High temperature-resistant metal carrier

A metal carrier, high temperature resistant technology, applied in catalyst carriers, mechanical equipment, engine components, etc., can solve the problems of increasing engine fuel consumption, complex process, easy formation of air resistance in concave and convex parts, etc., to improve high temperature resistance performance, increase support points , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

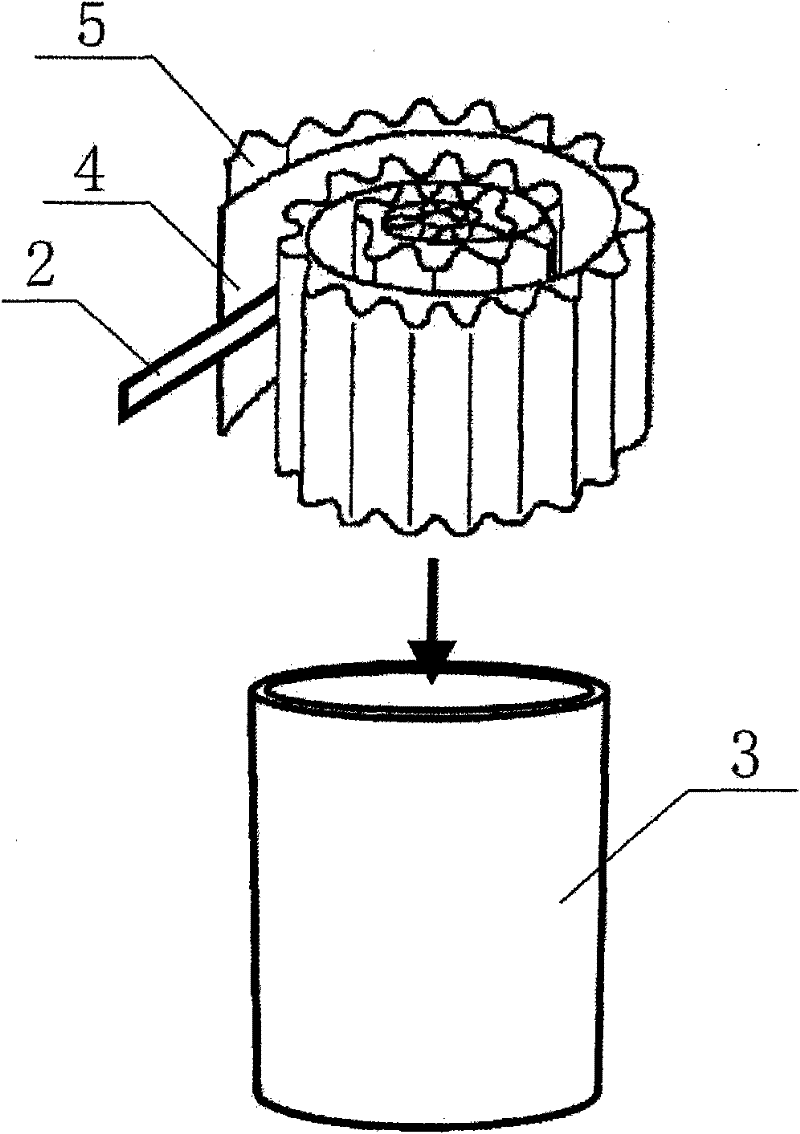

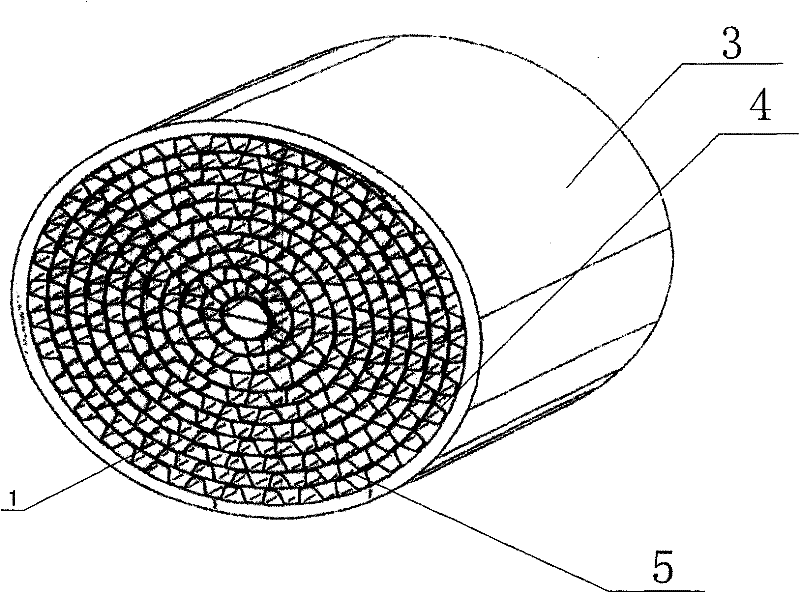

[0021] see Figure 4 ~ Figure 6 , the appearance structure of the present invention is as Figure 4 As shown, it is composed of an S-shaped inner core 1 and an outer shell 3. The S-shaped inner core 1 is made of overlapping flat sheets 4 and corrugated sheets 5 by the S-shaped rolling method, and the S-shaped inner core 1 is pressed into the The inner side of the cylindrical casing 3 coated with a brazing material is brazed.

[0022] For the diameter of the inner core 1 metal carrier, the flat sheet 4 and the corrugated sheet 5 that are not coated with solder 2 are alternately overlapped (see Figure 5 ) is placed in the S-shaped rolling machine (seeing the application number 200710148010.X patent application), and the S-shaped metal carrier inner core that has been rolled is pressed into the pre-coated brazing material (the brazing material and the described The solder 2 is the same) in the shell 3. Then put the completed metal carrier into a vacuum brazing furnace for b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com