Fixing method of magnet frame and basin bracket

A fixing method and magnetic frame technology, applied in the direction of fixing/tightening the diaphragm, can solve the problems of occupying the space of the pot frame, restricting the demand, improving, etc., to meet the needs of miniaturization, increase productivity, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

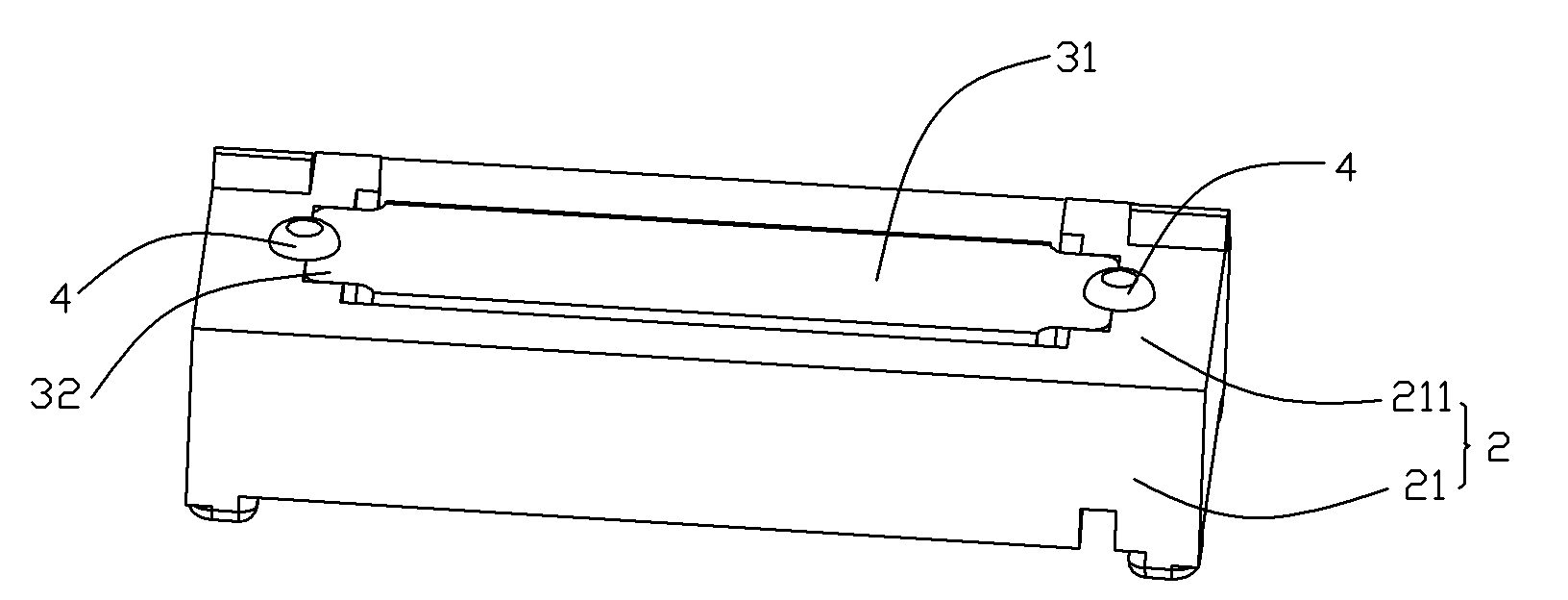

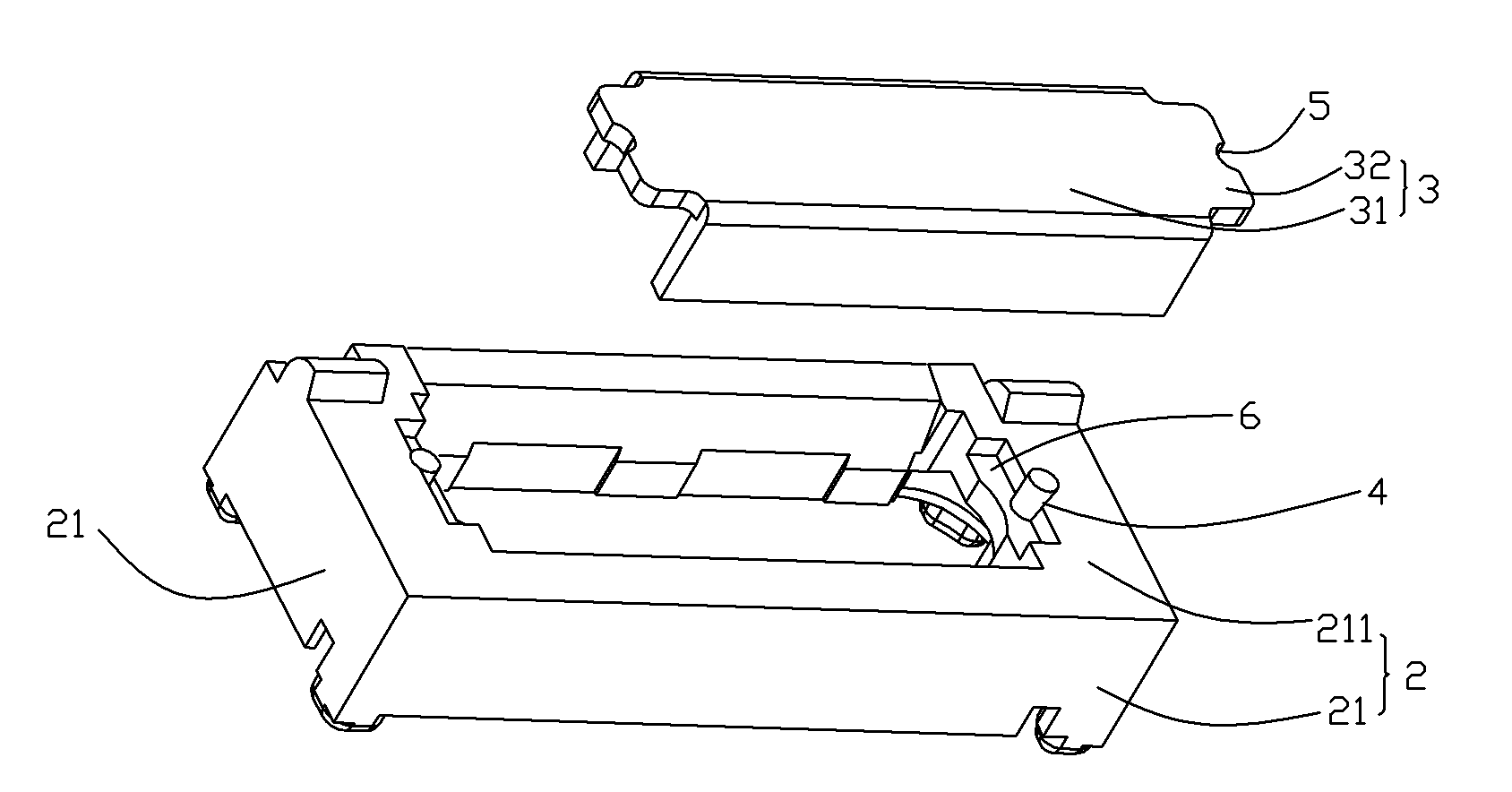

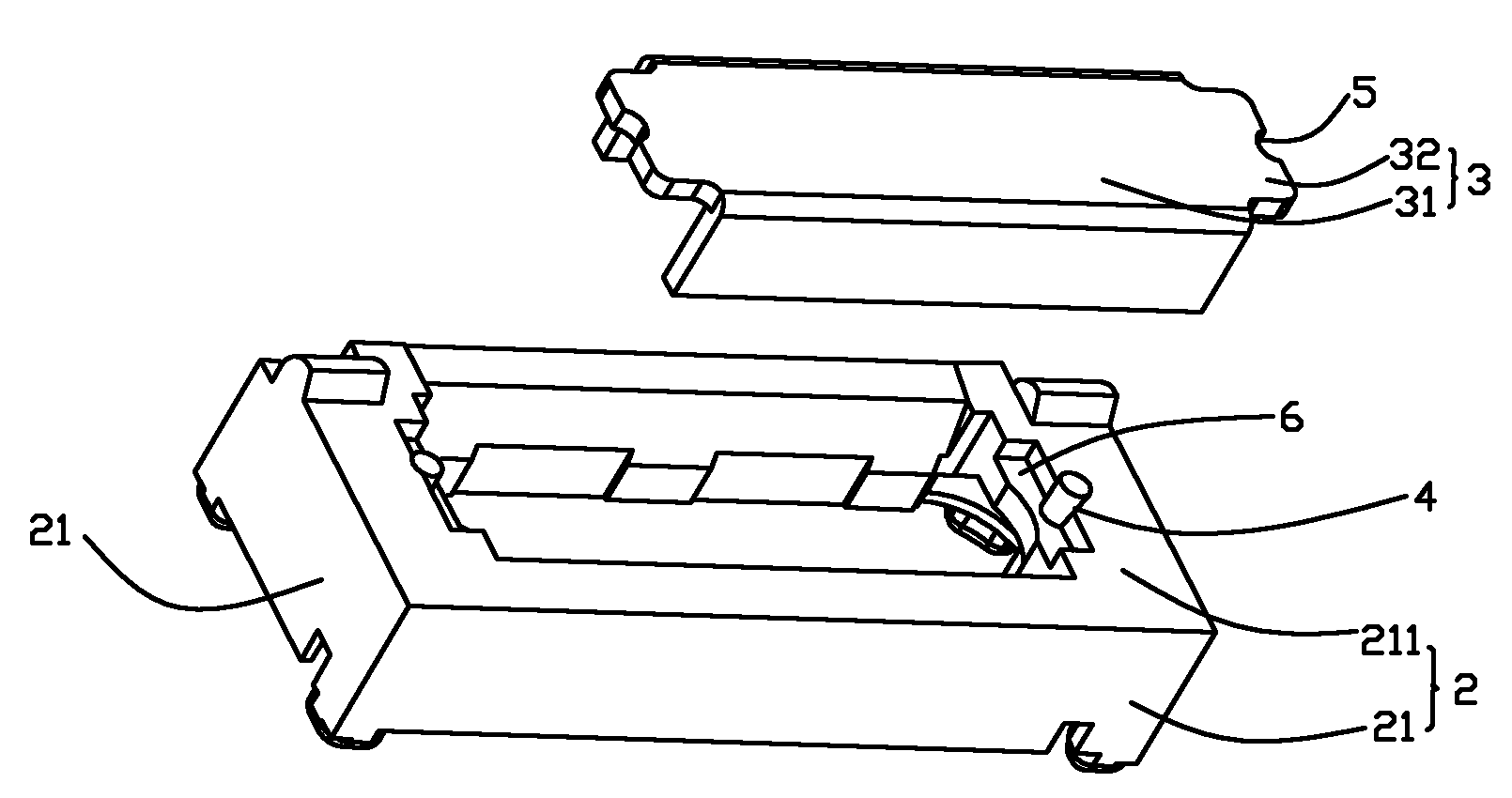

[0017] Such as Figure 1-2 As shown, a method for fixing a magnetic frame and a basin frame, the method includes the following steps:

[0018] A pot frame 2 is provided, and a plurality of positioning columns 4 are arranged on the pot frame 2;

[0019] A magnetic frame 3 is provided, and the magnetic frame 3 is provided with a plurality of positioning holes 5 which are connected with the positioning column 4;

[0020] Assemble the magnetic frame 3 to the basin frame 2, make the positioning hole 5 and the positioning column 4 fit and connect, then heat the positioning column 4 to partially melt and deform it, and press the melted and deformed part of the positioning column 4 against the positioning hole of the magnetic frame 3 5 and make the outer diameter of the melted and deformed part of the positioning post 4 larger than the diameter of the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com