Cambered plate type gas-solid phase reactor

A bow-shaped plate and reactor technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex structure of the disc gas-solid phase reactor, inability to industrialize application, and high reactor cost, and achieve convenient regulation and control. , The effect of large operation flexibility and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

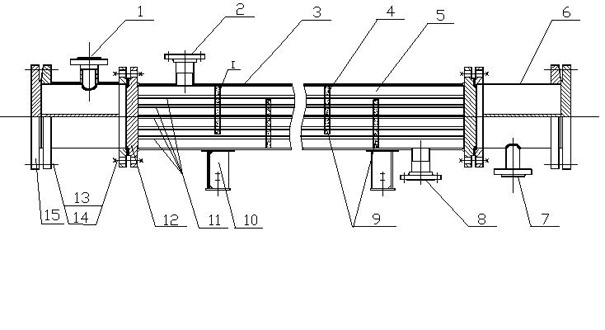

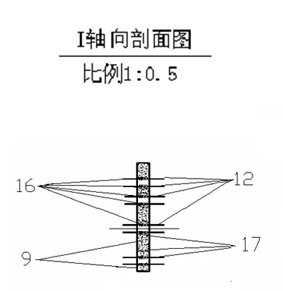

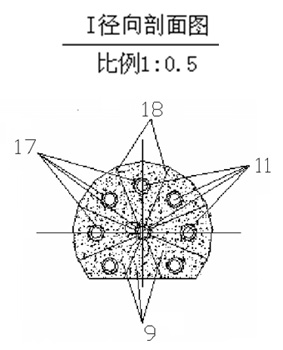

[0032] The bow-shaped plate gas-solid phase reactor of the present invention can be placed horizontally or vertically. The bottom of the horizontal shell is provided with a base, and the outer wall of the vertical shell is provided with suspension supports. The gas-phase inlet and gas-phase outlet of the gas-solid phase reaction are headed tube boxes, the gas circulates in the tube, and the reaction gas-phase inlet and gas-phase outlet at both ends are connected with the shell; the shell is arranged in concentric circles or regular triangles. The root reaction gas pipe, the tube side is used as the passage of the reaction / generated gas; the outlet and the inlet of the fluid are respectively arranged on both sides of the shell, and the shell side is used as the passage of the heat exchange fluid; the tube side of the trachea is arranged at a certain distance in the axial direction. The arcuate plate, the space inside the plate is used to fill the solid phase reactant, which is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com