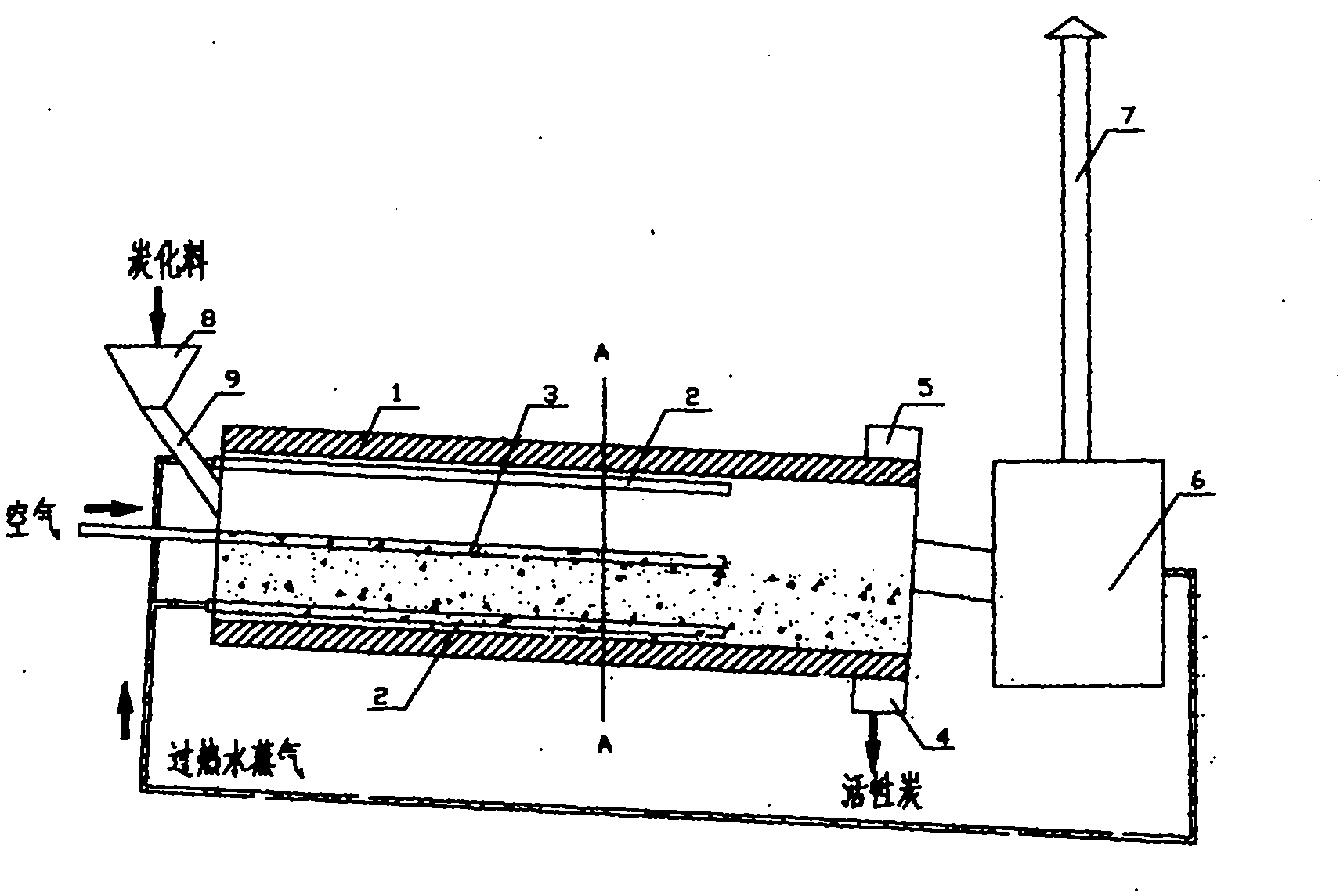

Novel rotary activation furnace

An activation furnace and activation temperature technology, applied in the field of new rotary activation furnaces, can solve the problems of low product adsorption performance, low thermal energy utilization efficiency, complex equipment structure, etc., and achieve low equipment cost, product quality improvement, and long activation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

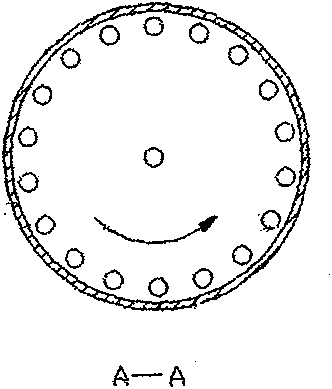

Method used

Image

Examples

Embodiment 1

[0013] 6-10 mesh coconut shell carbonization materials are continuously added into the novel rotary activation furnace of the present invention from a hopper, and after being fed into air-water vapor for activation, the product activated carbon is discharged from the belt-type sealing discharge device 5 and the discharge port 4, and the product Iodine adsorbate 1300mg / g, methylene blue adsorption capacity 15ml.

Embodiment 2

[0015] 10-30mm charcoal particles are continuously added into the novel rotary activation furnace of the present invention by a hopper, and after being fed into air-water vapor for activation, the product activated carbon is discharged from the belt-type sealed discharge device 5 and the discharge port 4, and the product iodine adsorbate 1350mg / g, methylene blue adsorption capacity 17ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com