Steering knuckle with pre-sealing

A wheel bracket and front seal technology, which is applied in the direction of wheels, hubs, casters, etc., can solve the problems of increasing fuel consumption, and achieve the effects of simple installation, fewer components, and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

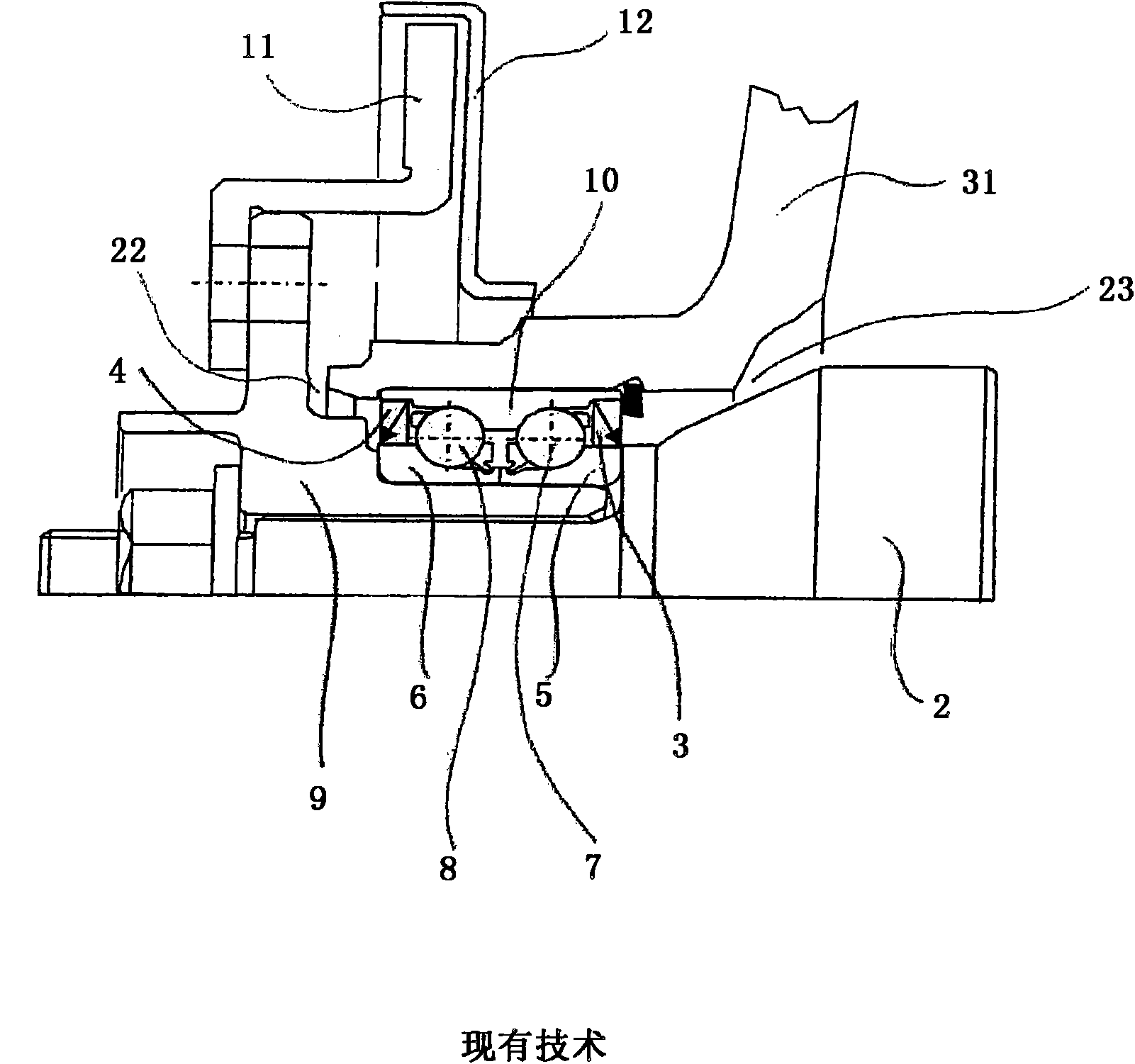

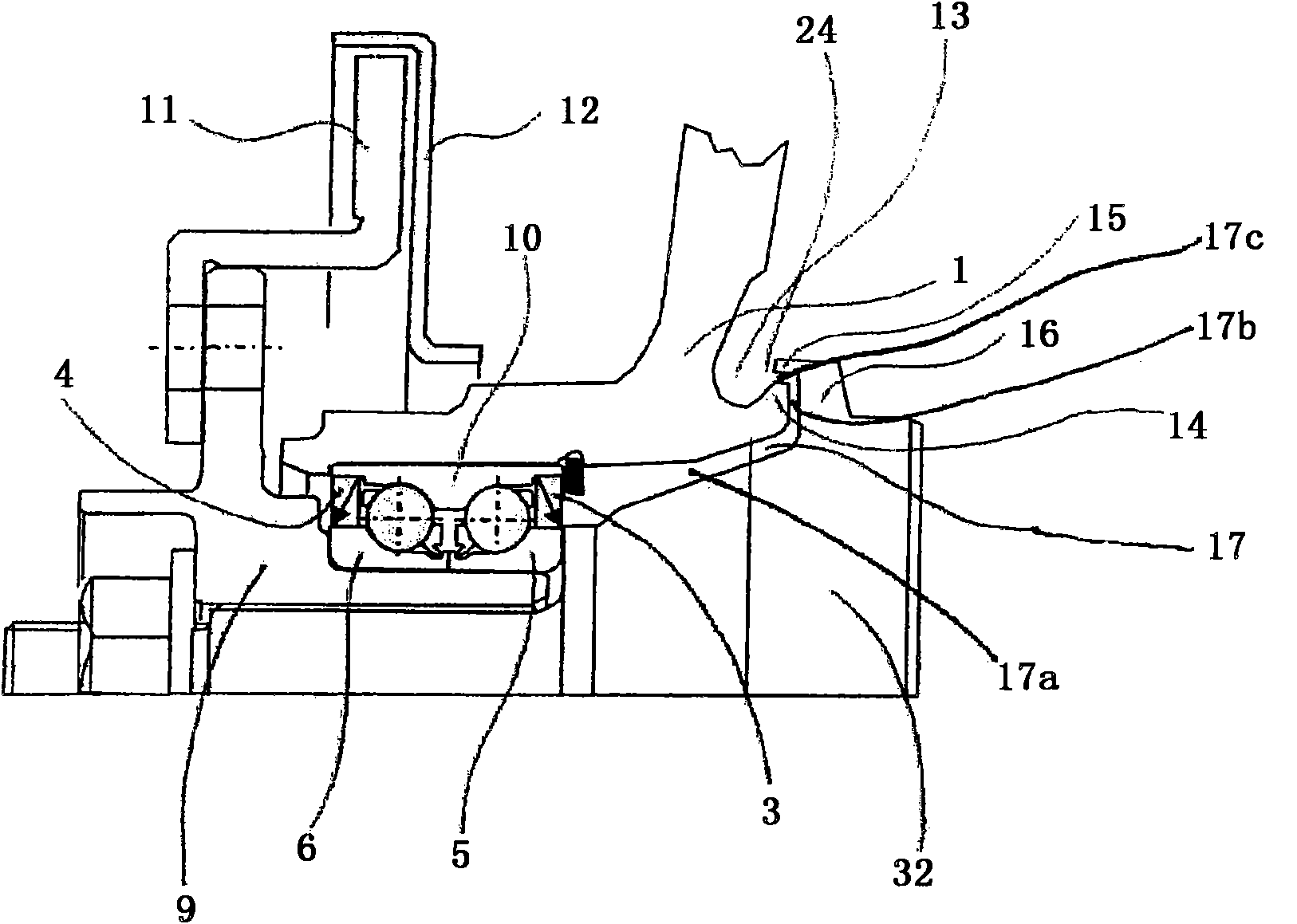

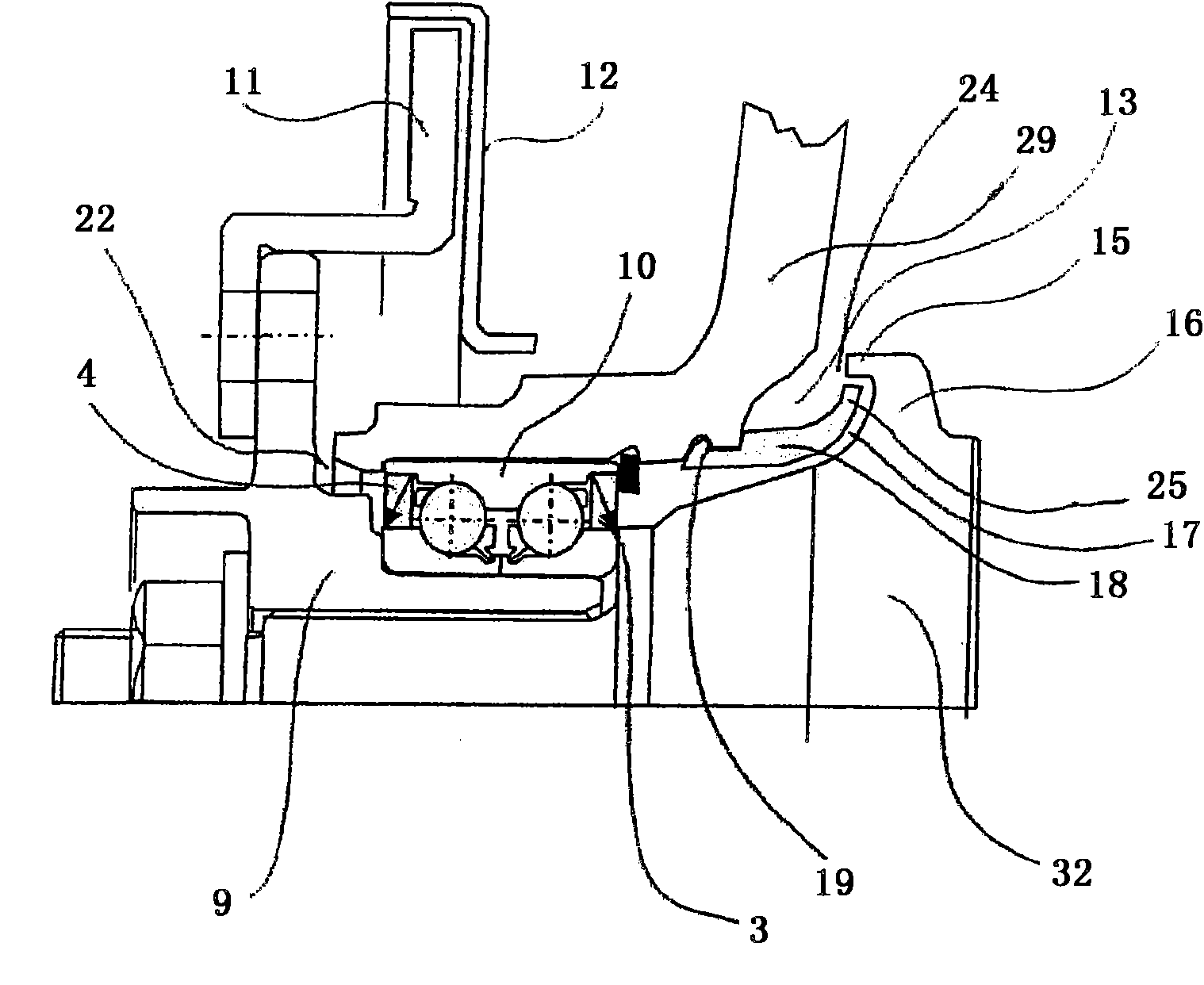

[0033] figure 1 A sectional view of a wheel bearing arrangement with two rows of angular contact ball bearings according to the prior art is shown.

[0034] The wheel bearing consists of two rolling element rows 7 , 8 , two inner rings 5 , 6 and an outer ring 10 . A seal 3 is arranged between the transmission-side inner ring 5 and the outer ring 10 , which seal protects the wheel bearing against environmental influences which act via the transmission-side gap 23 between the wheel carrier 31 and the joint cover 2 on wheel bearings. Accordingly, a wheel-side seal 4 is situated between the wheel-side inner ring 6 and outer ring 10 , which seal protects against environmental influences which act via the wheel-side gap 22 between the wheel hub 9 and the wheel carrier 31 on wheel bearings. Compared with the transmission-side gap 23 , the wheel-side gap 22 is in a relatively protected position, in particular because it passes through the wheel flange of the wheel hub 9 or throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com