Tundish with pouring box body

A technology of tundish and box, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc. It can solve the problems of short residence time of molten steel, secondary oxidation of molten steel, and affecting product quality, so as to reduce slag entrainment Chance, increase residence time, reduce the effect of liquid level fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

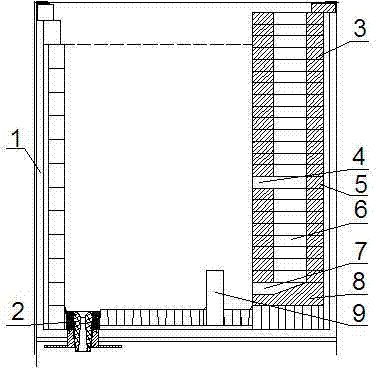

[0023] Such as figure 1 - figure 2 As shown, the package body 1 is circular, with a tundish spout 2 at the bottom, and a pouring box 10 on one side, and the casting box 10 is built by special-shaped bricks 1 , 2 special-shaped bricks 5 , and 3 special-shaped bricks Made, the pouring box 10 is provided with a pouring channel 6 in the middle, a molten steel outlet 7 is provided at the bottom, a flow steel hole 4 is provided in the middle, and a diversion dam 9 is provided at the front end of the molten steel outlet 7 at the bottom of the enclosure 1, and the diversion dam 9 is a The side is provided with leaking steel hole 11.

[0024] Such as image 3 - Figure 4 As shown, the special-shaped brick 3 is rectangular in shape, the front ends of the opposite sides are inclined inwardly, and a pouring channel 6 is provided in the middle.

[0025] Such as Figure 5 - Figure 6 As shown, the special-shaped brick 2 5 is rectangular in shape, and the front ends on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com