Non-aligned row cotton stalk harvester and cotton stalk pulling harvesting table thereof

A harvesting table and harvester technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of high energy consumption, large digging effect, and large wear of planers, and achieves good harvest adaptability and digging. Small effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

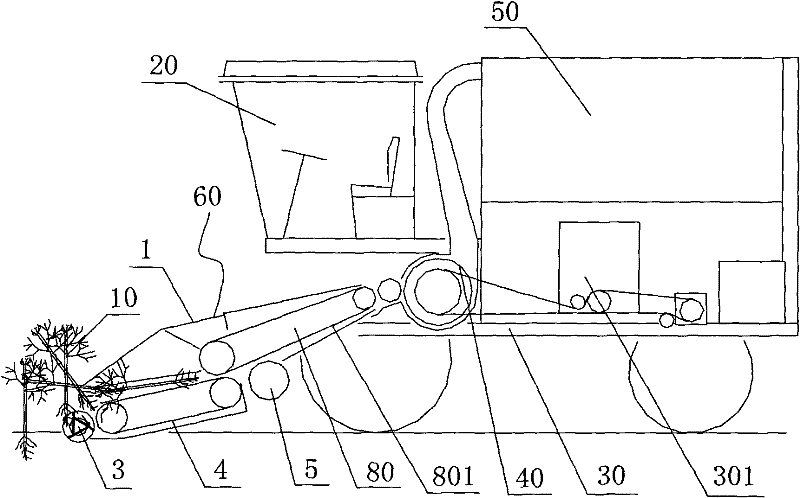

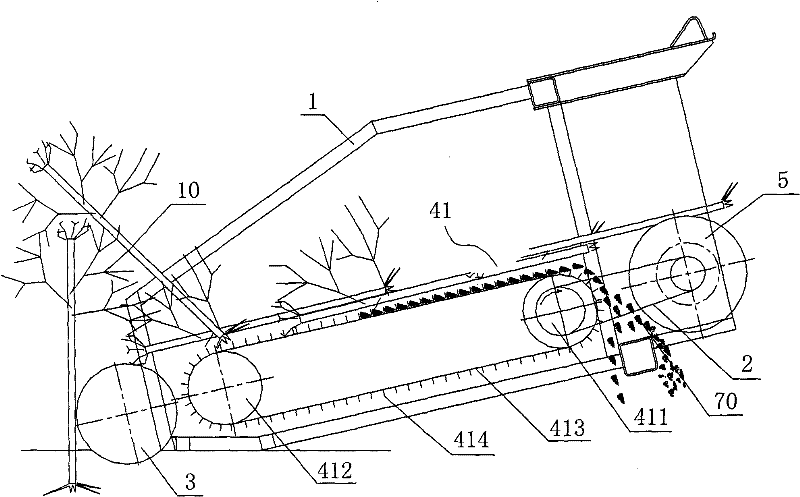

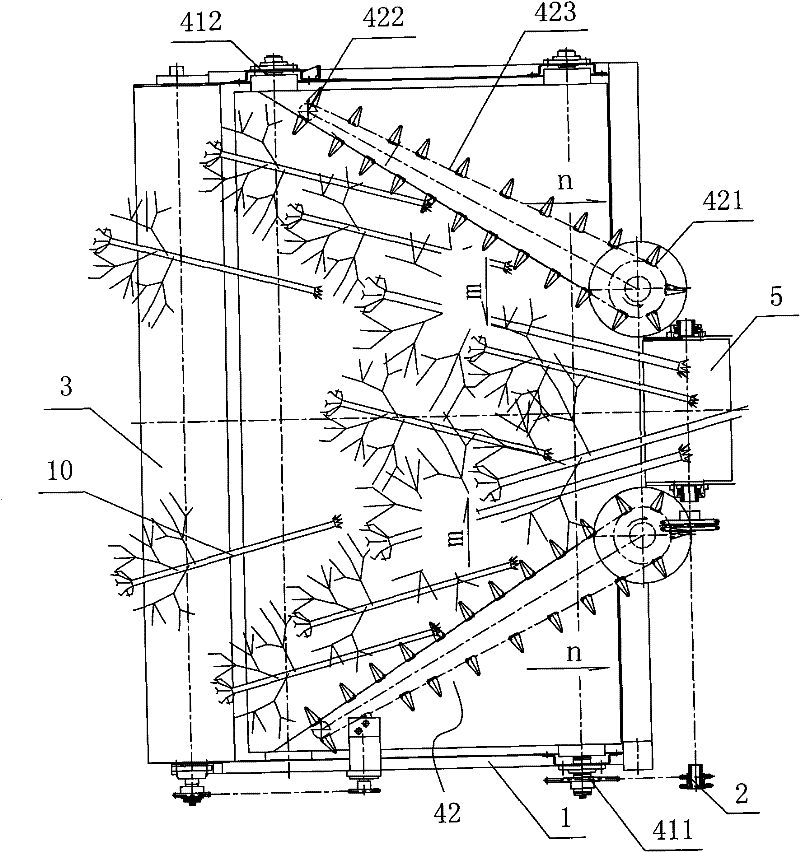

[0079] see figure 1 , figure 1 It is a structural schematic diagram of the non-aligned cotton stalk harvester of the present invention. The non-aligned cotton stalk harvester of the present invention includes a cab 20, a walking chassis 30, a cotton stalk extraction and harvesting platform 60, a conveying trough 80, a chopping device 40, and a collecting device 50. The front part above the chassis 30, the chopping device 40 and the material collecting device 50 are installed on the walking chassis 30 and set behind the driver's cab 20, and the cotton stalk extraction and harvesting platform 60 is set on the conveying The front end of the trough 80 is connected to the chopping device 40 through the conveying trough 80, the chopping device 40 is connected to the collection device 50, the cotton stalk extraction harvesting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com