Pile-column integrated ground photovoltaic bracket

A photovoltaic bracket and integrated technology, which is applied to the supporting structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of sand and dust pollution around the construction site, high labor costs, and long construction periods, so as to save labor costs, The effect of simplifying the adjustment process and shortening the connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

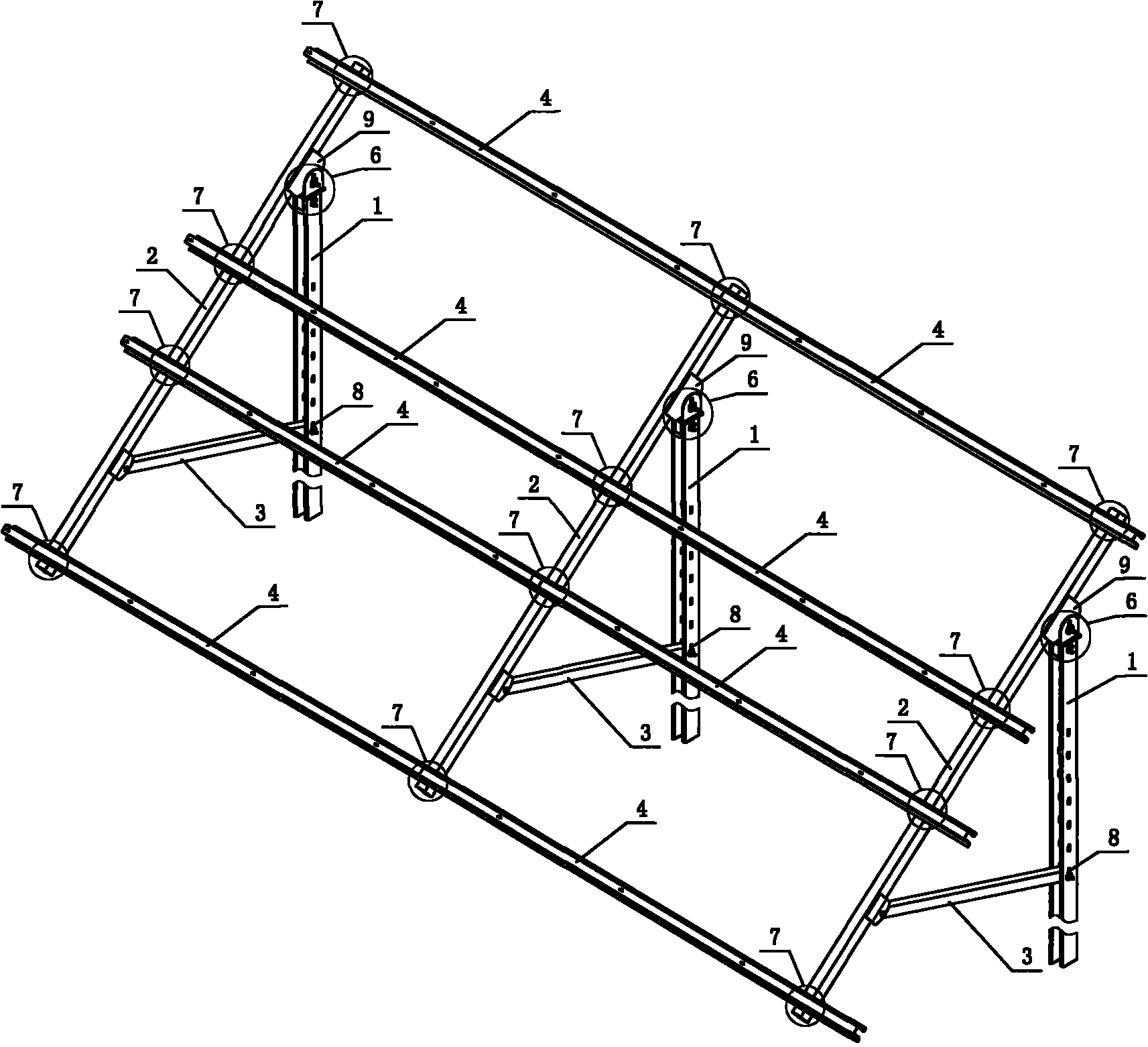

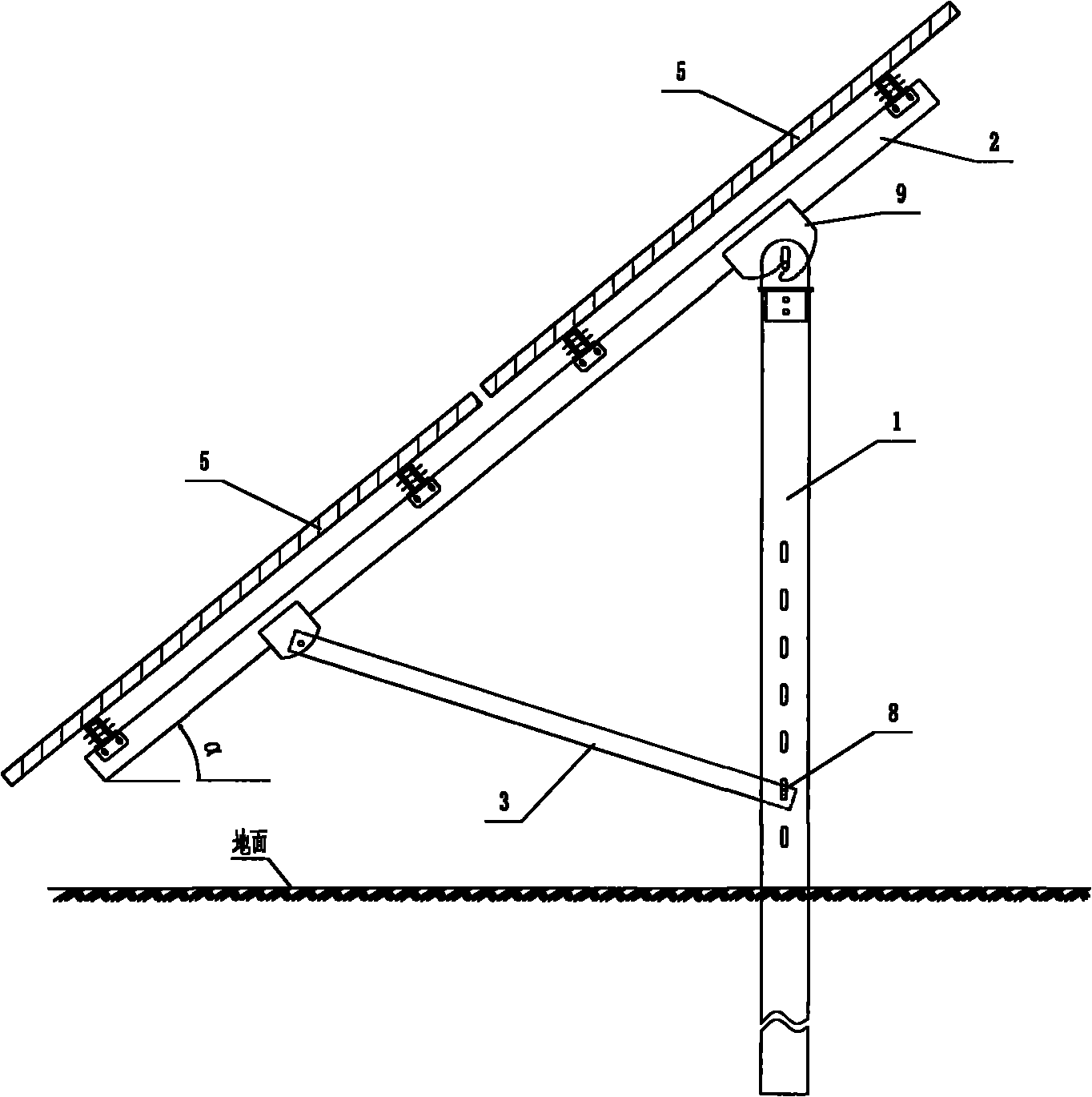

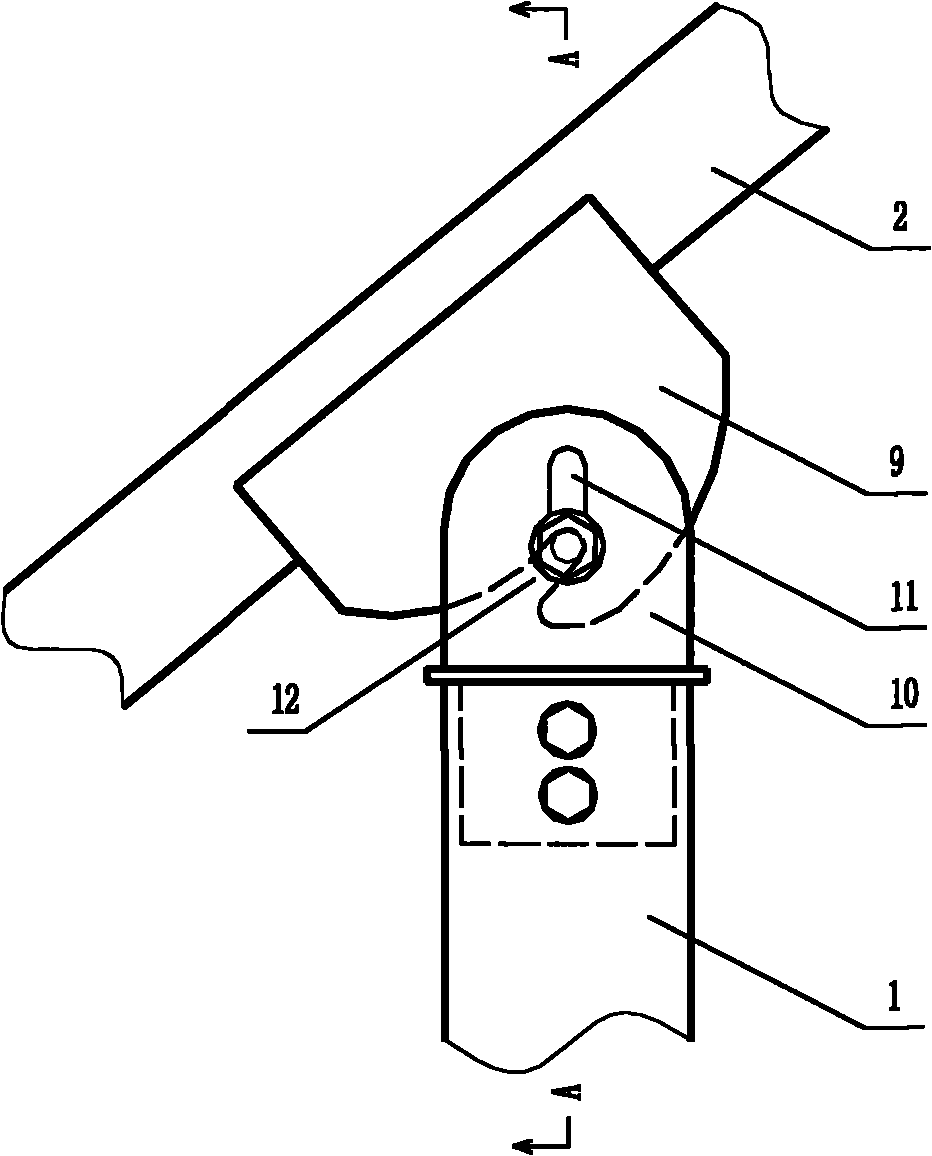

[0025] like figure 1 , figure 2 As shown, in this embodiment, the pile-integrated ground-adjustable photovoltaic support includes three beams 2 distributed at intervals, and the beams 2 are parallel to each other. The top surface of the beam 2 is fixedly coupled with four rails 4 at intervals along the length direction. Each beam 2 is provided with a number of track adjustment holes 14, and these track adjustment holes 14 are specifically located on the connection area between the beam 2 and each track 4; on the connection area between the beam 2 and each track 4, along the length of the beam 2 There are two track adjustment holes 14 in the direction; the beam 2 is fixedly connected with the corresponding track 4 at the track adjustment hole 14, and each track 4 is parallel to each other; the three beams 2 are connected with a support body on the back, and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com