Method for spraying wheel-sticking preventing liquid on asphalt pavement compacting equipment

A technology of asphalt pavement and anti-sticking wheels, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of insufficient compaction of asphalt rolling temperature, high labor intensity of workers, and potential safety hazards, so as to save water or spray The effect of reducing oil volume, reducing labor intensity of workers, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

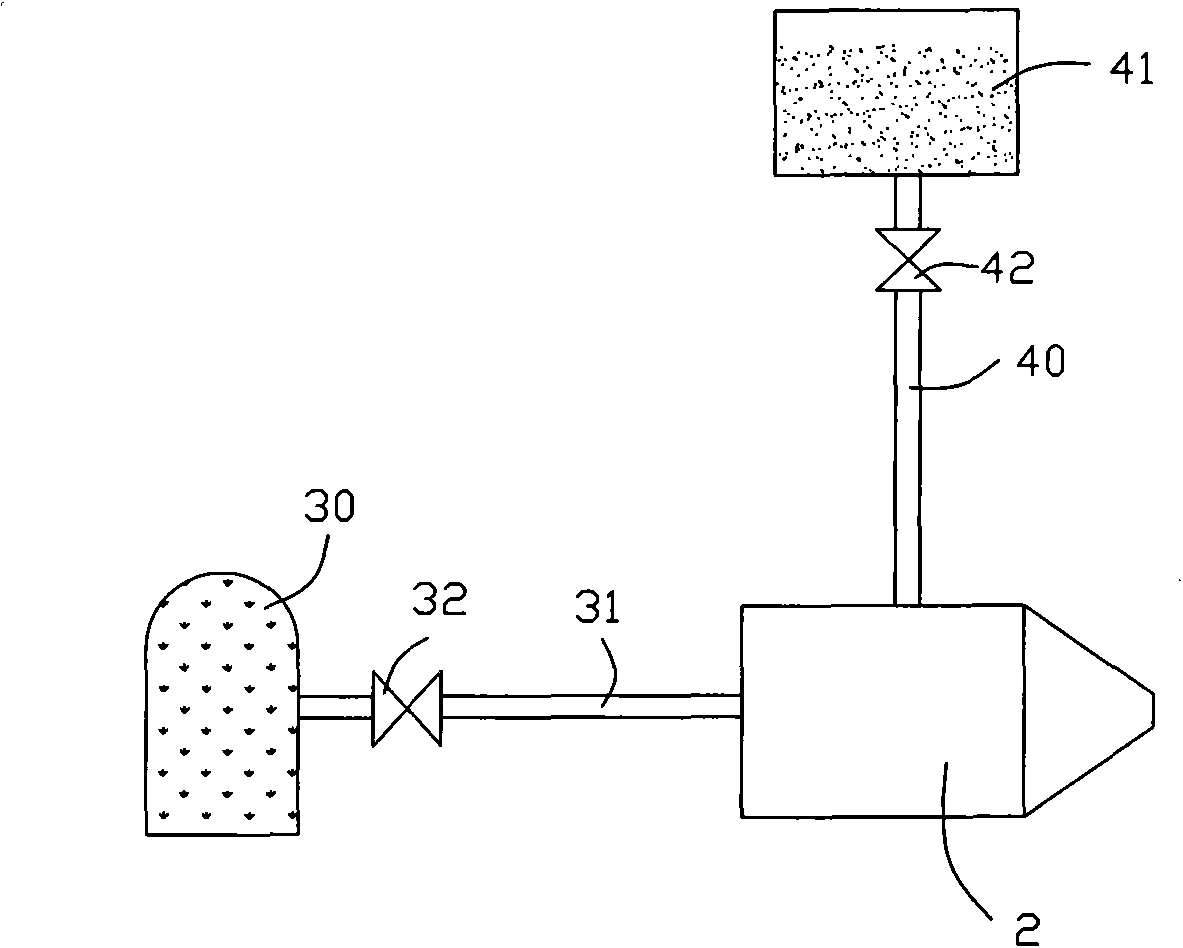

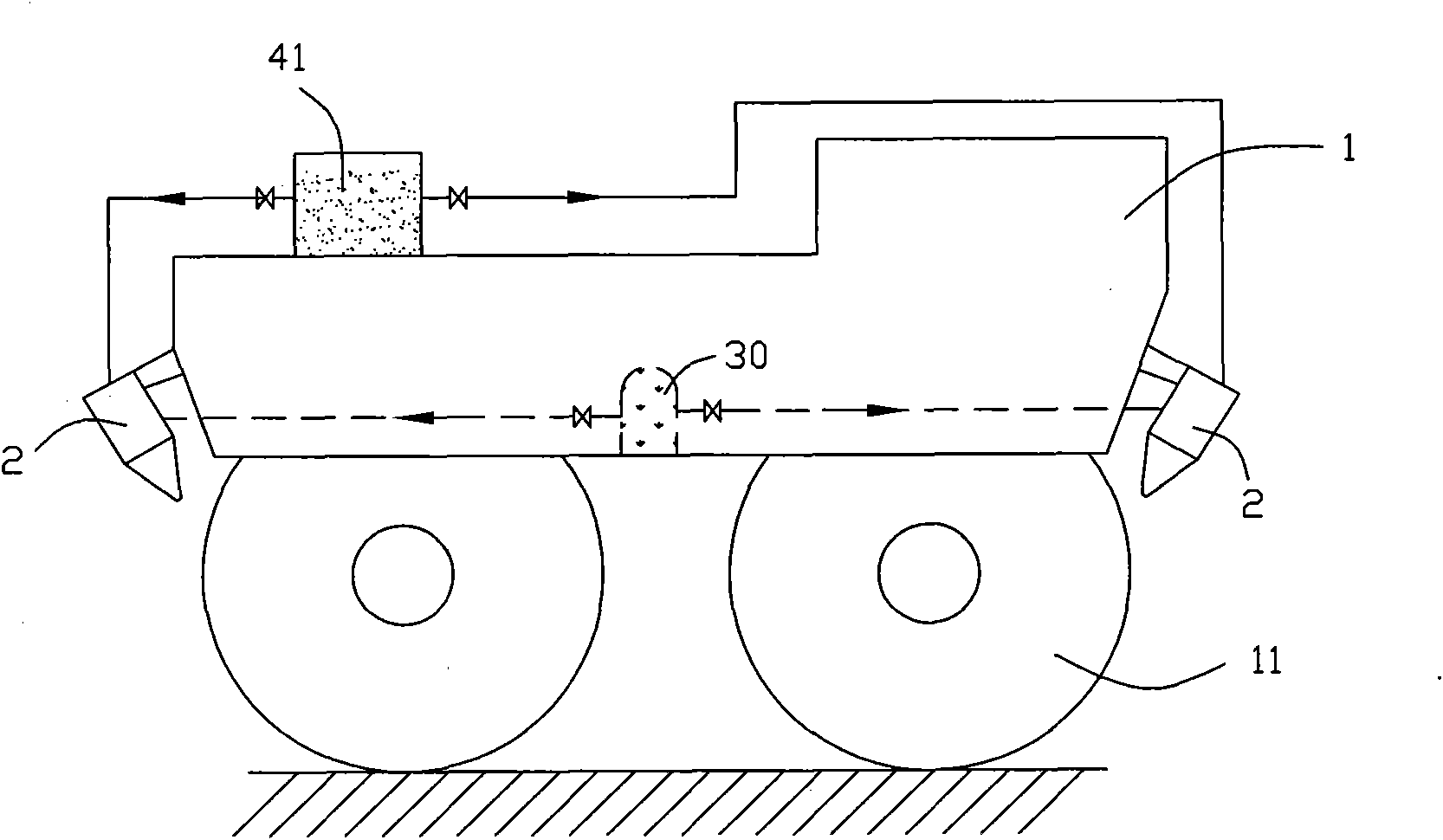

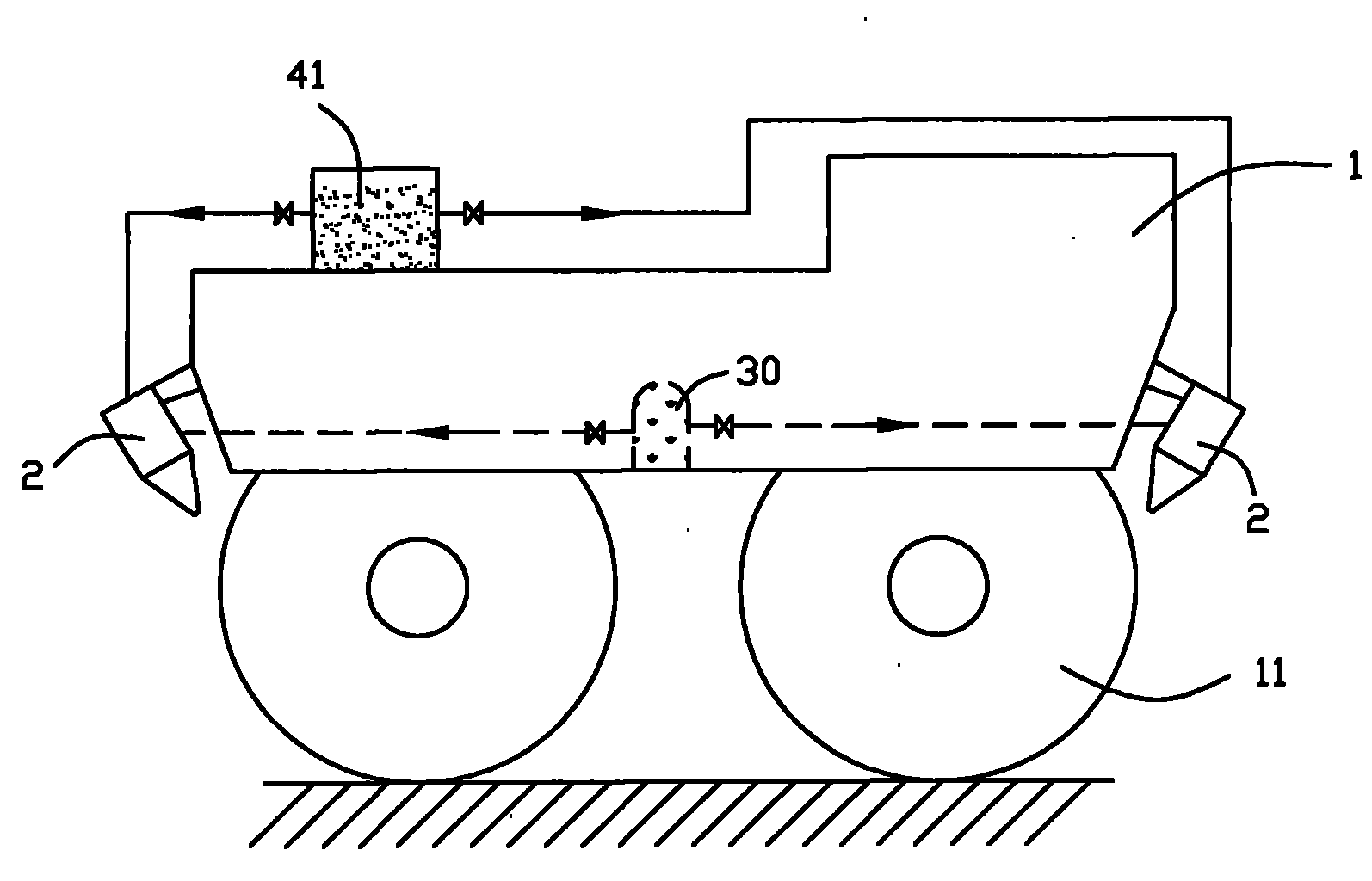

[0014] see Figure 1 to Figure 2 , shows a preferred mode of the method for spraying the anti-sticking wheel liquid of the asphalt pavement compacting equipment of the present invention, which includes a road roller 1 for compacting asphalt pavement, and the method is to spray the liquid flowing into the spray head 2 by means of an air spray device On the roller 11, the air pressure of the air injection device is provided by the air brake system of the roller. The air brake braking system is an existing technology, which includes an air compressor, a brake valve, an air storage tank, and a brake operating device. During the braking process, the engine drives the air compressor to rotate, and the compressed air generated is stored in the air storage tank. Inside, compressed air enters each brake operating device through the brake valve to achieve braking. The present invention utilizes the compressed air in the air storage tank in the existing air brake system, and guides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com