Coal winning machine and mining height system thereof

A coal mining machine and mining height technology, which is applied in the field of coal mining machine and mining height system, can solve the problems of poor versatility, influence, error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a mining height system, which ensures that the operator can accurately know the height of the cutting drum in the driver's cab, ensures the safety of the operator, and at the same time has a significant impact on the structure of the shearer. The modification is less, which improves the versatility and reduces the cost. Another core of the present invention is to provide a coal shearer including the above-mentioned mining height system.

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

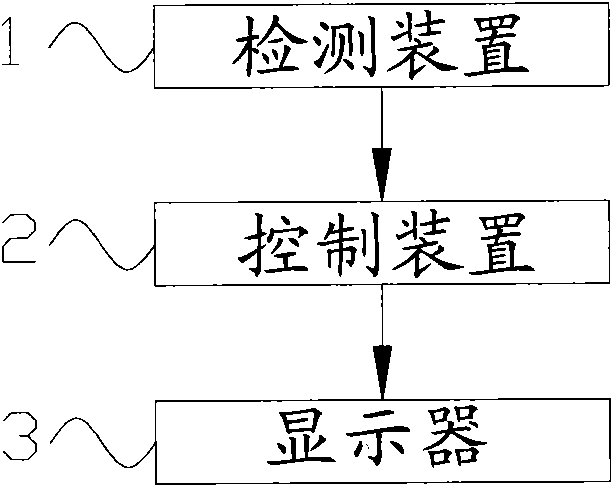

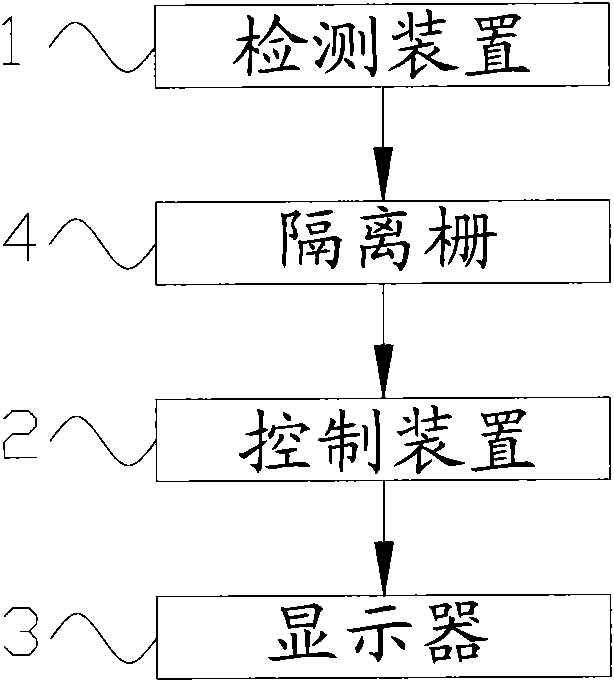

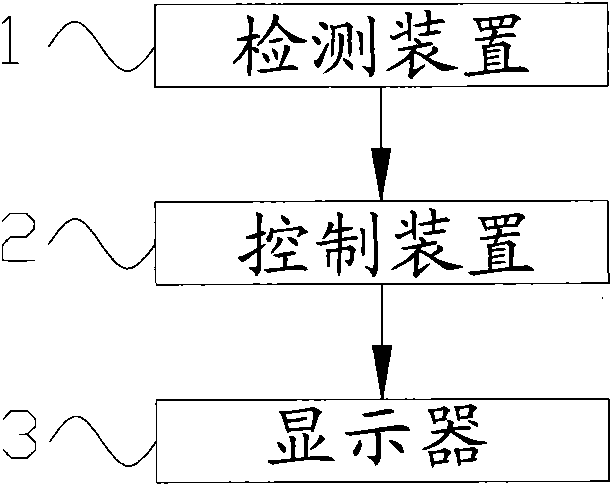

[0030] Please refer to figure 1 , figure 1 It is a structural block diagram of the mixer truck state monitoring system provided by the first specific embodiment of the present invention.

[0031] Such as figure 1 As shown, the mining height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com