Humidifying membrane module

A humidification membrane and module technology, applied in the field of humidification membrane modules, can solve the problems of increasing the weight of the membrane module, increasing the manufacturing cost, increasing the assembly process, etc., and achieves the effects of miniaturization, improved performance, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, according to Figure 1 to Figure 4 Preferred embodiments for carrying out the present invention will be described.

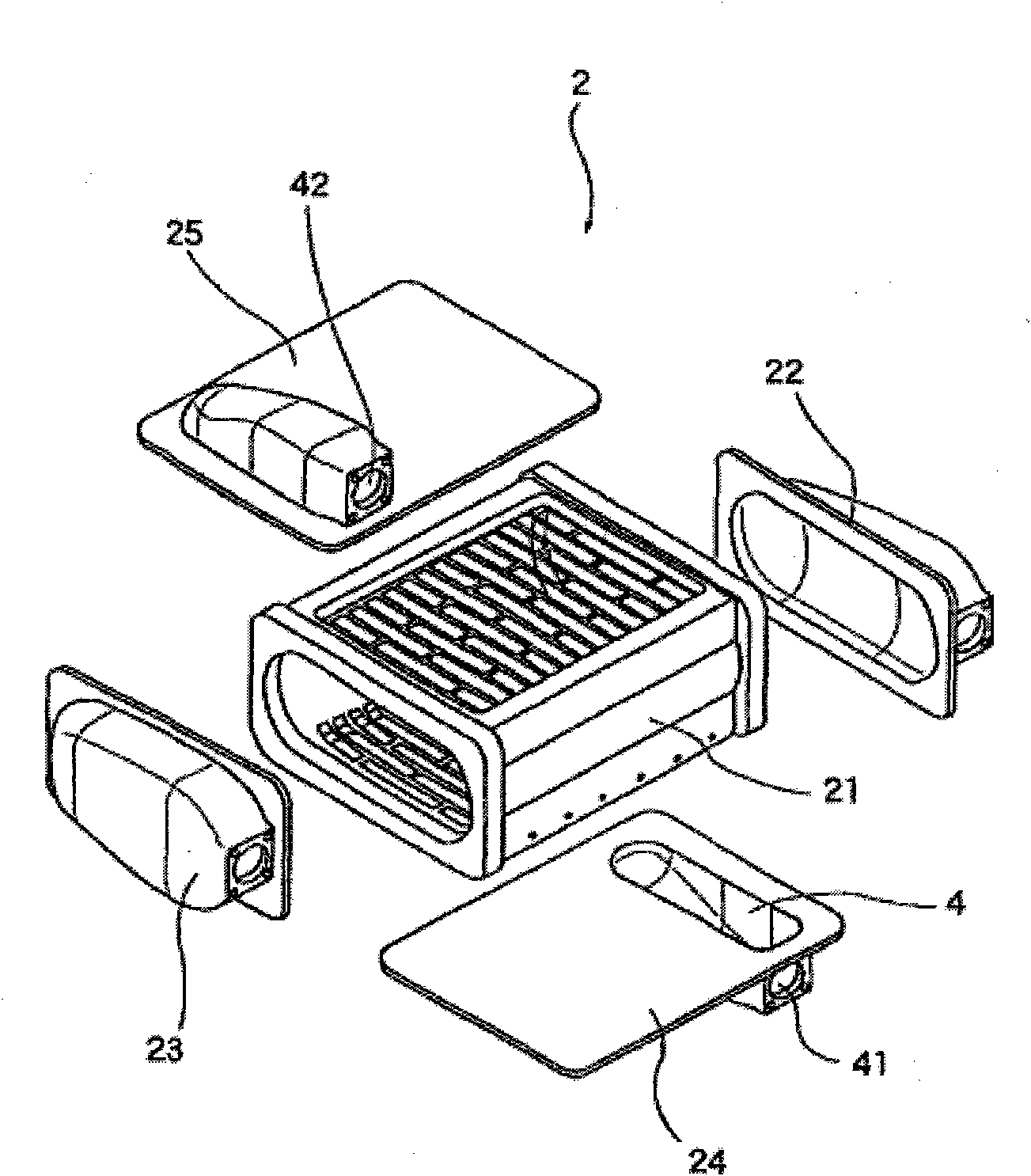

[0050] figure 1 It is a perspective view before assembly of the box used for the humidification membrane module of this invention.

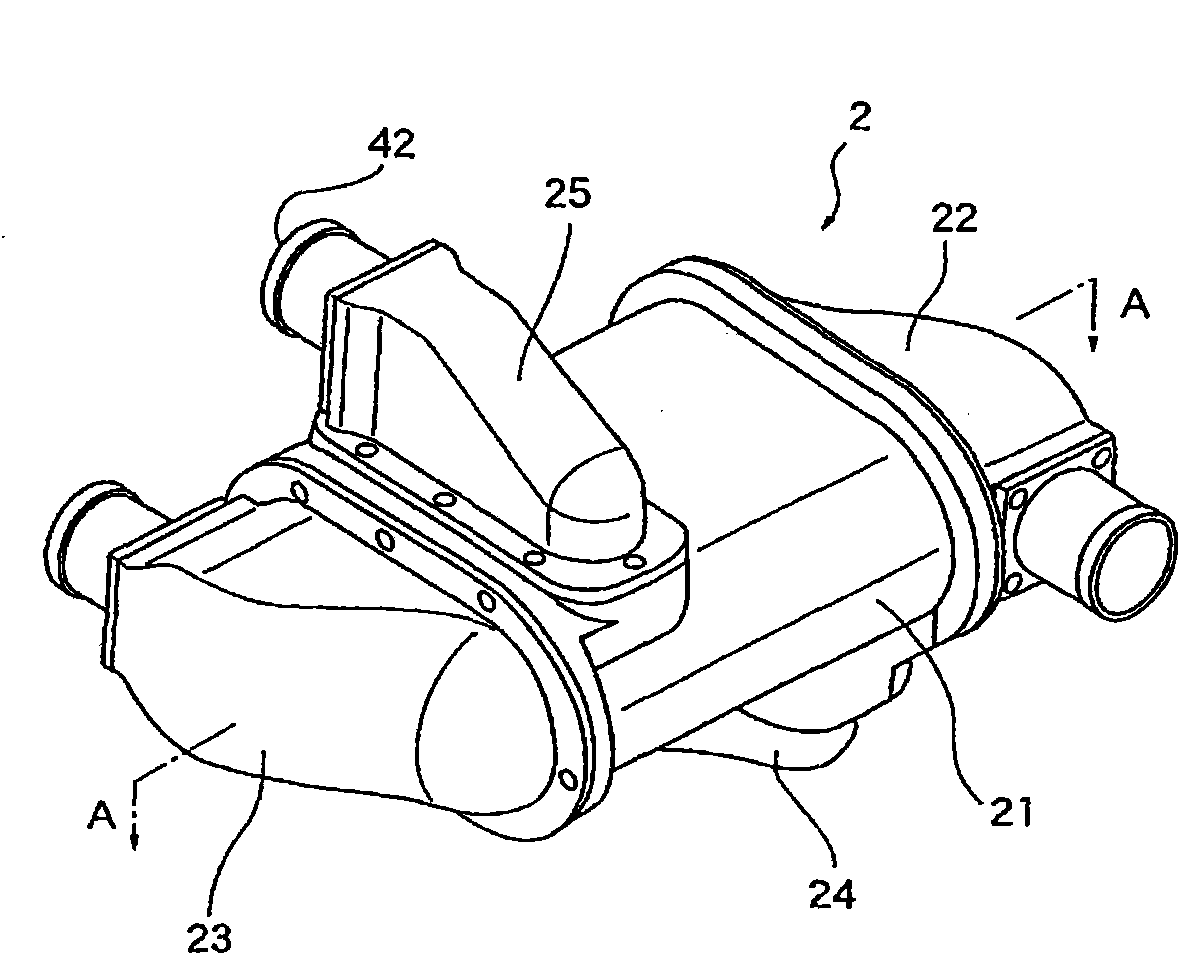

[0051] figure 2 It is an assembly view of the humidifying membrane module of the present invention.

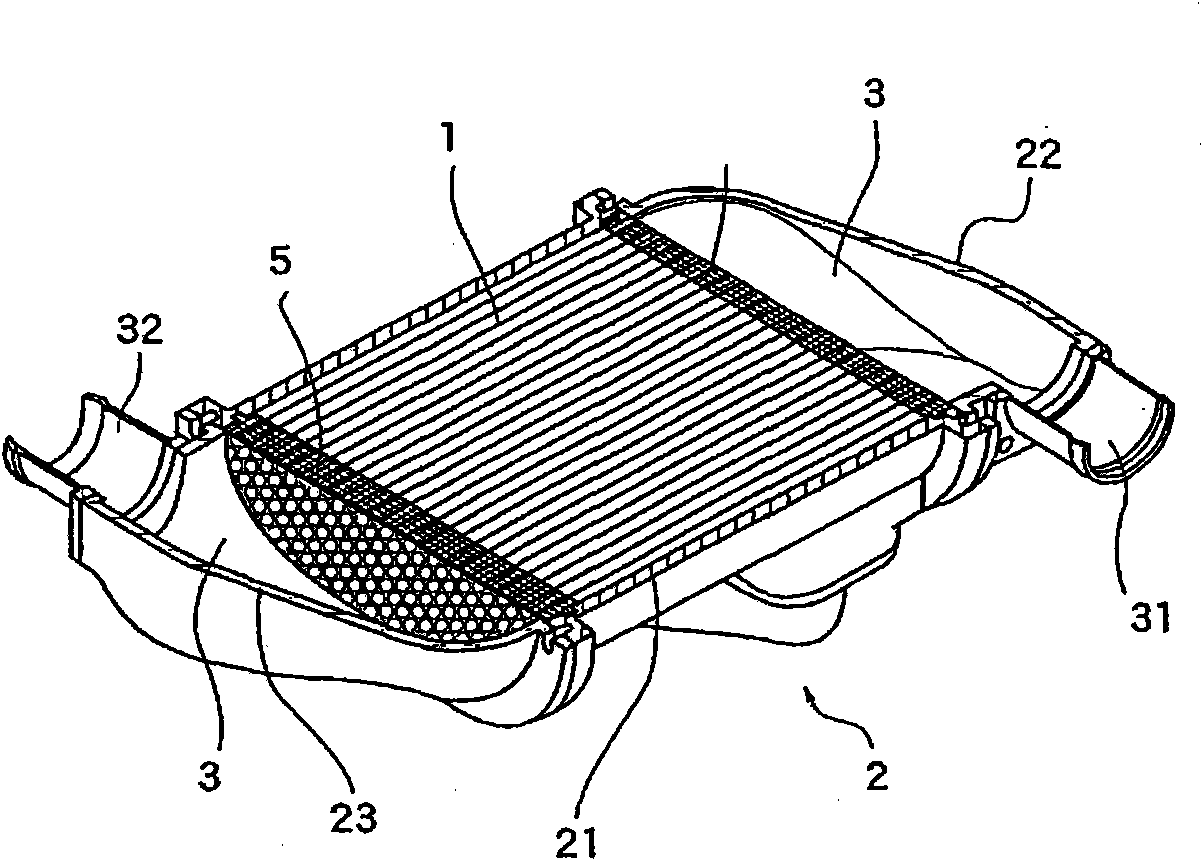

[0052] image 3 for figure 2 A-A cutaway view.

[0053] Figure 4 for image 3 Partial enlarged view of .

[0054] Humidification membrane assembly of the present invention, such as Figure 1 to Figure 4 As shown, it includes: a hollow fiber membrane bundle 1 formed by a plurality of hollow fiber membranes; a box 2 for accommodating the hollow fiber membrane bundle 1; a first flow path 3 passing through the hollow interior of the hollow fiber membrane; The second flow path 4 on the outer wall side of the and, if image 3 with Figure 4 As shown, at both ends of the hollow fiber membrane bundle 1 , the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com