Mold for producing DVD magnetic heads

A mold and magnetic head technology, applied in optical recording head, optical head manufacturing, etc., can solve the problems of small product, high DVD performance defect rate, long runner distance, etc., and achieve the effect of stable size and small appearance defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

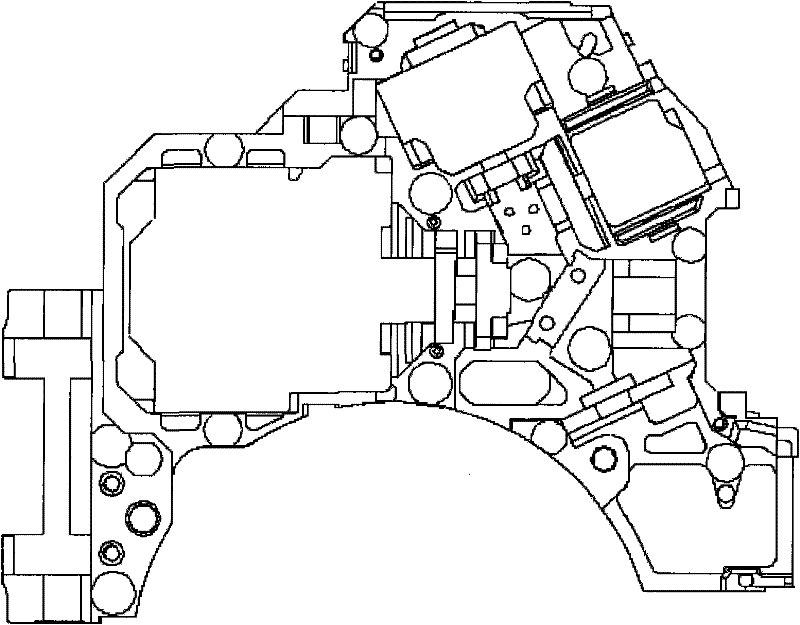

Image

Examples

Embodiment Construction

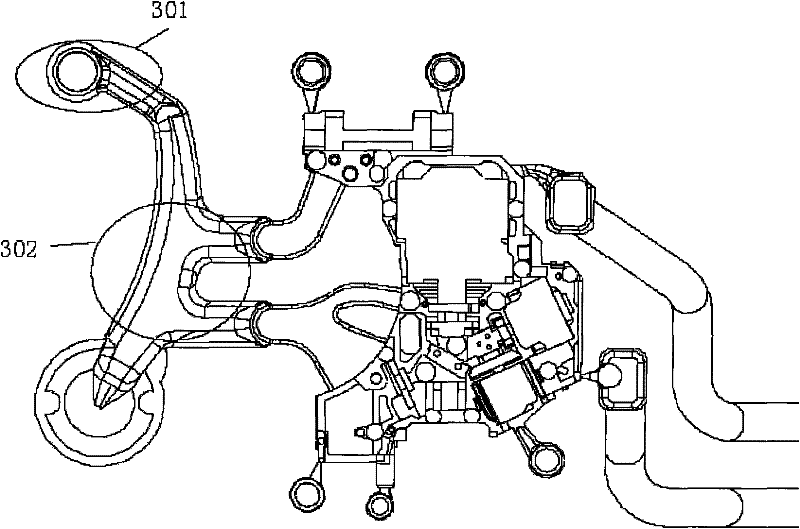

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] Depend on image 3 It can be seen that the present invention includes: a runner 301; the corresponding product of the runner 301 is one mold and one cavity; the end of the runner 301 also includes a cold material storage part 302; the distance between the runner 301 Between 48mm-52mm, the cross-sectional area of runner 301 is 28mm 2 -32mm 2 between.

[0016] In the present invention, the product is changed from one mold with two cavities to one mold with one cavity. The pressure in production can be reduced appropriately, which can effectively control the stability of product size and greatly improve the performance of DVD.

[0017] The runner is shortened from the original 100mm to about 50mm, and the cross-sectional area of the runner is reduced from the original 60mm 2 Change to the current 30mm 2 . The improvement here not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com