Honeycombed body with a connection free area

A honeycomb, zone technology for catalyst supports, machines/engines, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

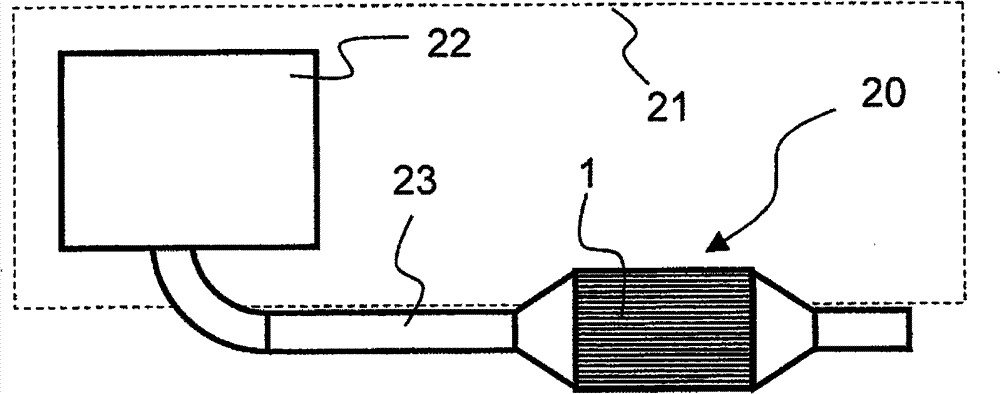

[0031] figure 1 The configuration of an on-board exhaust system of a motor vehicle 21 is schematically shown. The motor vehicle 21 has an engine 22 , for example a spark ignition engine or a compression ignition engine. The fuel combusted in the engine 22 is led as exhaust gas to the exhaust gas treatment unit 20 via a corresponding exhaust pipe 23 . In the exhaust gas treatment unit 20 , the harmful substances contained in the exhaust gas are at least partially converted and / or recirculated, so that in the end only relatively harmless exhaust gas components flow into the surroundings. Obviously, in this exhaust system, the number, type and / or location of such exhaust treatment units 20 can be changed according to various aspects (factors). A possible embodiment of the honeycomb body 1 shown in the figure is located in the exhaust pipe 23 .

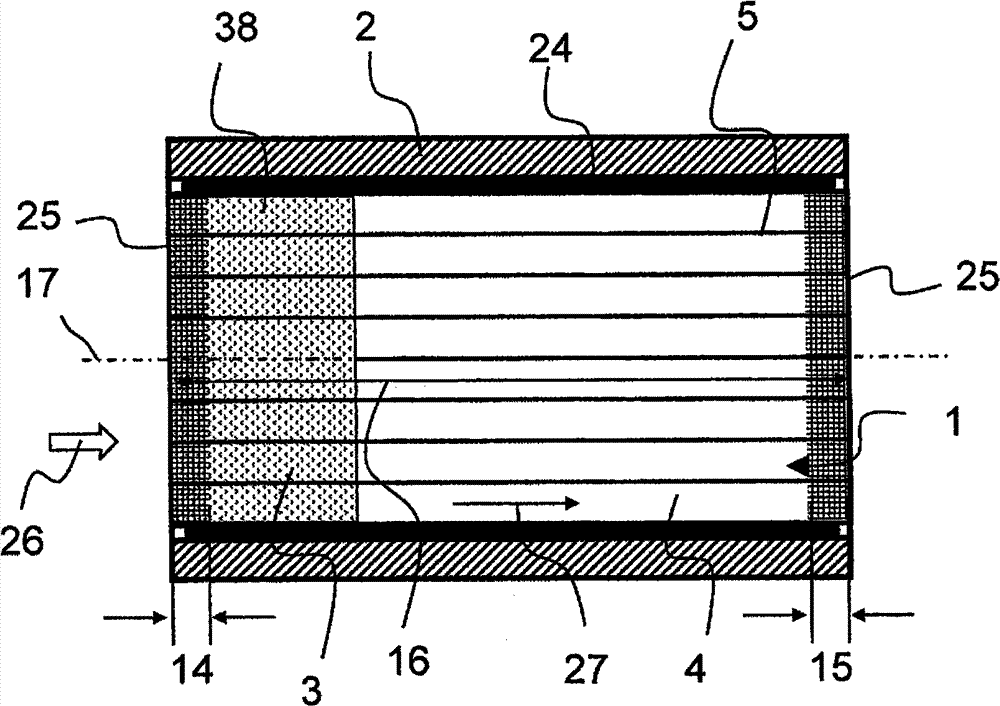

[0032] For example from figure 2 The structure of the honeycomb body 1 can be seen. figure 2 is a longitudinal section of the (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com