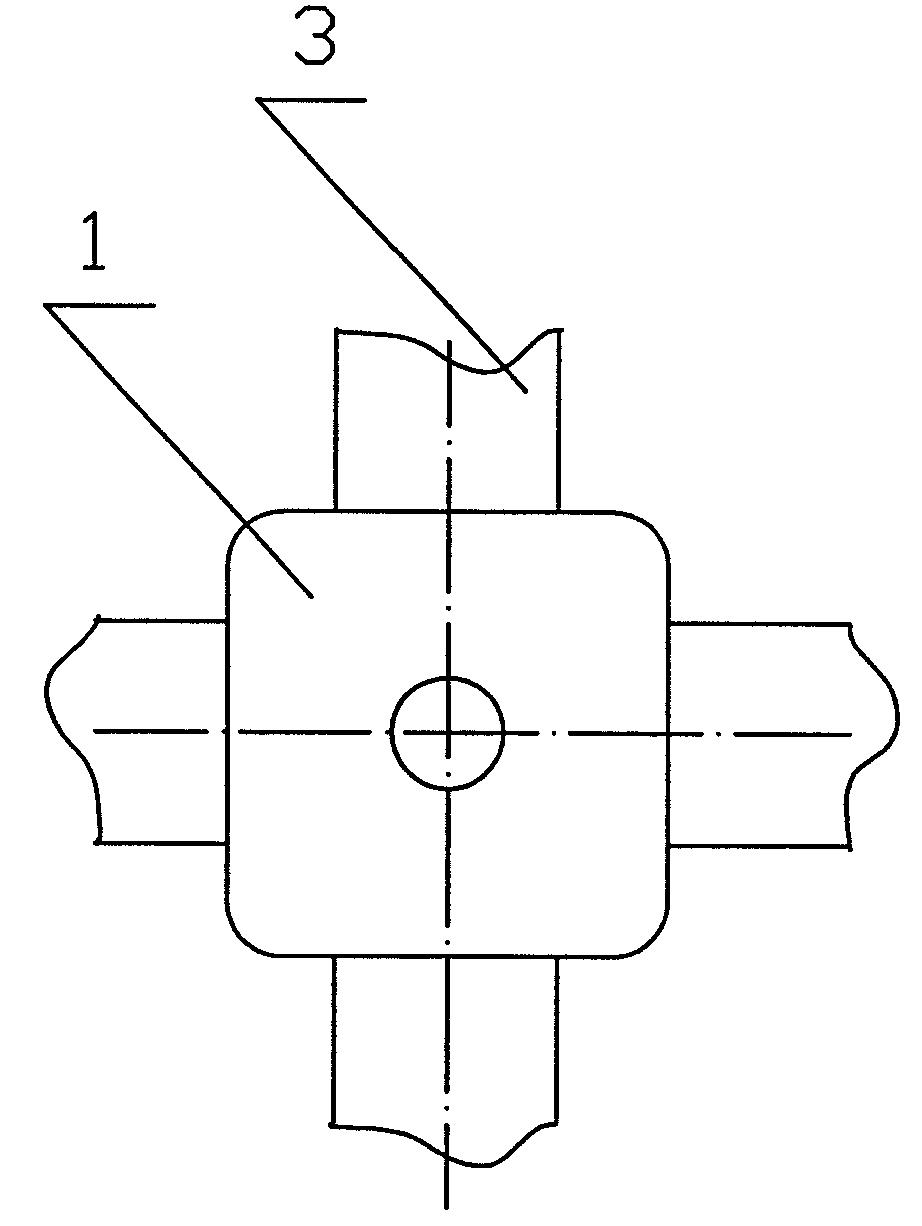

[0013] A high-strength welded point geogrid, including ribs 3, is characterized in that the adjacent ribs 3 are placed between the upper connecting piece 1 and the lower connecting piece 2, through the upper connecting piece 1 and the lower connecting piece The connecting block composed of 2 is welded as a whole by ultrasonic welding.

[0014] A groove 4 is provided on the joint surface of the upper connecting piece 1 and / or the lower connecting piece 2 .

[0015] Grooves 4 corresponding to the size of the geogrid can be made on the joint surface of the two connecting sheets according to the width and thickness of the geogrid. When the geogrid is manufactured, the upper connecting piece 1 and the lower connecting piece 2 are installed at the joint between the ribs 3 and the ribs 3, and they are welded firmly by ultrasonic waves.

[0016] The grid made of the connecting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com