Hole sowing machine

A technology of hole seeder and seed storage, applied in the field of hole seeder, can solve the problems of inapplicability to small-area farmland, complex structure, inconvenient transportation, etc., and achieve the effect of promoting stable and high yield, small size, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

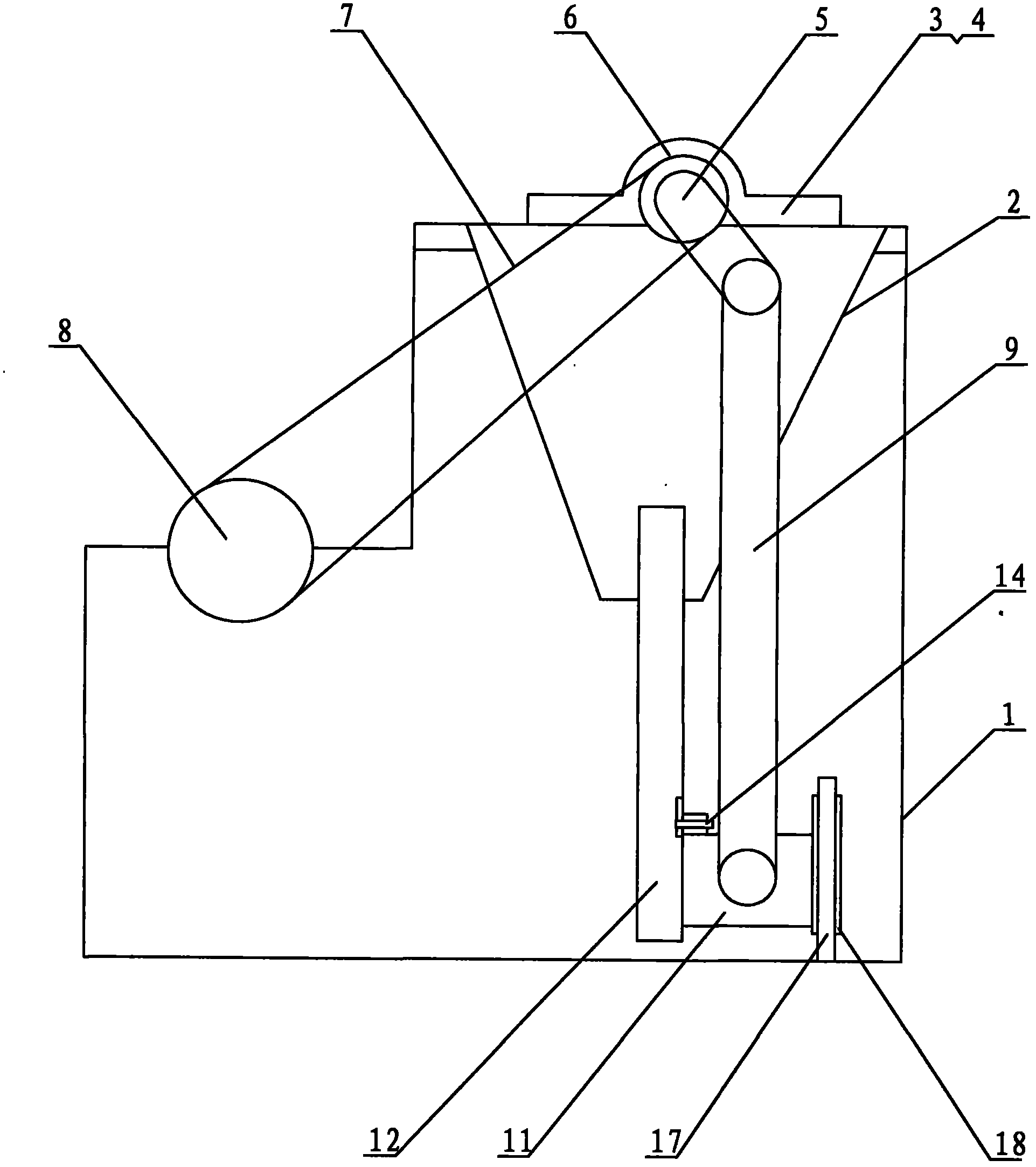

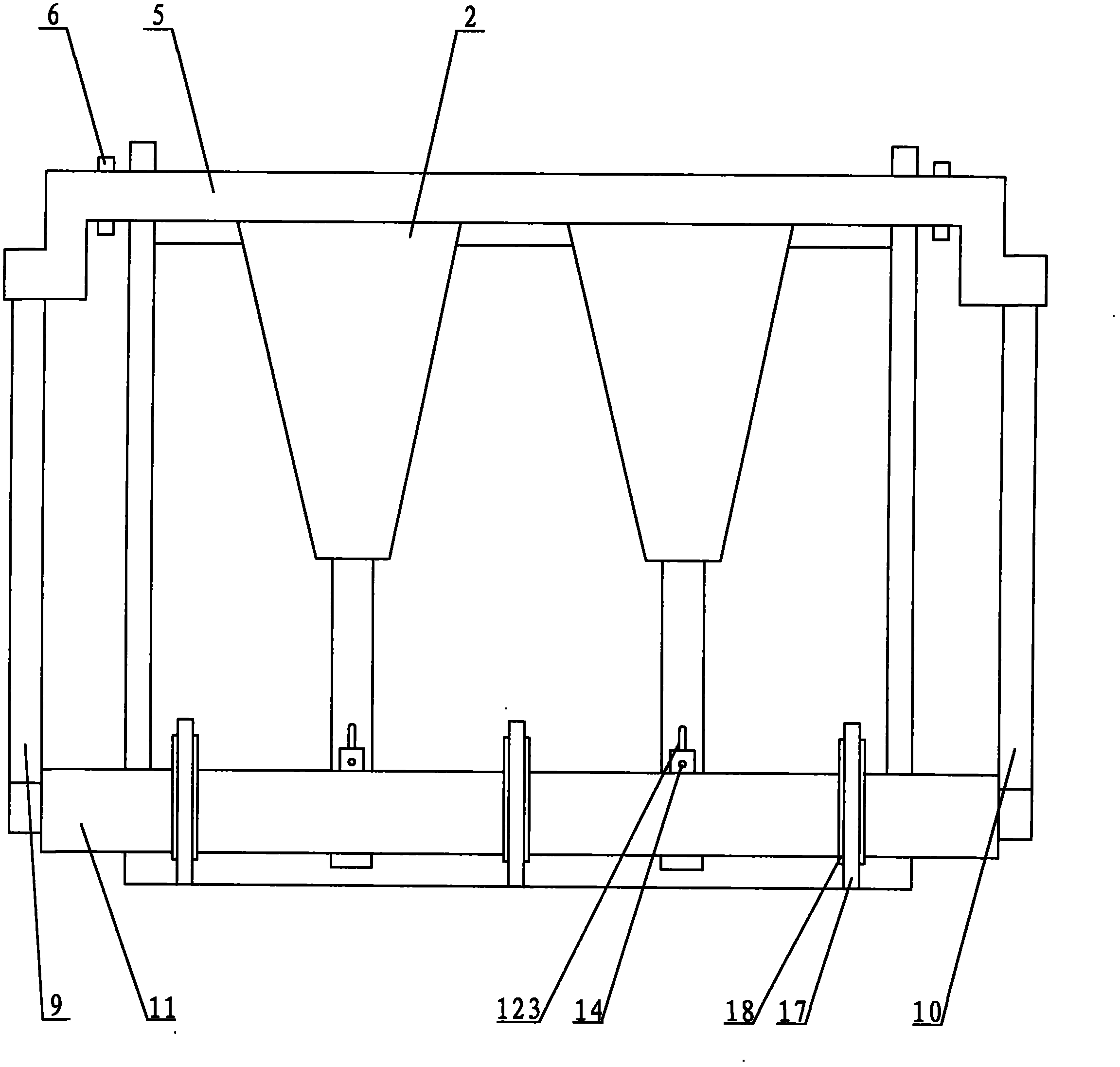

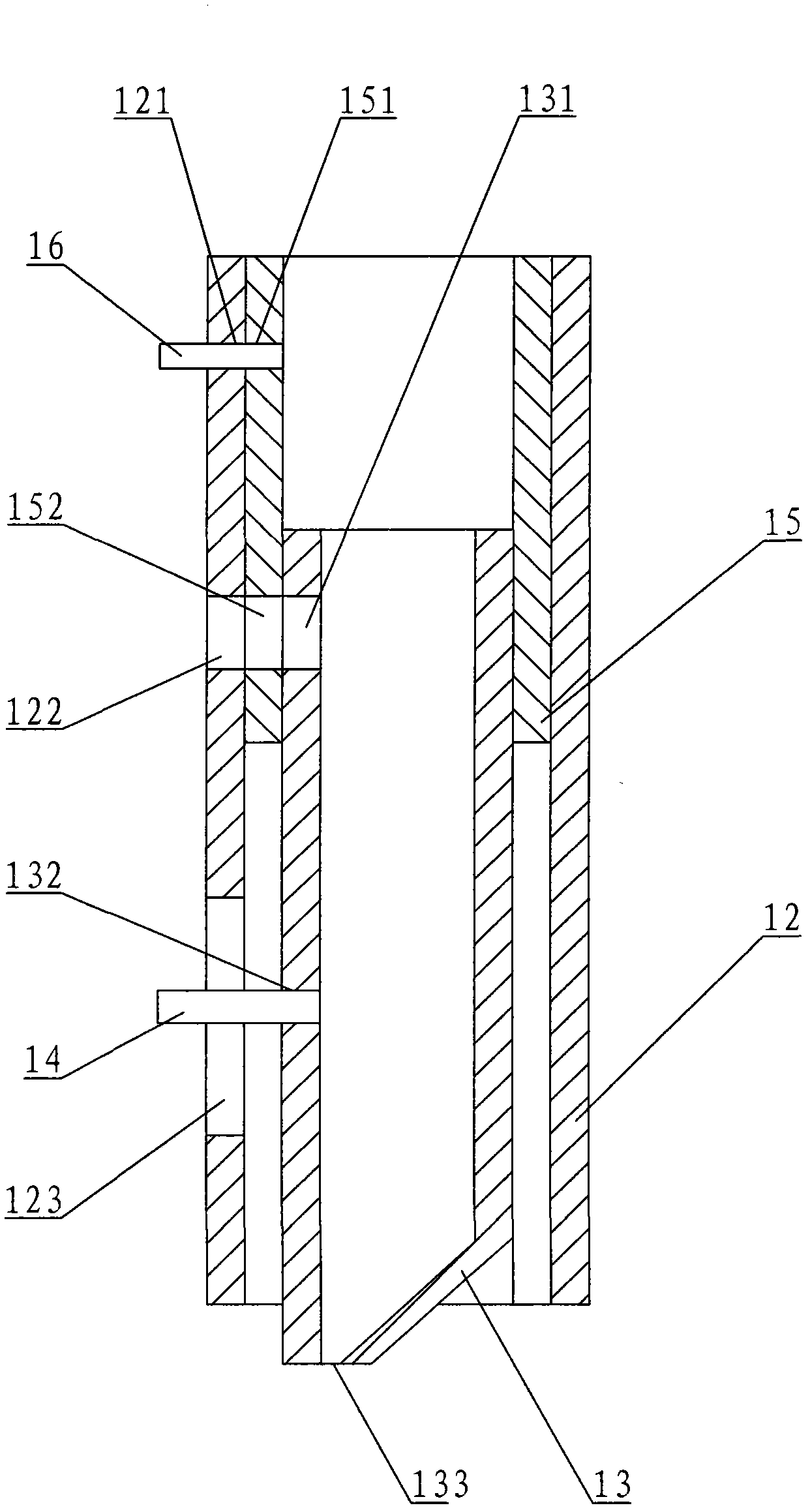

[0014] Figure 1-3 As shown, a hole seeder mainly includes a frame 1, a seed storage bucket 2, a bearing seat 3, a bearing 4, a crankshaft 5, a gear 6, a tooth chain 7, a power input shaft 8, vertical connecting rods 9, 10, and a lifting cross arm 11 , protective tube 12, seed delivery tube 13, lifting pin 14, regulating tube 15, positioning pin 16, lifting column 17 and lifting sleeve 18. The upper end of the frame 1 is connected to a crankshaft 5 through the bearing seat 3 and the bearing 4, and one end of the crankshaft 5 is connected to the power input shaft 8 through the gear 6 and the tooth chain 7. The lower ends of 9 and 10 are connected to the lifting cross arm 11; multiple seed storage buckets 2 are evenly arranged and supported in the frame 1, and the multiple seed storage buckets 2 are vertically connected to the protection pipe 12, and the protection pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com