Method for preventing damaged seal of hydraulic oil cylinder from polluting hydraulic oil and filtering device

A technology of hydraulic oil filtration and hydraulic cylinder, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of seal damage and contamination of the hydraulic system, reduce oil pollution, avoid hydraulic pressure glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

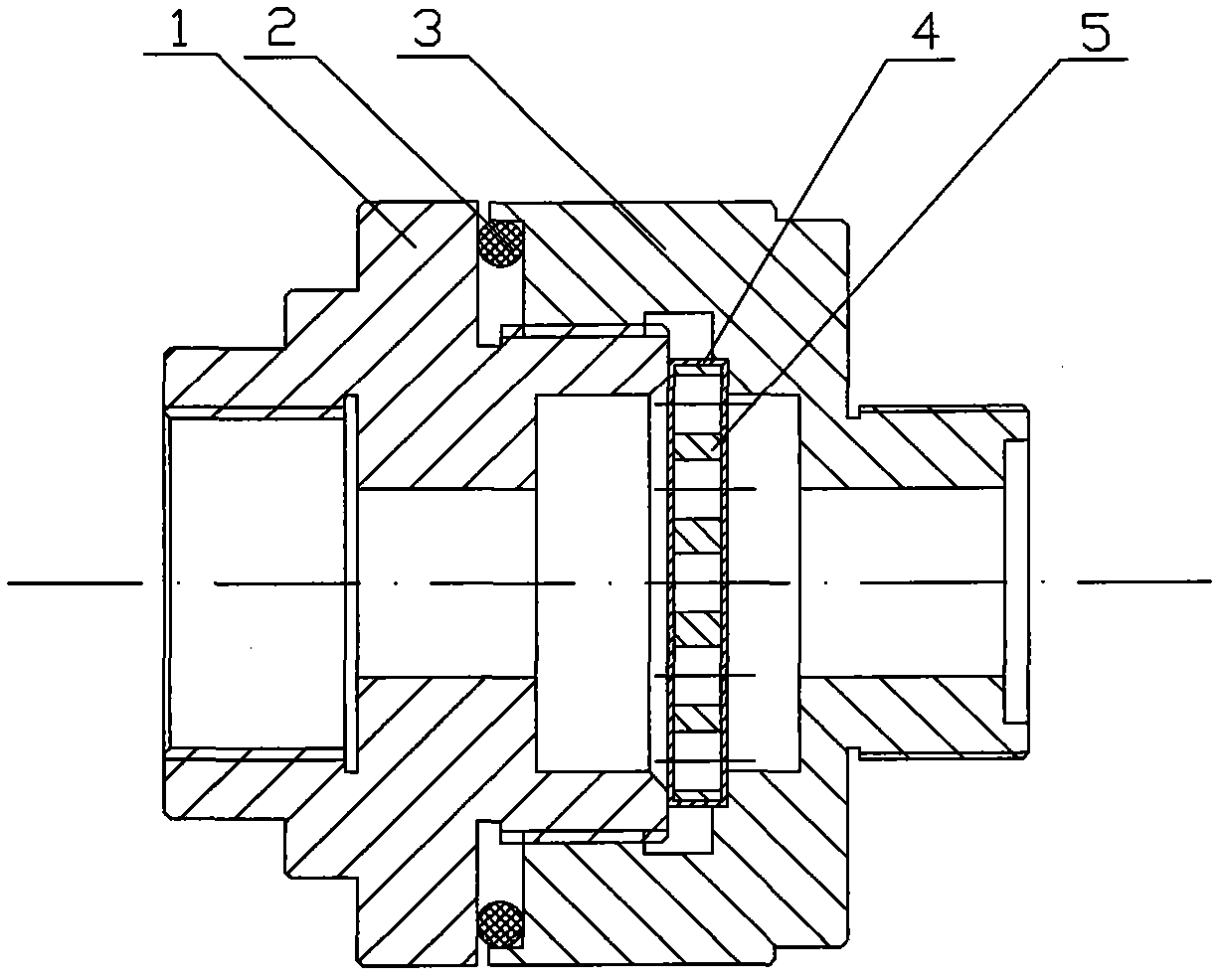

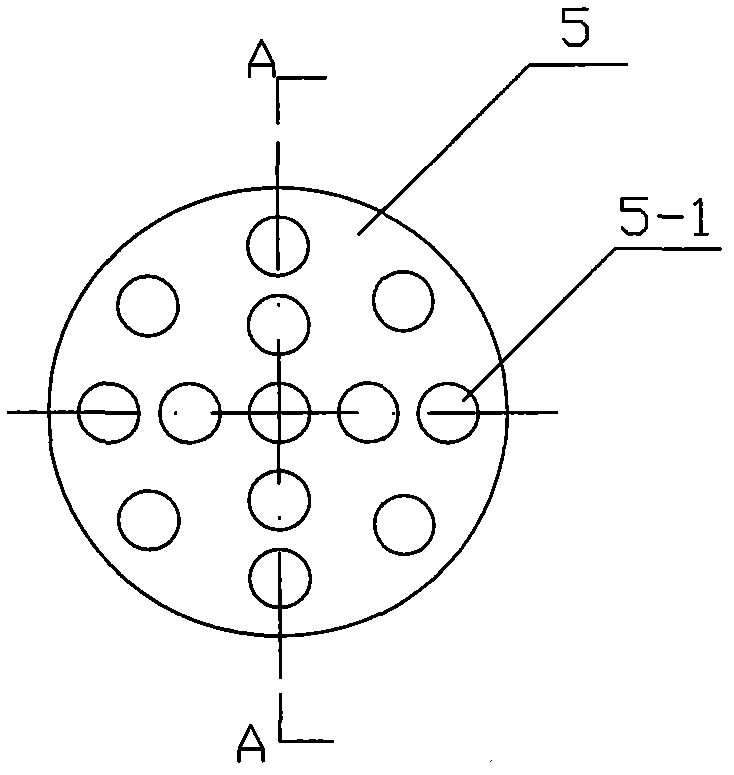

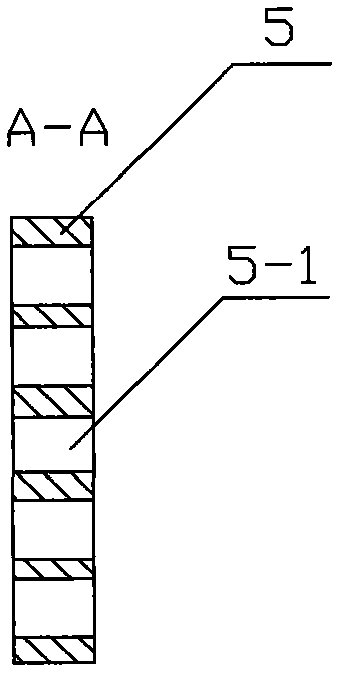

[0018] The invention discloses a method for removing hydraulic oil from hydraulic oil cylinder seal damage, which comprises installing a hydraulic oil filtering device on the oil port joints of chamber A and chamber B of the hydraulic oil cylinder respectively. During installation, the internal thread hole on the gland of a filtering device 8-1 is connected with the oil port joint 7-1 of the hydraulic cylinder 7A cavity, and the external thread on the filter cartridge is connected with the flexible pipe 6-1. The inner threaded hole on the gland of another filtering device 8-2 is connected with the oil port joint 7-2 of the hydraulic cylinder 7B cavity, and the external thread on the filter cartridge is connected with the flexible pipe 6-2. Through the hydraulic oil filter device, the damaged seal residue of the hydraulic cylinder is blocked at the cylinder port, so that it cannot enter the cylinder control valve, pressure and oil return pipe, and the hydraulic valve table and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com