Low-noise blower

A low-noise, blower technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of little noise, increased noise, limited effect, etc., to achieve enhanced sound absorption, enhanced support, and reduced reflection The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

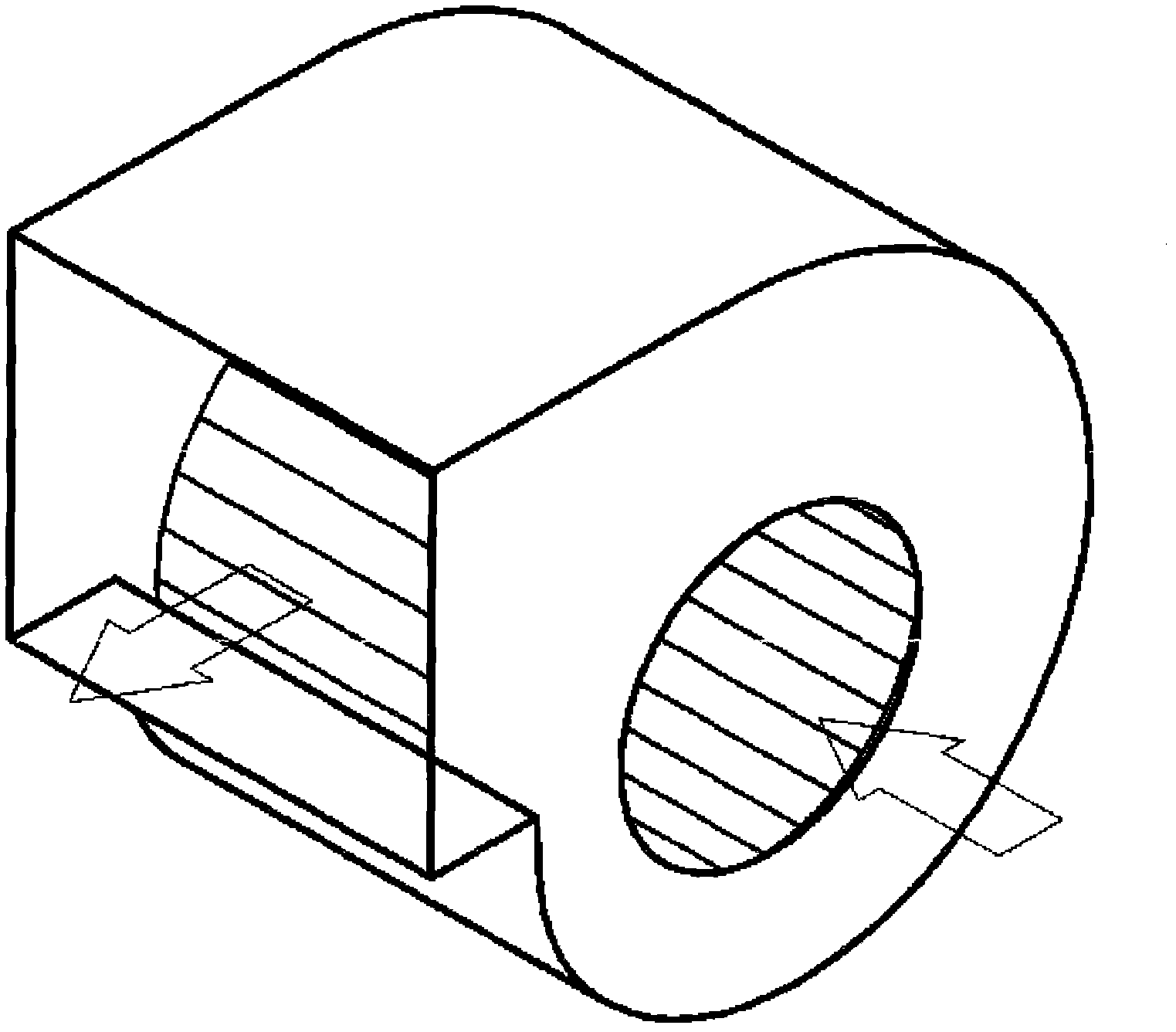

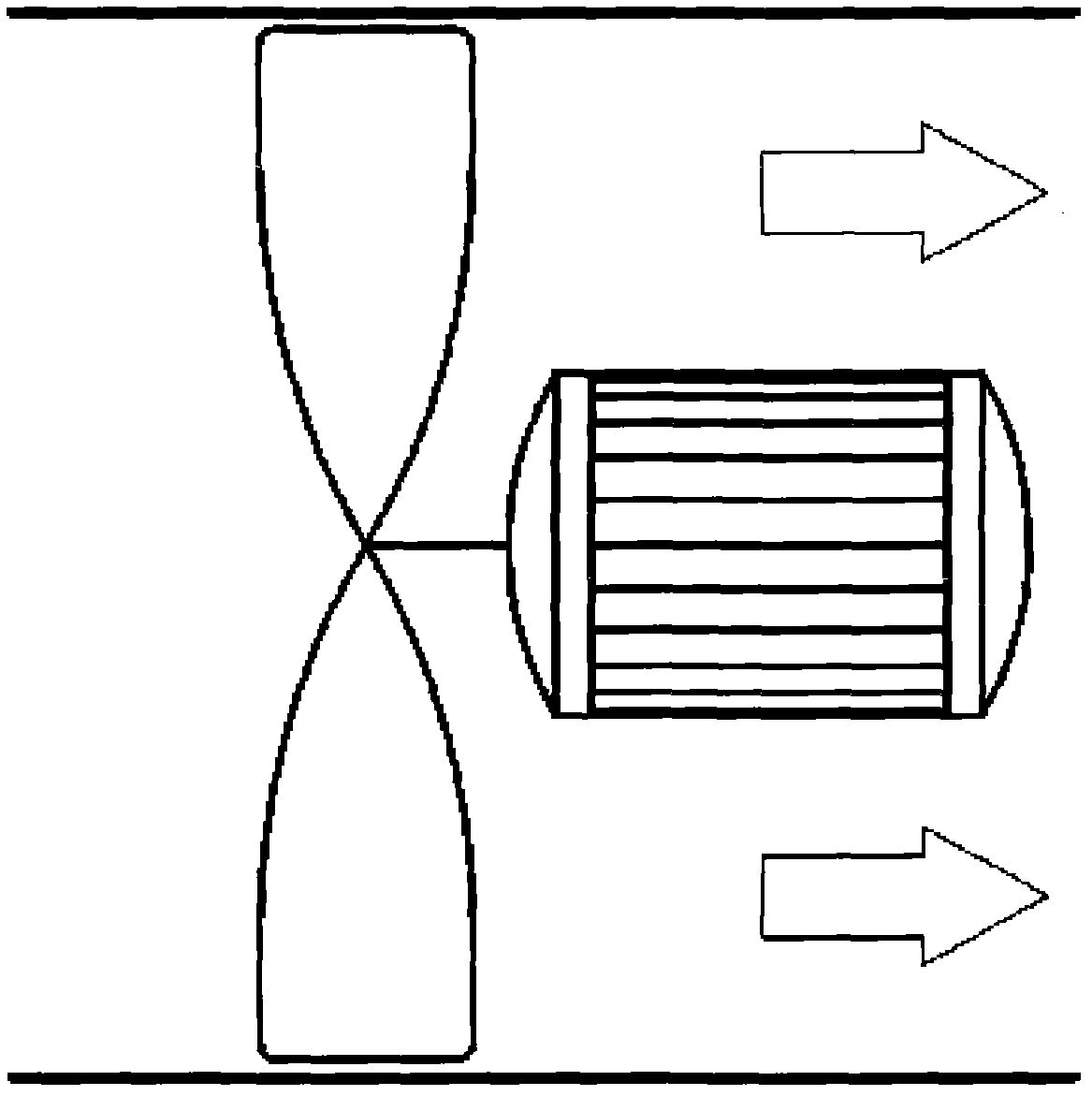

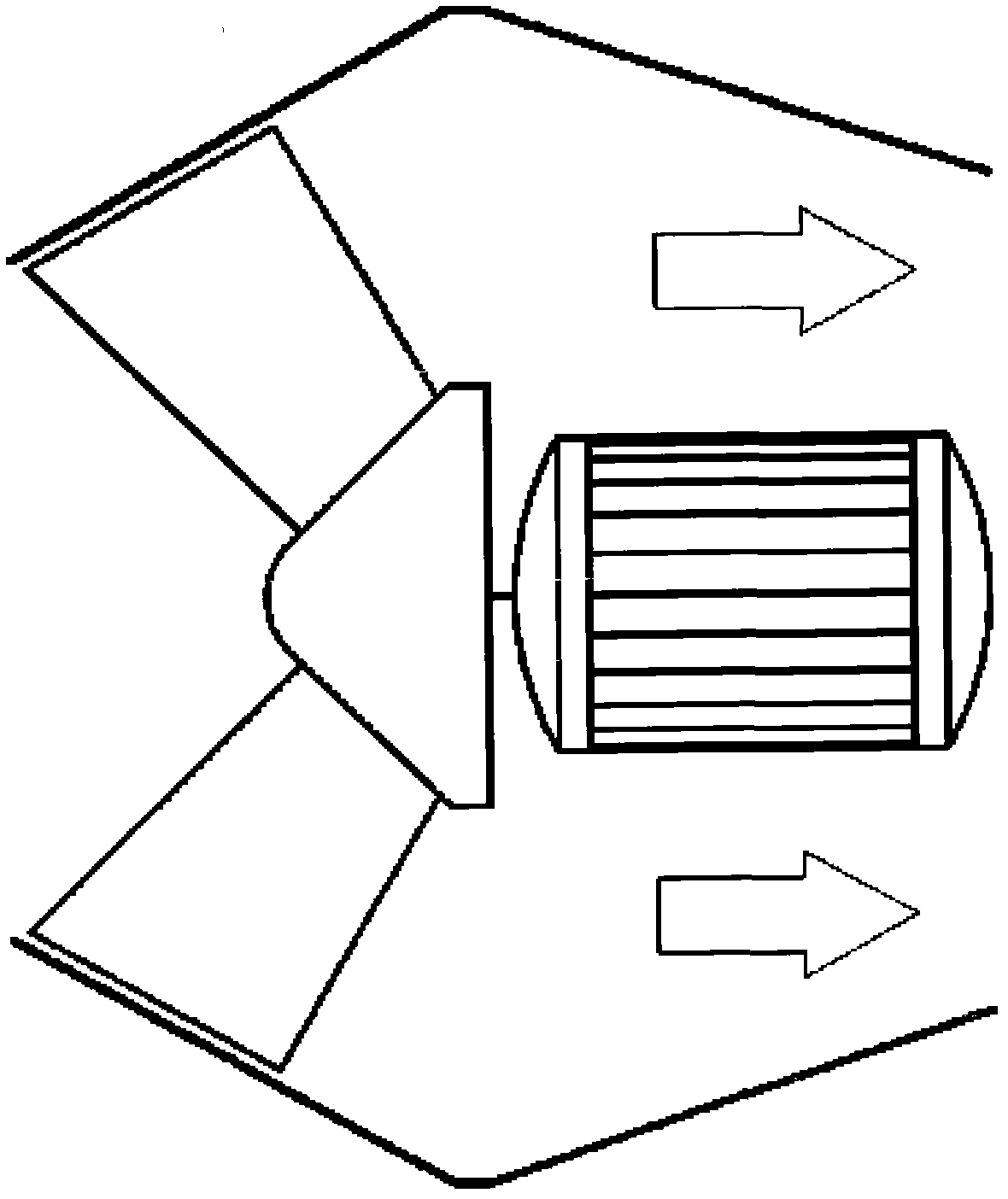

[0039] The specific structure of the low noise fan is as follows: Figure 7-9 As shown, the centrifugal, axial flow and mixed flow low-noise fans all include a shell with noise reduction function. The shell is a sandwich structure, the inner wall of which is a sound-absorbing surface 10, and the interlayer is a sound-absorbing filler 20. Specifically, the housing includes an inner shell and an outer shell, the outer shell is made of airtight material, the inner shell is made of porous or mesh plate material, the sound-absorbing filler 20 is filled between the inner shell and the outer shell, and the multiple holes on the inner shell Or the meshes are staggered, so that any line parallel to the airflow direction on the inner shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com