Automatic overturning machine

A technology of automatic turning and turning mechanism, which is applied in the field of turning machines, can solve the problems of low degree of automation of the production line, unfavorable product market competition, complex structure of turning equipment, etc., and achieve the effect of high degree of automation, simple and firm structure, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

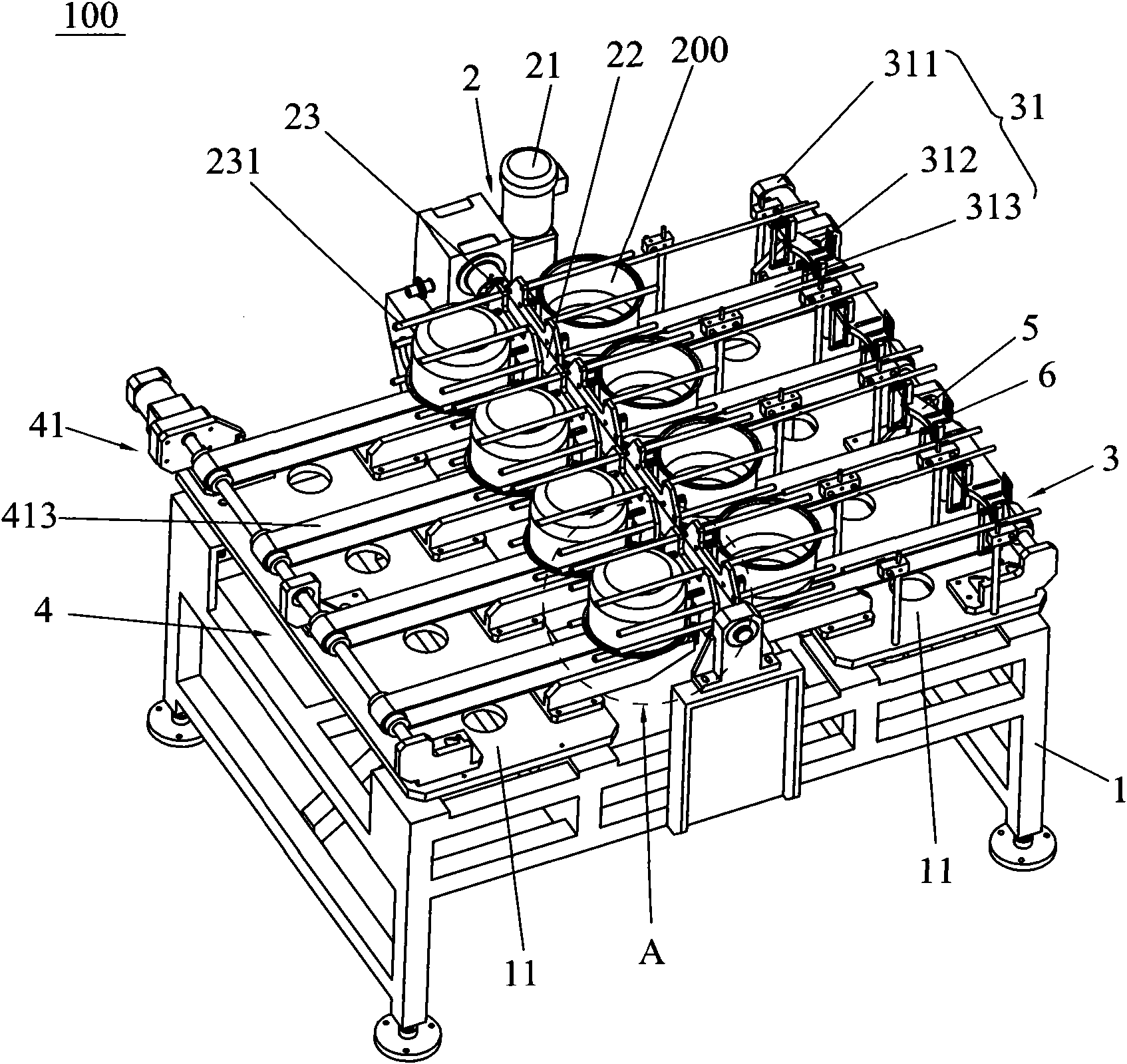

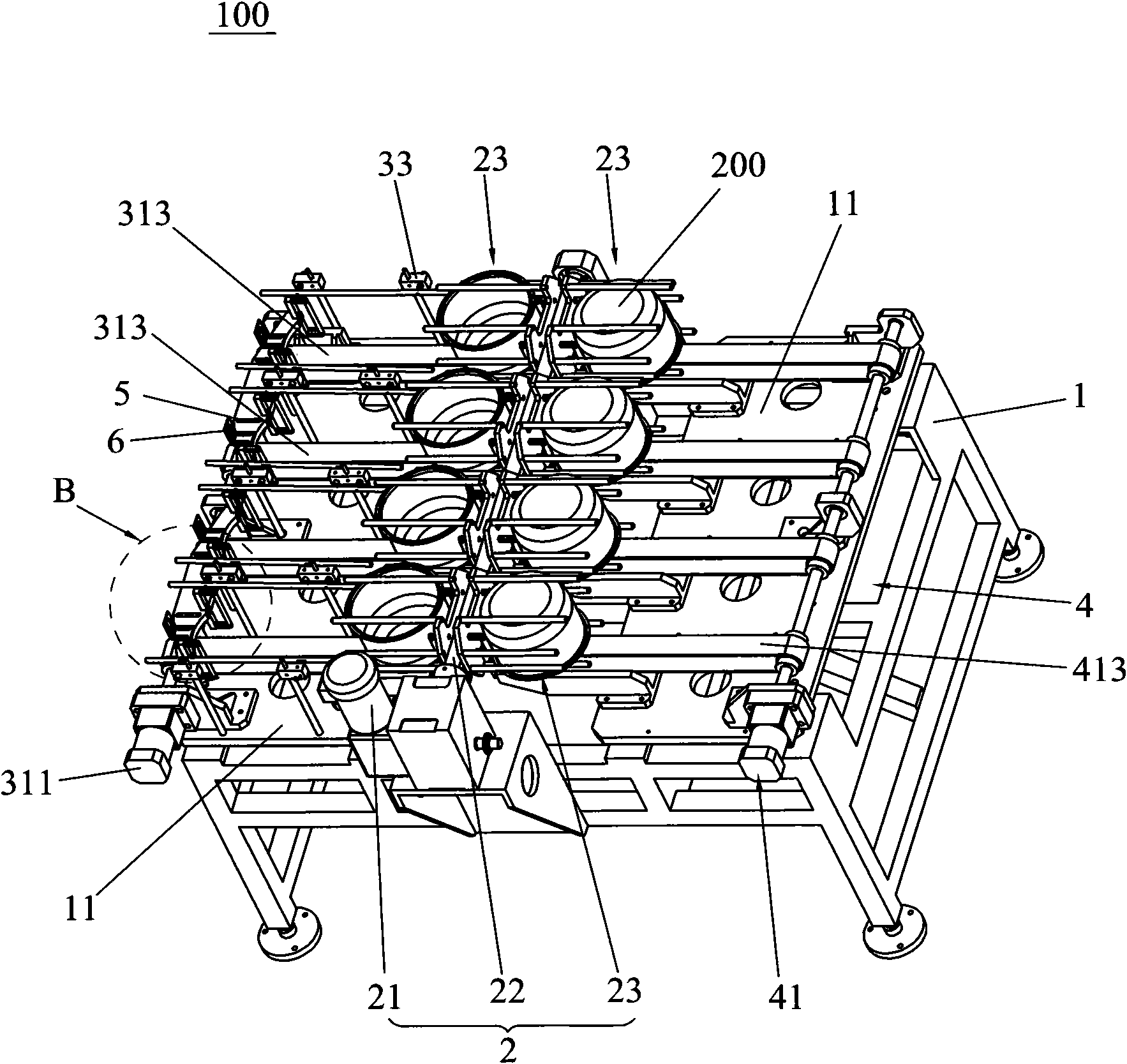

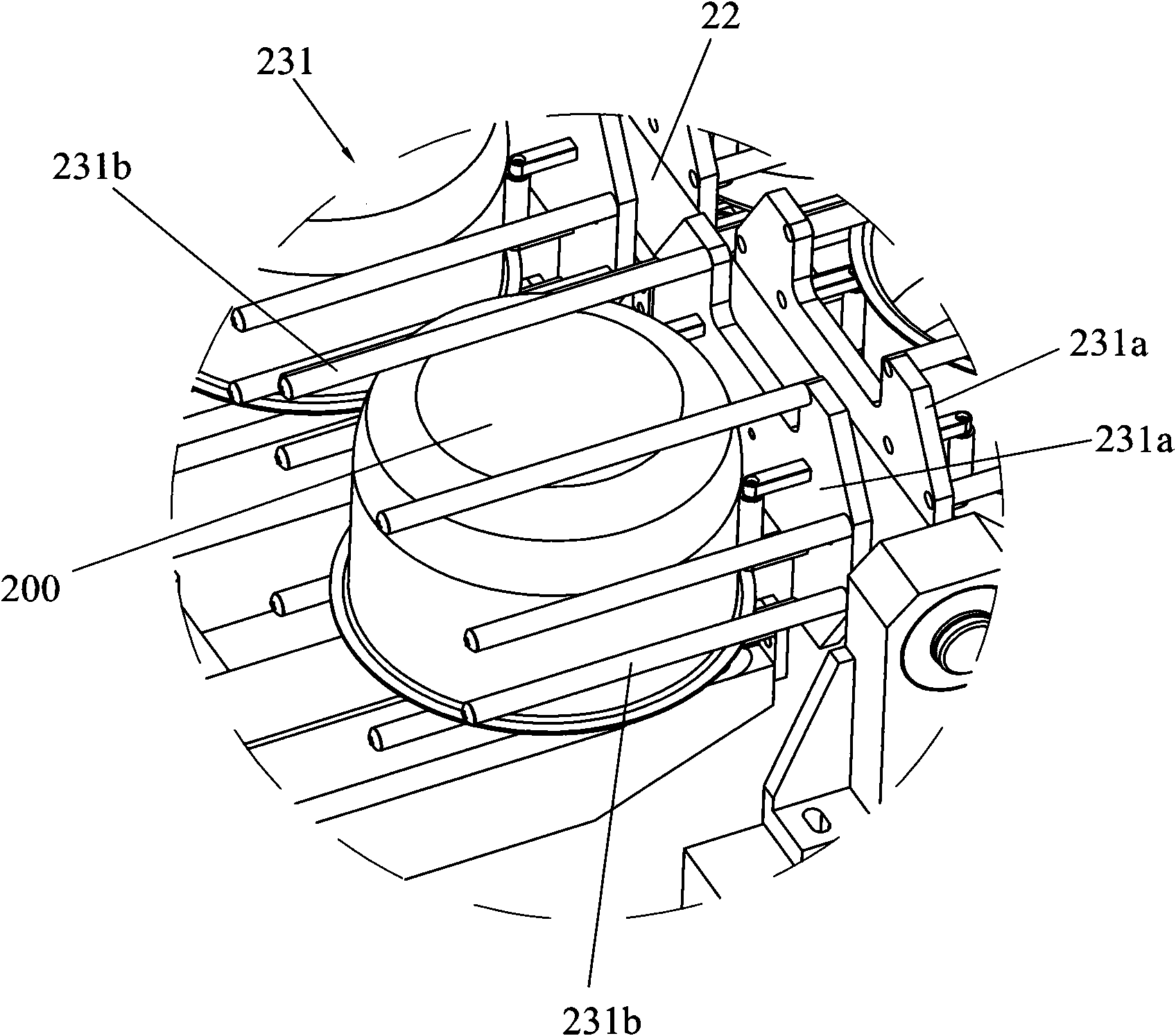

[0022] Such as figure 1 and figure 2 As shown, the automatic turning machine 100 of the present invention is used to turn over the aluminum pot 200 in the process of processing the aluminum pot 200, including a control system (not shown in the figure), a frame 1, a turning mechanism 2, an input mechanism 3, an output mechanism 4, Position the base plate 5 and the sensor 6, the turning mechanism 2 is arranged in the middle of the frame 1, the input mechanism 3 and the output mechanism 4 are respectively arranged on both sides of the turning mechanism 2 and installed on the frame 1, the turning mechanism 2 includes a turning motor 21, a turning shaft 22 and a clamp set 23 equipped with a clamp 231, the clamp set 23 is fixed on the turning shaft 22, and the clamp 231 clamps the aluminum pot 200, the turning motor 21 is coupled with the turning shaft 22 and drives the turning shaft 22 to rotate; the input mechanism 3 and the output mechanism 4 have the same drive assembly 31, 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com