Method for fixing seabed pipeline and preventing buckle propagation

A subsea pipeline and buckling prevention technology, which is applied in the directions of pipeline laying and maintenance, pipeline support, pipe/pipe joint/pipe fittings, etc., can solve problems such as large vertical uplift or lateral displacement, achieve convenient operation, reduce manufacturing costs, avoid The effect of structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

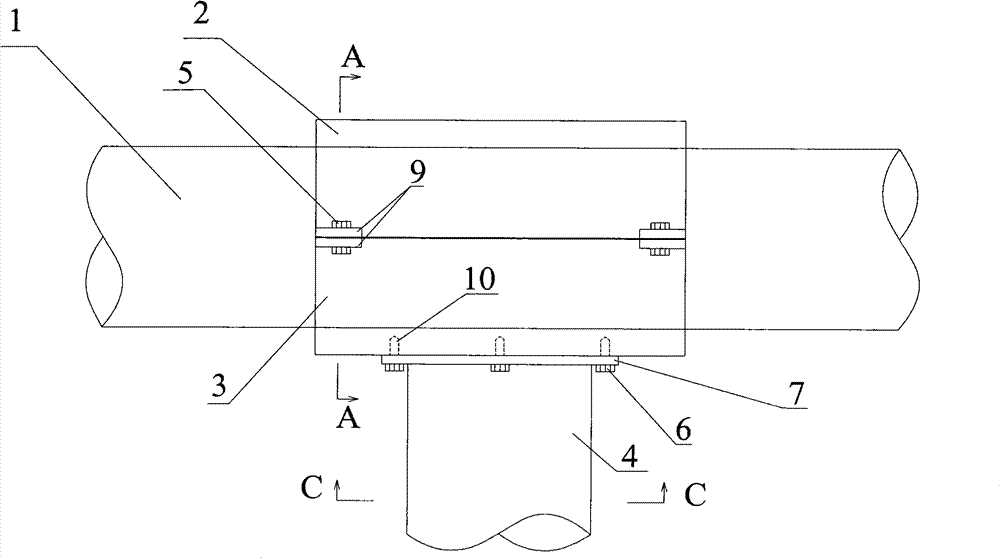

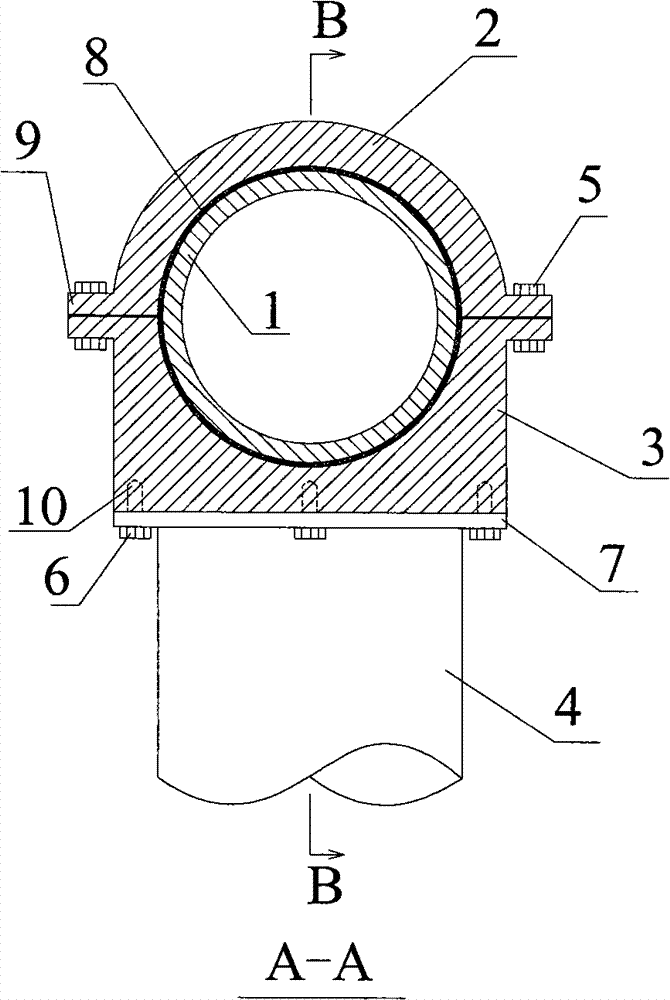

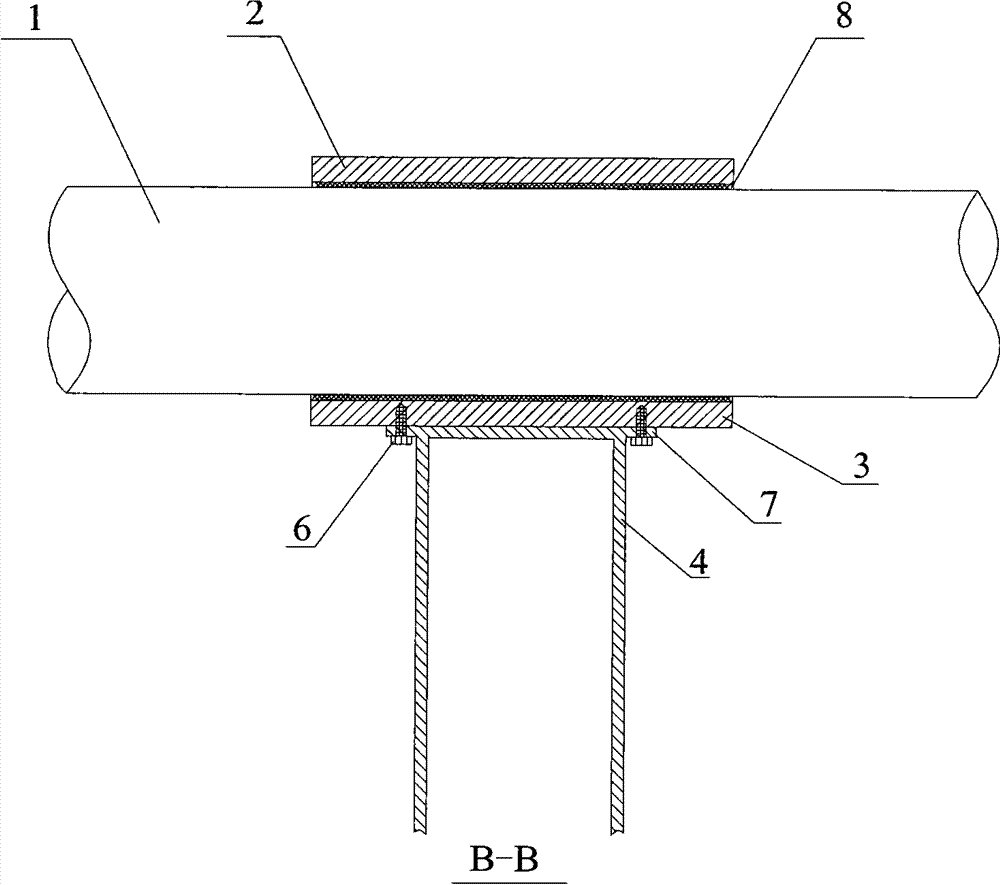

[0017] The invention is used to fix the submarine pipeline and prevent buckling propagation through the method of installing anti-bending fixers at intervals on the submarine pipeline. The main steps are as follows:

[0018] According to the outer diameter and wall thickness of the submarine pipeline to be protected, an inverted U-shaped shell with the same inner diameter and tangent outer edge can be manufactured, and the upper shell and the lower base can be mass-produced through two molds.

[0019] First, wrap a layer of rubber on the outer surface of the pipe, attach the upper shell to the rubber layer on the surface of the pipe, and connect it to the lower base according to the position of the eye plate, and then pass through the eye plate through 4 sets of matching bolts and nuts. Two housings are fixed to the pipe.

[0020] During the pipe laying operation, the barrel structure is inserted into the seabed soil by negative pressure sinking. Adjust the position of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com