Method for automatically monitoring roadway deformation in real time

A real-time monitoring and roadway technology, applied in the field of automatic real-time monitoring and roadway deformation, can solve problems such as non-uniform deformation, sudden deformation cannot be reflected in real time, measurement results are greatly affected by human factors, and data acquisition and data processing are not synchronized. , to achieve real-time continuous monitoring of the monitoring range, reduce input costs, and achieve good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

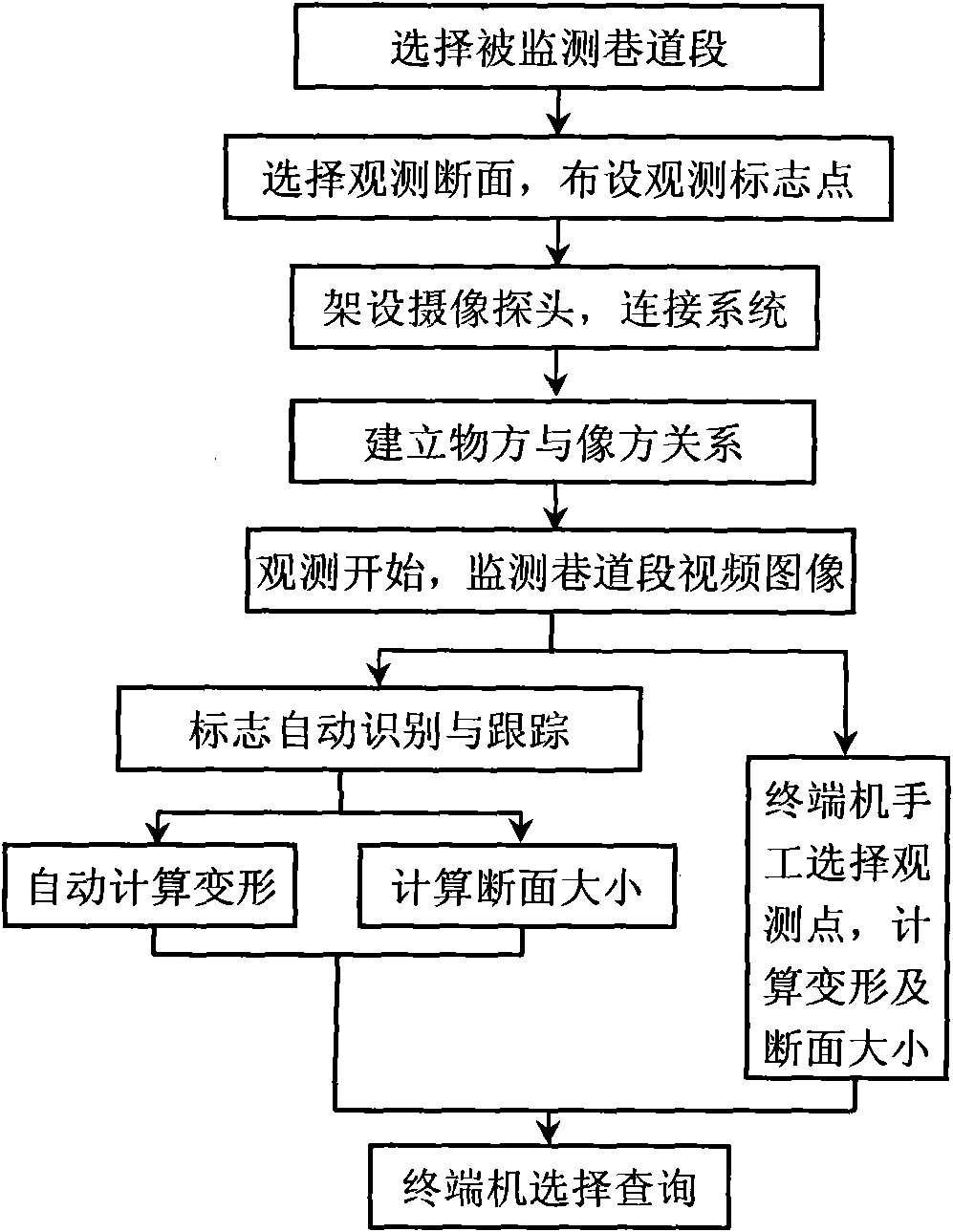

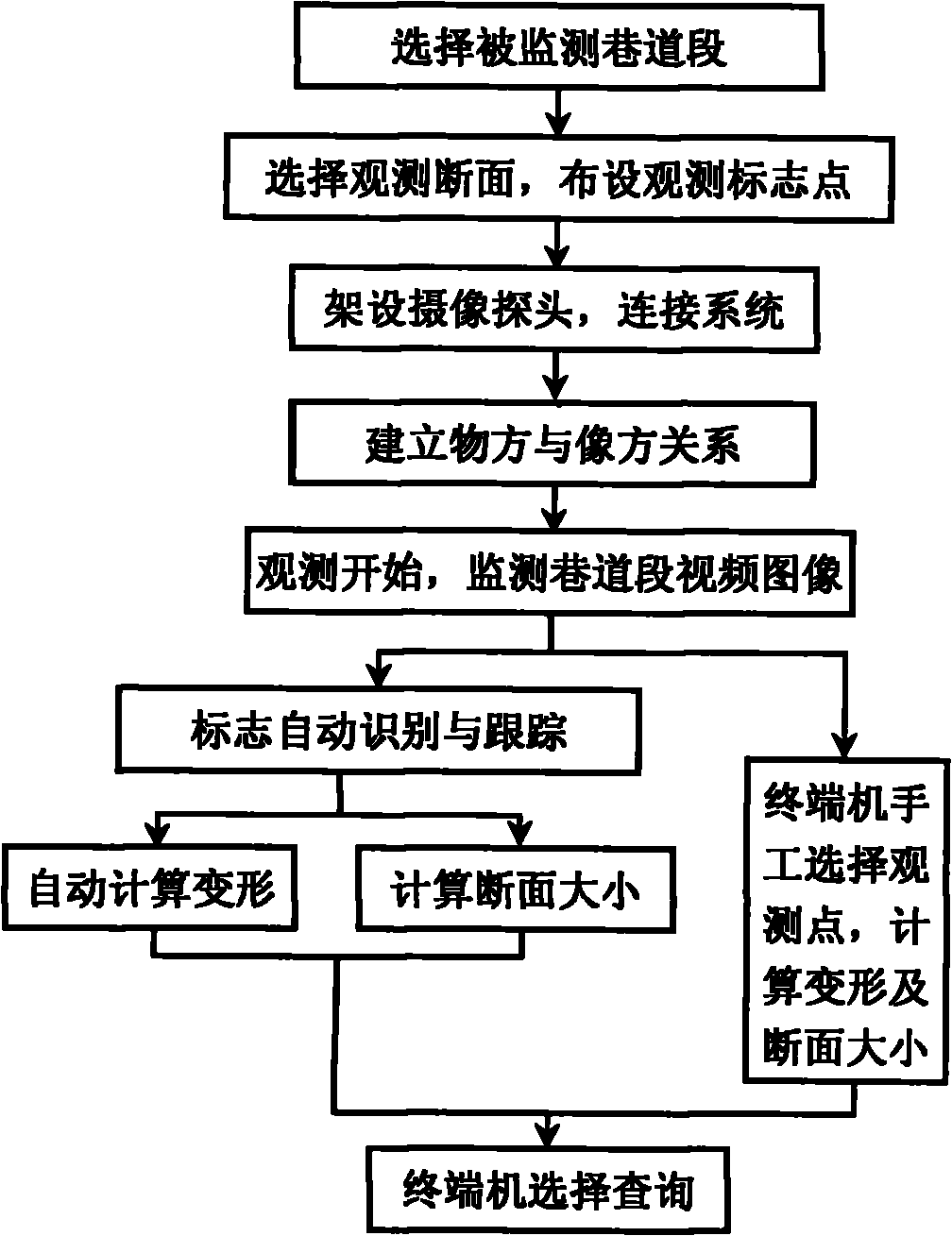

[0036] The automatic real-time monitoring method step of roadway deformation of the present invention is as follows:

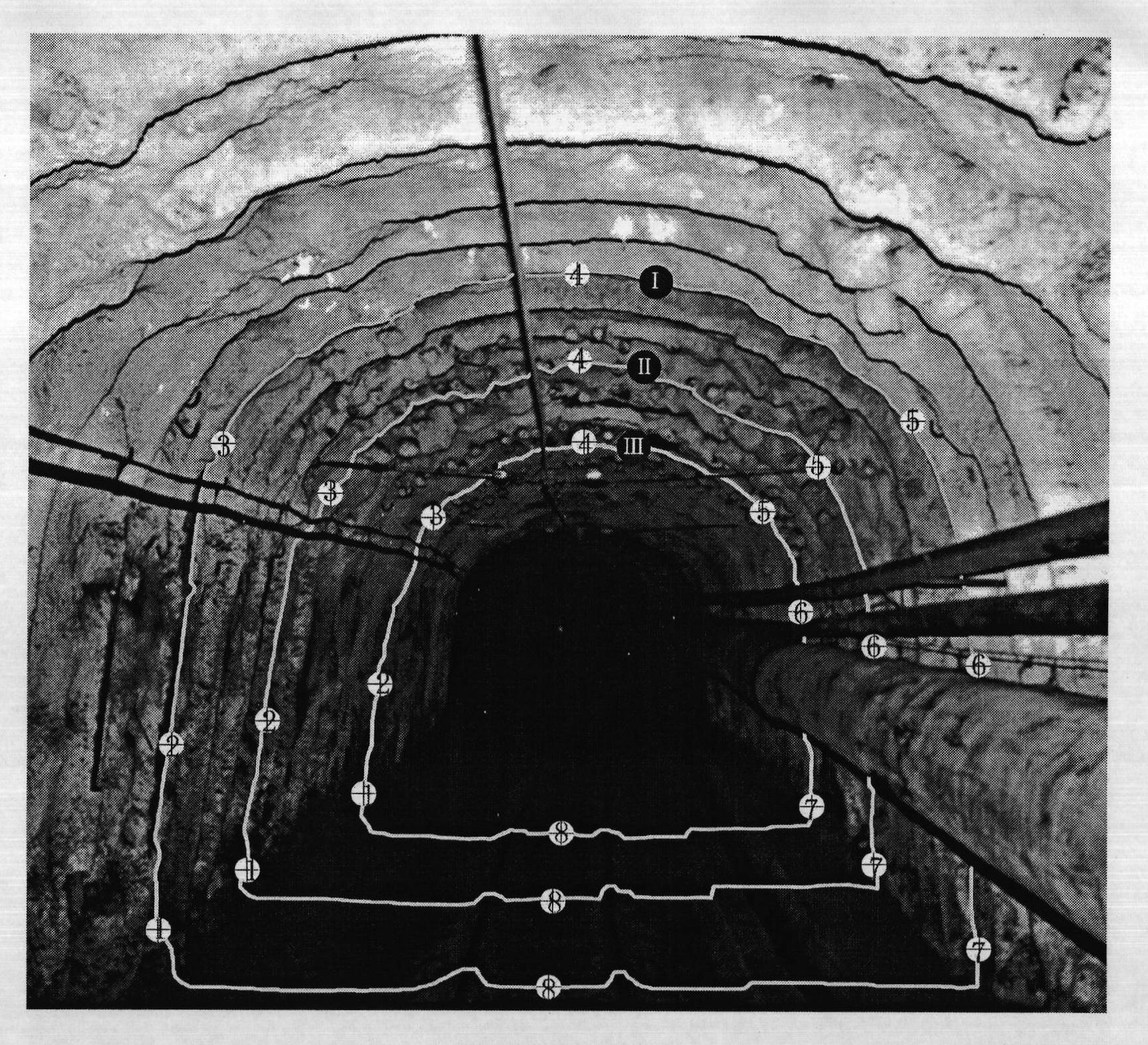

[0037] (1) First, select the roadway section to observe deformation according to the requirements, and select at least one section in the roadway section, such as figure 2 It is shown that three sections are selected in the roadway section. In order to facilitate identification from the image, section signs I, II, and III are respectively set on the three sections;

[0038] (2) Arrange multiple observation marker points on each section, and the observation marker points are survey point signboards with serial numbers of observation points that are easy to identify from the image, such as observation marker points ①, ②~⑧, etc.; the observation marker points are at least When there are four observation points, they are respectively located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com