Multi-stage silencing structure for all terrain vehicle

A beach car and noise reduction technology, which is applied in the direction of noise reduction devices, engine components, machines/engines, etc., can solve the problems of easily blocked exhaust, exhaust resistance, air pollution, etc., to improve the purification and treatment effect, improve the noise reduction effect, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

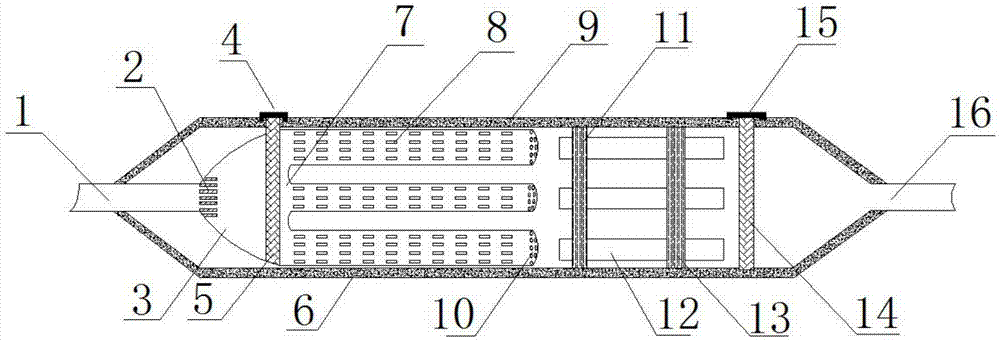

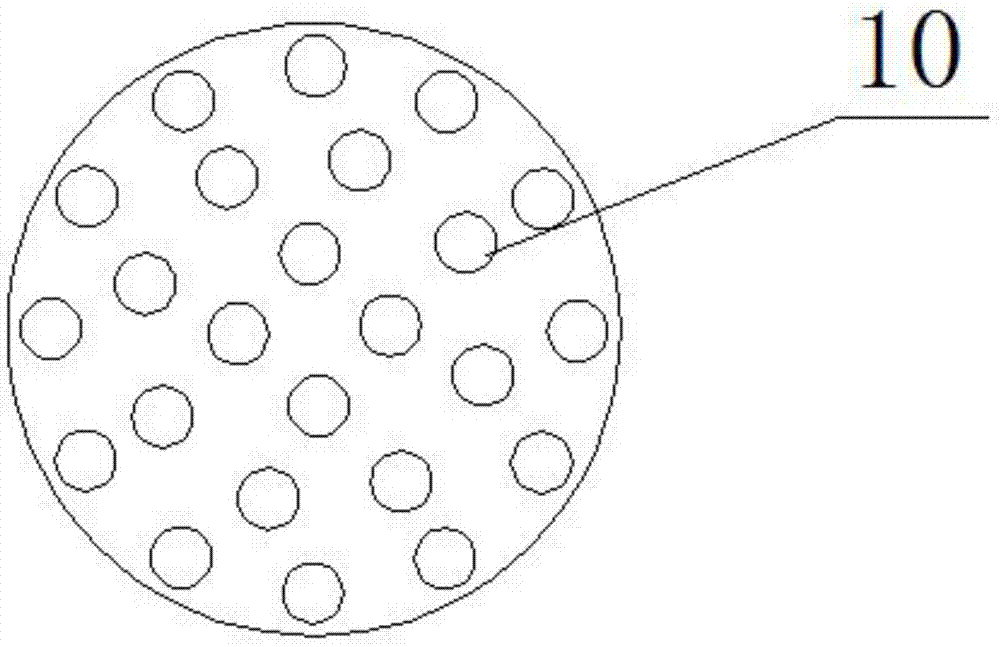

[0025] Specific embodiments of the present invention such as Figure 1-2 As shown, a multi-stage muffler structure for ATVs includes an intake pipe 1, an outlet pipe 16 and a muffler housing 6. The multistage muffler for ATVs also includes multiple buffer pipes, an airflow dispersion plate 2, and a first-stage Filter screen 5, secondary filter screen 14, primary sound-absorbing layer 11 and secondary sound-absorbing layer 13, many buffer pipes include arc-shaped ends 3 and some buffer pipes 8 arranged in arrays, flushing pipes are provided with multiple branches and arrays Arranged, it can evenly disperse the airflow and improve the effect of the muffler. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com