Catalyst for removing NOx and preparation method thereof

A catalyst and main catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of polluting the atmospheric environment, increasing the operation and maintenance cost of denitration projects, and unstable catalyst activity and life. Good selectivity, improved anti-fly ash clogging ability, and stable denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

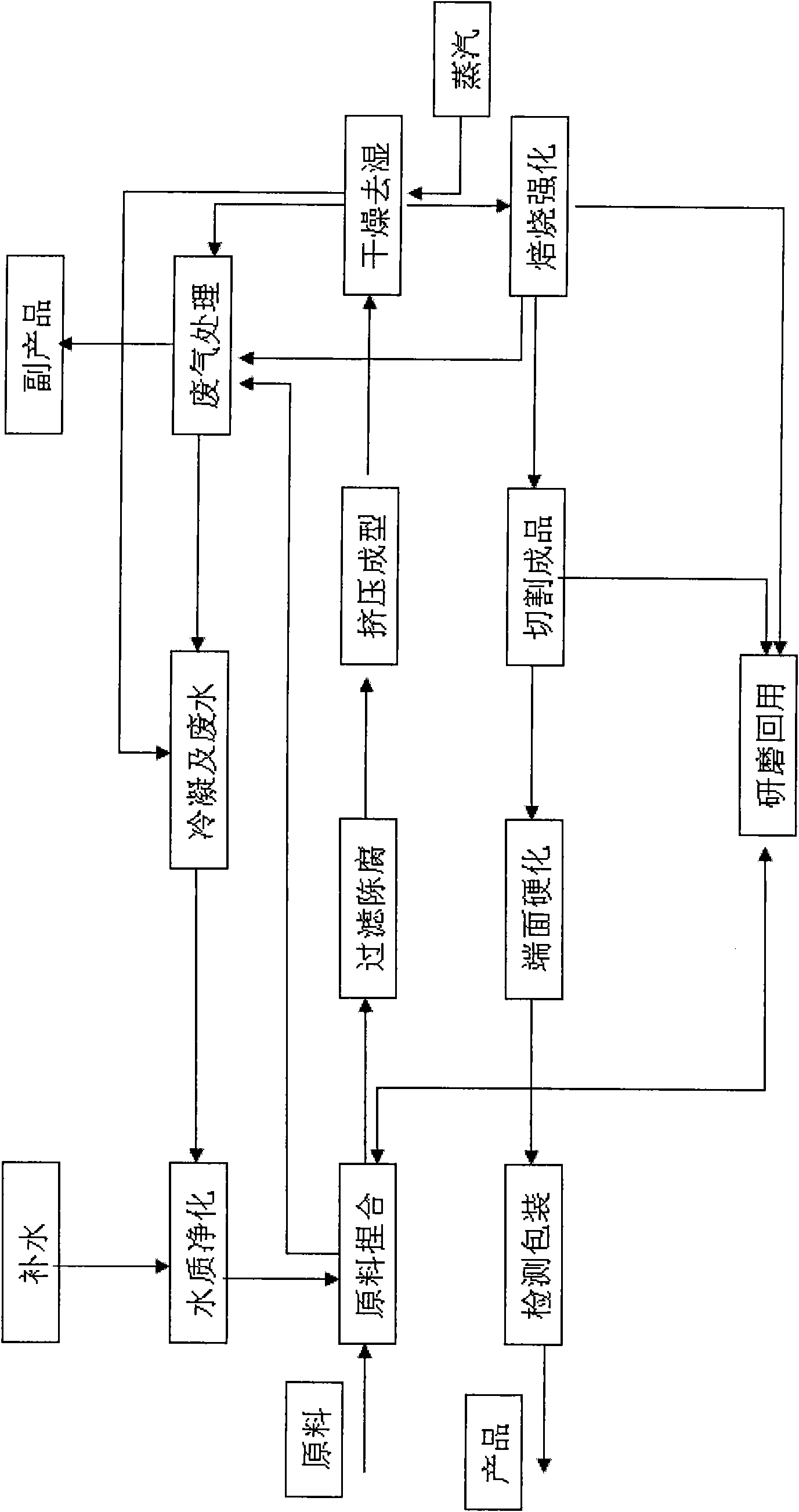

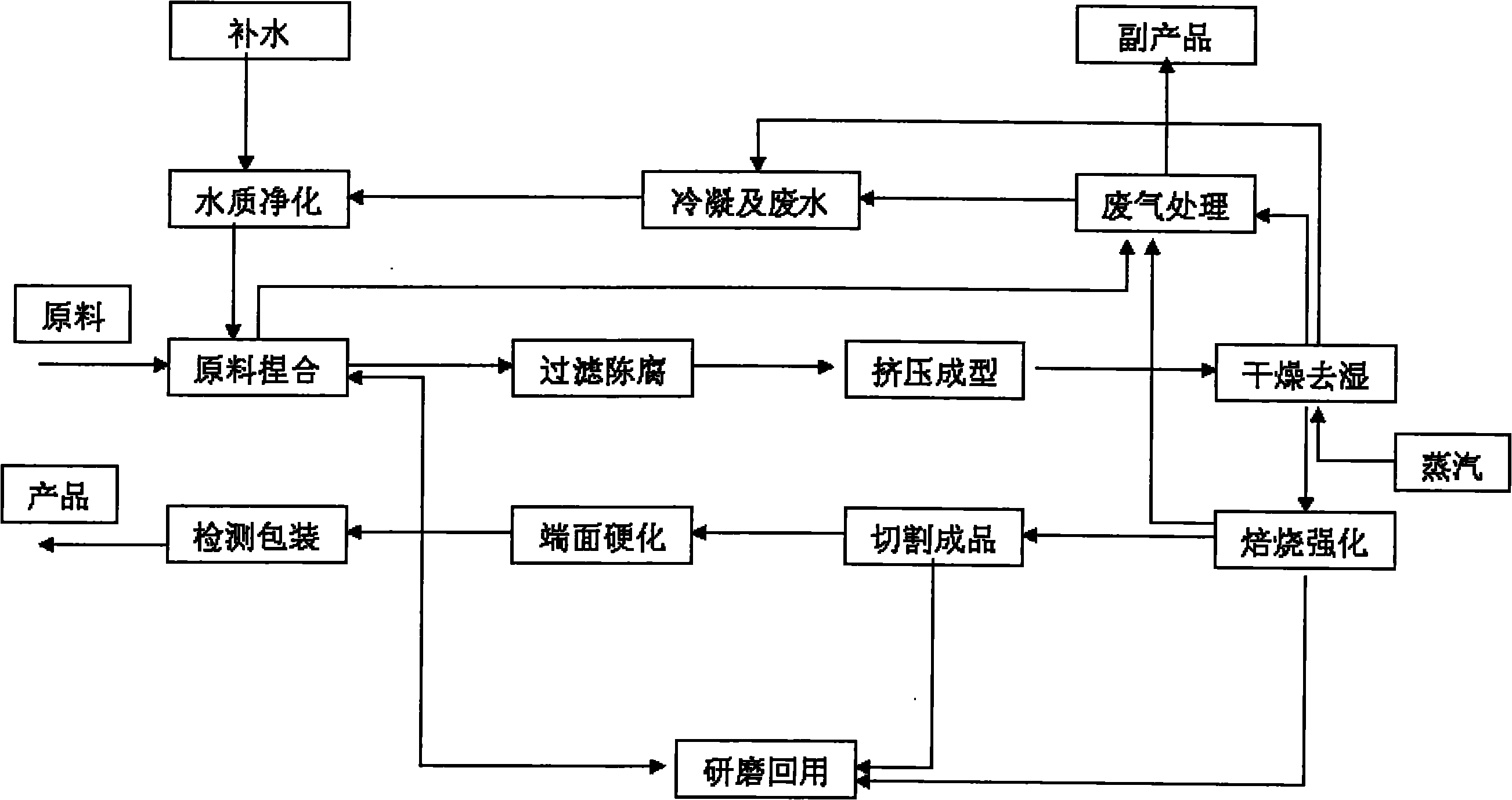

[0027] The following is combined with specific implementation examples and attached figure 1 The preparation method of catalyst of the present invention is described further:

[0028] 1. Kneading of raw materials

[0029] In the kneading stage, the carrier, active ingredients and various auxiliary materials are mixed and kneaded, so that the kneaded mixed material meets the extrusion requirements.

[0030] Add 610 kg of composite titanium dioxide to the mixing and kneading machine, then add 1.5 kg of stearic acid, 320 kg of deionized water, 55 kg of 15% ammonia water, 6.8 kg of 50% lactic acid, 35 kg of glass fiber, and 3 kg of wood pulp 1. 4 kg of ammonium metavanadate, fully stirred, the kneaded mixed material is packed into a container bag and sealed for one day.

[0031] Wherein, the main component of the composite titanium dioxide is TiO 2 、WO 3 and SiO 2 , and the weight percentage of tungsten oxide is not lower than 5%, and the weight percentage of silicon dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com