Waterproof, dustproof and shockproof telephone receiver net and manufacturing process thereof

A production process and earphone net technology, which is applied in the directions of lamination auxiliary operation, lamination, and layered products, etc., can solve the problems of reducing dustproof effect, internal circuit damage, drop, etc., to improve the safety of use, good reduction Vibration, anti-dropping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

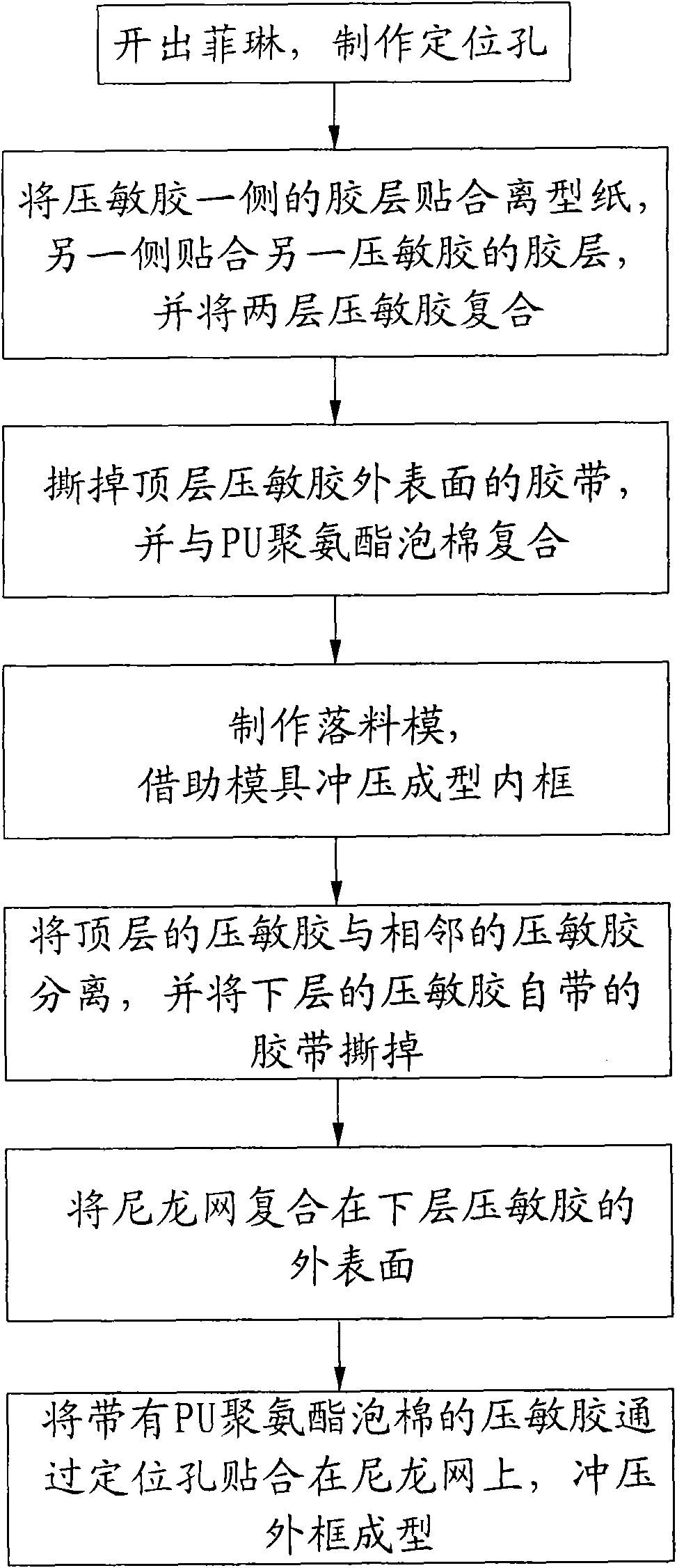

[0027] The structure and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

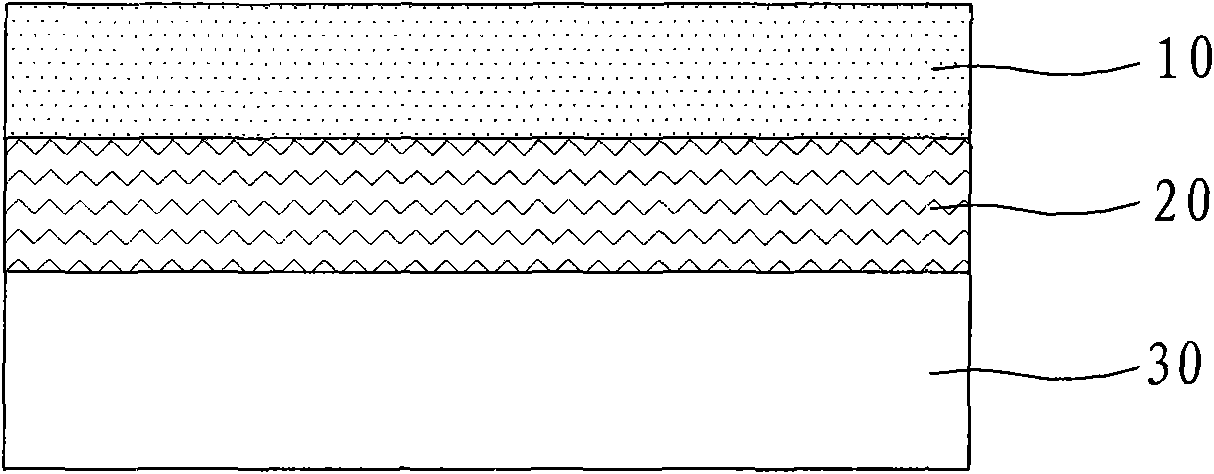

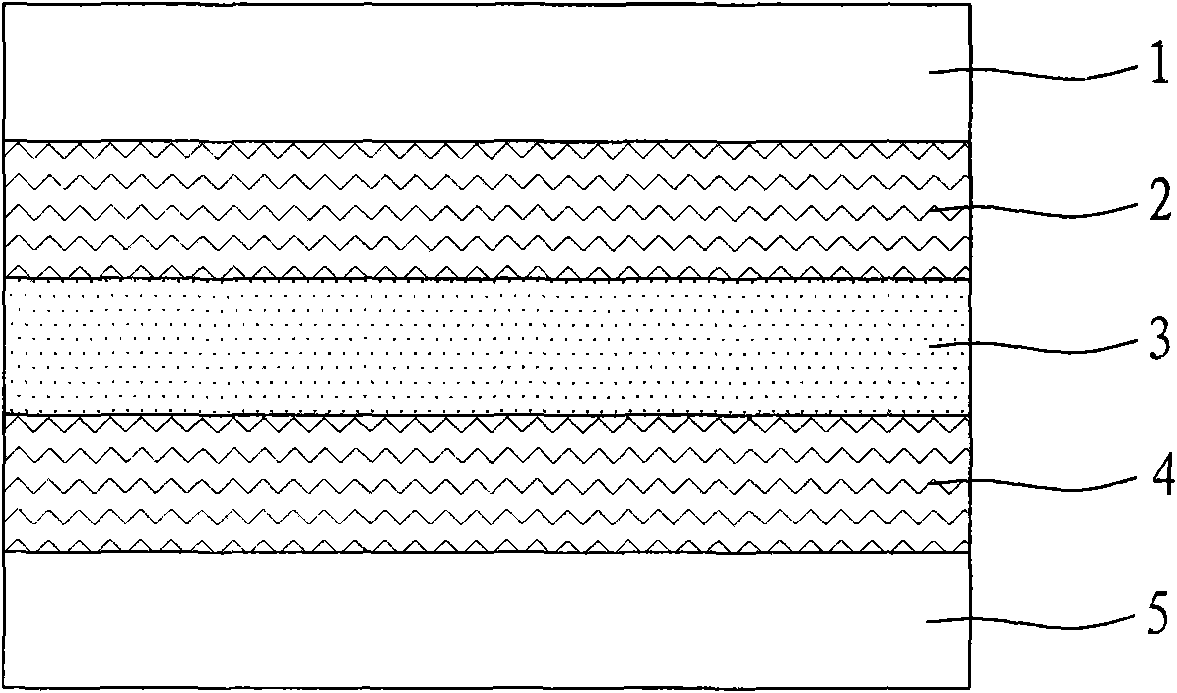

[0028] Such as figure 2 As shown, the present invention provides a waterproof, dustproof and shockproof earpiece net, comprising a foam layer 1, a first pressure-sensitive adhesive layer 2, a nylon mesh layer 3, a second pressure-sensitive adhesive layer 4 and a release layer laminated in sequence. Pattern paper layer 5 is introduced respectively below.

[0029] The foam layer 1 is arranged on the outer surface, adopts PU polyurethane foam, and its thickness is designed to be 0.15-0.7mm. In the present invention, it is used as a shock absorber to effectively prevent the handset net from falling off due to vibration during exercise.

[0030] The first pressure-sensitive adhesive layer 2 is used to bond the foam layer 1 and the nylon mesh layer 3 together, and its thickness is designed to be 70-120 μm, and together with the foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com