Method for preparing immunocompetent soybean peptide by enzymolysis and membrane separation

A technology of immune activity and soybean peptide, which is applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of less research on immune activity peptides, and achieve the effect of improving the quality of immune activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

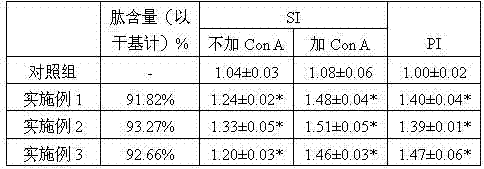

Examples

Embodiment 1

[0026] Low-temperature defatted soy flour is pickled 4 times. Add mass concentration 2g / LNa during pickling 2 SO 3 Solution, adjust the pH to 4.5, add pickling solution at 1:10 (w / v), temperature 55℃, washing time 10min, after pickling, centrifuge to remove the supernatant to obtain acid precipitation protein. After pickling the soy protein, add water at 1:10 (w / v), adjust the pH to 8.0 (in the process of adjusting to pH 8.0, the viscosity of the protein gradually increases, stir it evenly), adjust the temperature to 55°C, add Alcalase protease (E / S=1.0%), keep the pH constant during the reaction. When the degree of hydrolysis DH=20%, adjust the pH to 4.0 to kill the enzyme, centrifuge at 3000r / min for 15min, and the supernatant obtained is the crude soybean peptide solution. The crude peptide solution is clarified and removed by microfiltration technology, and a microfiltration membrane (polysulfone membrane) with a pore size of 0.45μm is used. During the treatment process, ...

Embodiment 2

[0028] Low-temperature defatted soy flour is pickled twice. Add mass concentration 2g / LNa during pickling 2 SO 3 Solution, adjust pH 4.0, add pickling solution at 1:20 (w / v), temperature 50℃, washing time 15min, after pickling, centrifuge to remove the supernatant to obtain acid precipitation protein. After pickling the soy protein, add water at 1:15 (w / v), adjust the pH to 8.0 (in the process of adjusting to pH 8.0, the viscosity of the protein gradually increases, stir it well), adjust the temperature to 60°C, add Alcalase protease (E / S=3.0%), keep the pH constant during the reaction. When the degree of hydrolysis DH=20%, adjust the pH to 4.0 to kill the enzyme, centrifuge at 3000r / min for 15min, and the supernatant obtained is the crude soybean peptide solution. The crude peptide solution was clarified and removed by microfiltration technology. Using 0.10μm microfiltration membrane (polysulfone). During the treatment process, the microfiltration membrane takes 180 minutes...

Embodiment 3

[0030] Low-temperature defatted soy flour is pickled 3 times. Add mass concentration 2g / LNa during pickling 2 SO 3 Solution, adjust pH 5.0, add pickling solution at 1:20 (w / v), temperature 60℃, washing time 15min, after pickling, centrifuge to remove supernatant to obtain acid precipitation protein. After pickling soy protein, add water at 1:20 (w / v), adjust the pH to 8.0 (in the process of adjusting to pH 8.0, the viscosity of the protein gradually increases, stir it evenly), and add Alcalase protease (E / S= 2.0%), adjust the temperature to 60℃, and keep the pH constant during the reaction. When the degree of hydrolysis DH=20%, adjust the pH to 4.0 to kill the enzyme, centrifuge at 3000r / min for 15min, and the supernatant obtained is the crude soybean peptide solution. The crude peptide solution was clarified and impurity removed by microfiltration technology. The pore size of the microfiltration membrane used is 0.45μm (polysulfone). During the treatment process, the microf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com