Electromagnetic brake with permanent magnet

An electromagnetic brake and permanent magnet technology, which is applied in the direction of brake types, brake components, brake actuators, etc., can solve the problems of easy magnetic flux leakage, shortened service life, and poor installation of permanent magnetic steel structures, and achieve stability Good, longer life, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

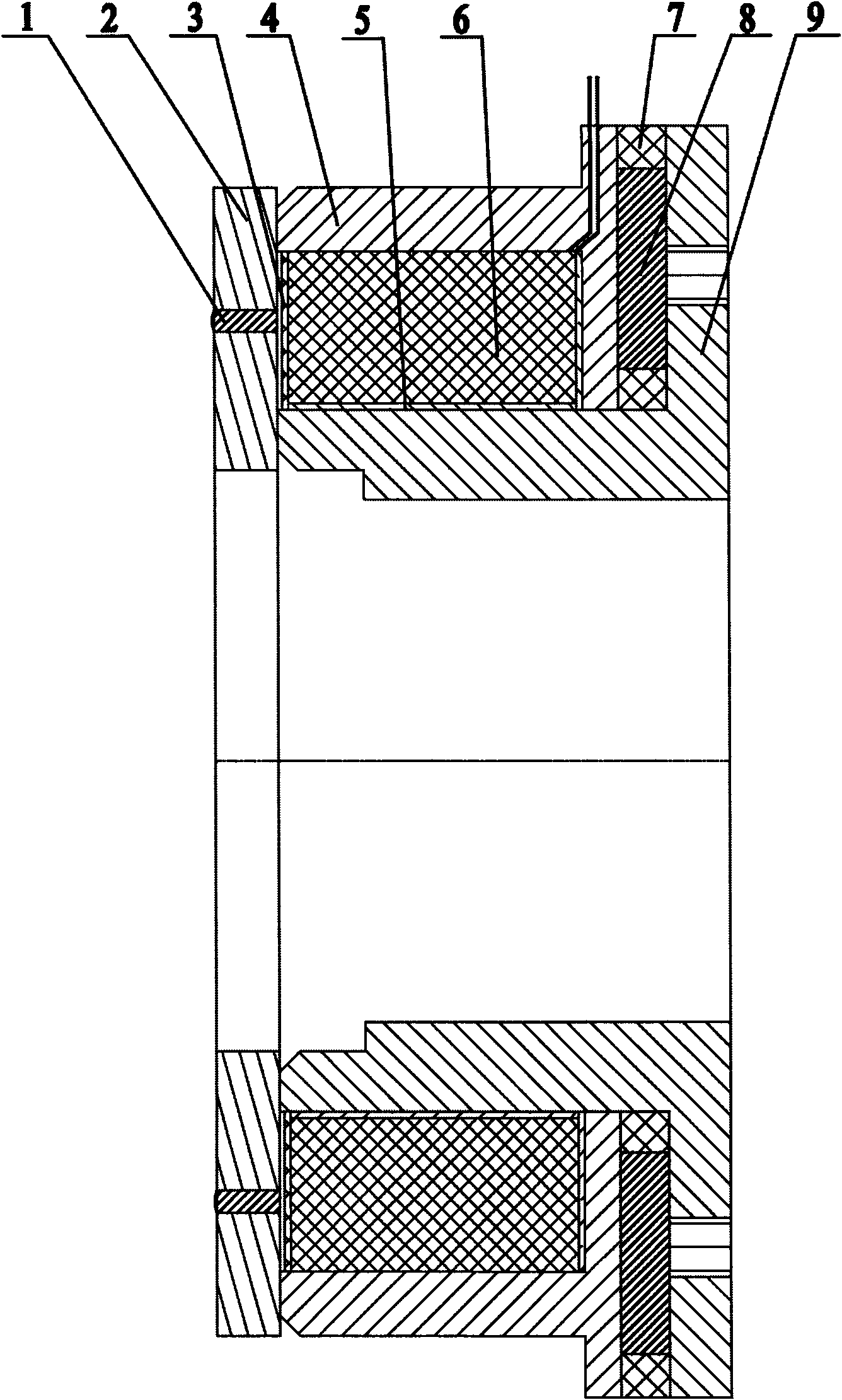

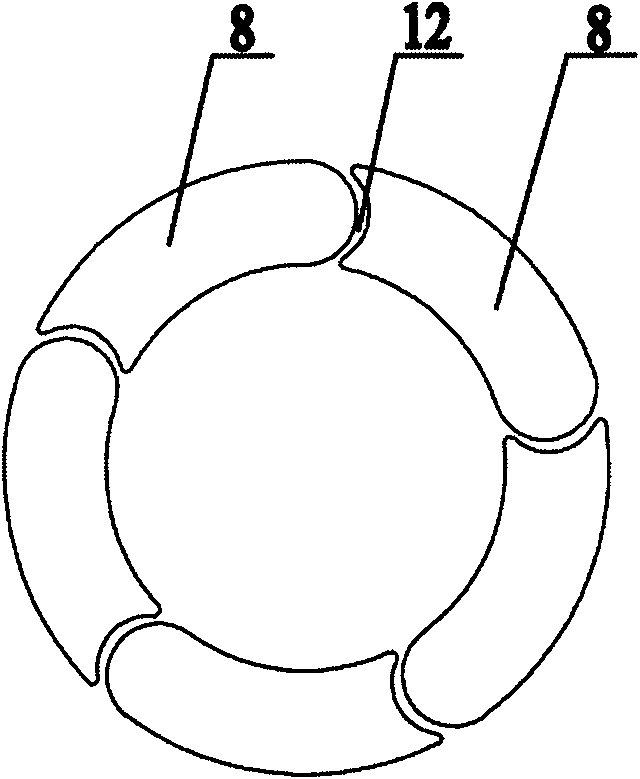

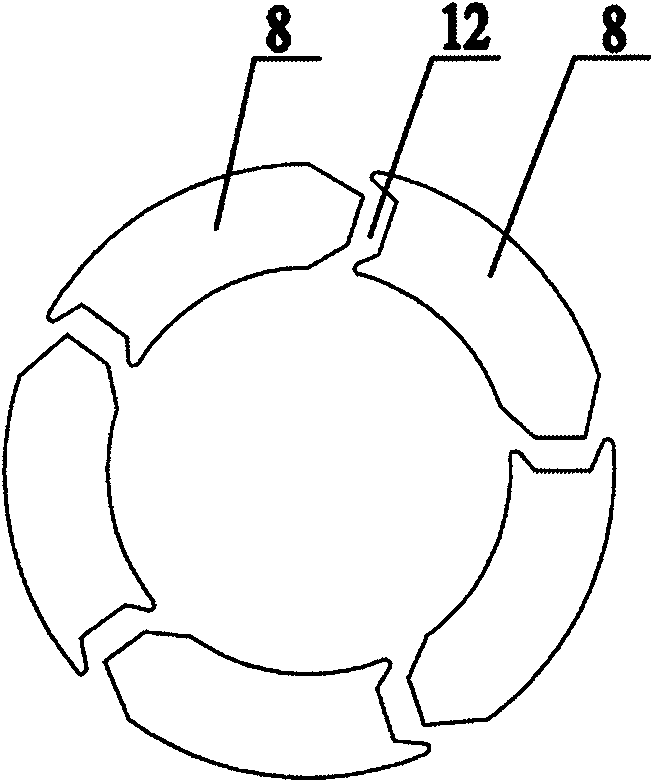

[0015] As shown in the figure, the present invention mainly consists of a spring plate 1, a friction plate 2, a coil baffle 3, a frame 4, a coil lining 5, a coil 6, a magnetic steel skeleton 7, a magnetic steel 8, a machine base 9, a rivet 10, The fixing hole 11, the anti-magnetic flux leakage channel 12, the fixing ring 13 and other components are composed.

[0016] The electromagnetic brake with permanent magnets includes a spring plate 1, a friction plate 2, a coil baffle 3, a frame 4, a coil lining 5, a coil 6, a magnetic steel skeleton 7, a magnetic steel 8 and a machine base 9. The leaf springs 1 are provided with fixing holes 11, and several leaf springs 1 are installed on the corresponding positions in the friction plate 2 through rivets 10; Coil 6 is arranged between, and the inner wall of coil 6 has coil liner 5, and coil baffle plate 3 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com