Experimental device of free surface vortex forming and evolving mechanism

An experimental device and vortex technology, which is used in the research field of free surface flow in fluid mechanics, can solve problems such as undeclared patents, and achieve the effects of low cost, convenient and fast experimental observation and measurement, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

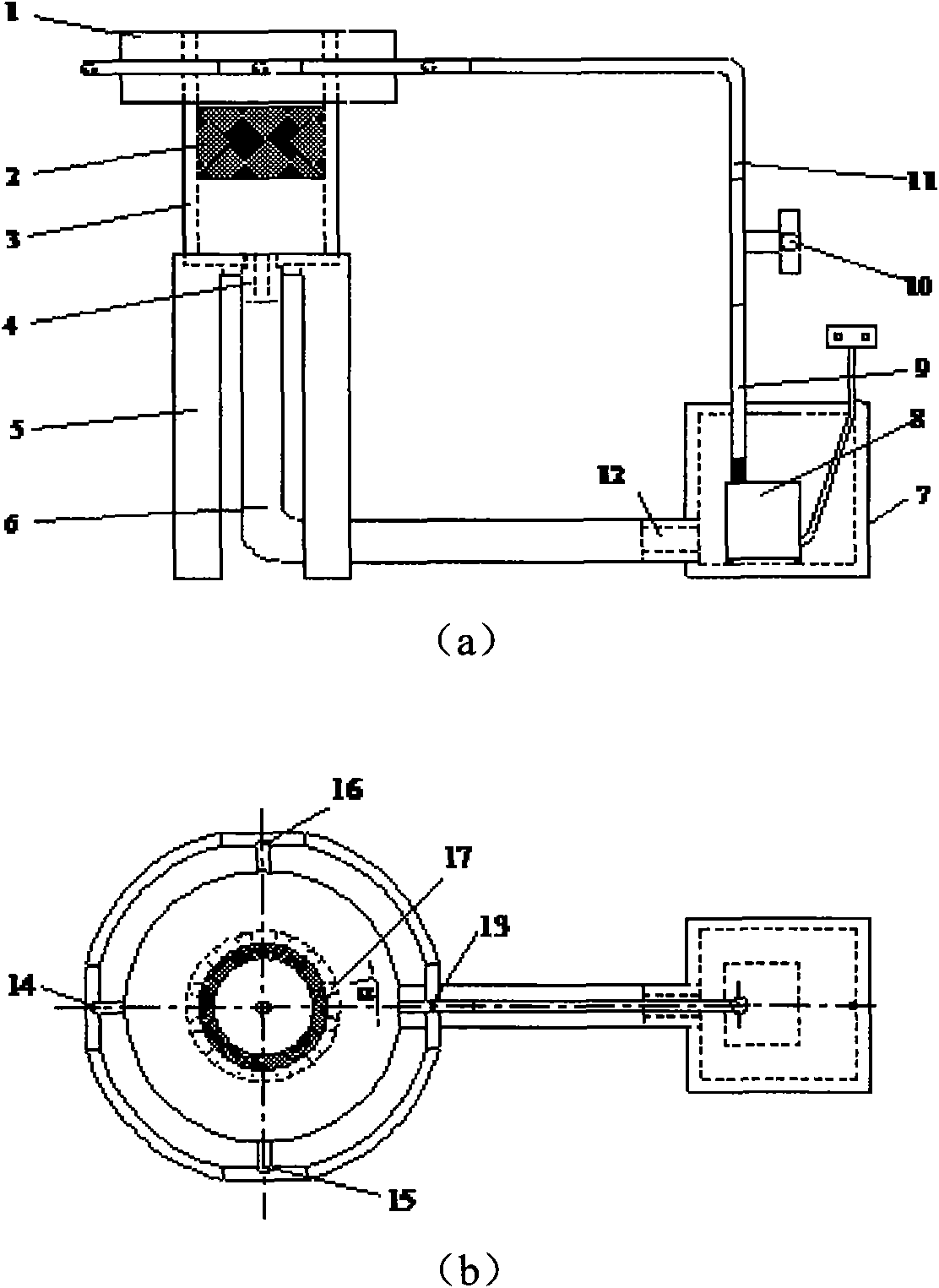

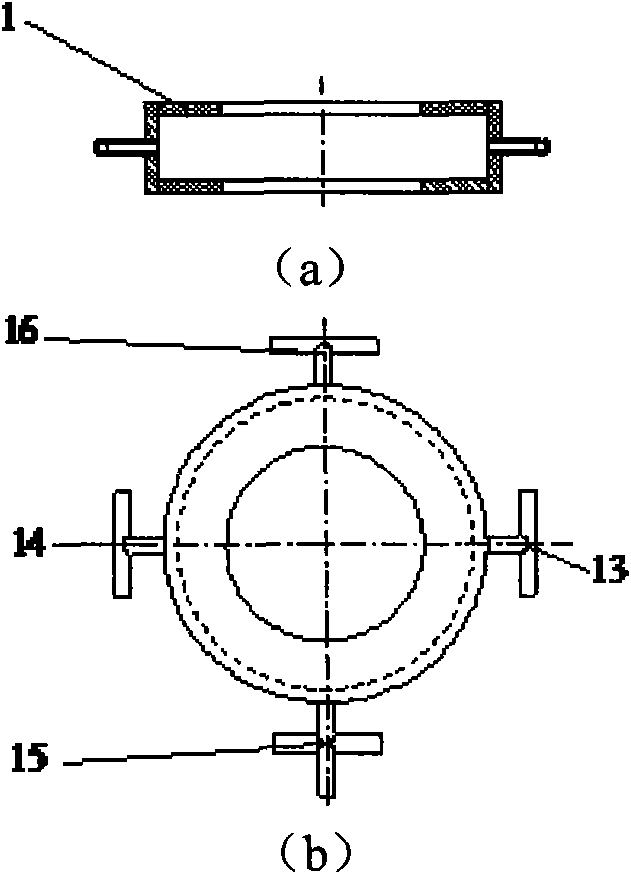

[0021] Embodiment one: with reference to attached figure 1 , the experimental device for the study of the free surface vortex formation and evolution mechanism, including a cylinder 3, a sealed water tank 7, a micropump 8, a flow regulating valve 10 and a water inlet buffer chamber 1, the upper part of the cylinder 3 is connected to the water inlet buffer chamber 1 are bonded together, and a sponge ring 2 is installed on the inner side of the cylinder wall of the cylinder 3 to stabilize the flow and increase the resistance. The water pipe joint 14 is connected through the thick pipeline 6; the micropump 8 is bonded to the bottom of the sealed water tank 7, and the water outlet of the micropump 8 is connected to the flow control valve 10 through the pipeline 9, and the flow control valve 10 is connected to the flow control valve 10 through the pipeline. 11 is connected to an inflow port 13 of the water inlet buffer chamber 1 through a four-way pipe joint, and the four-way pipe ...

Embodiment 2

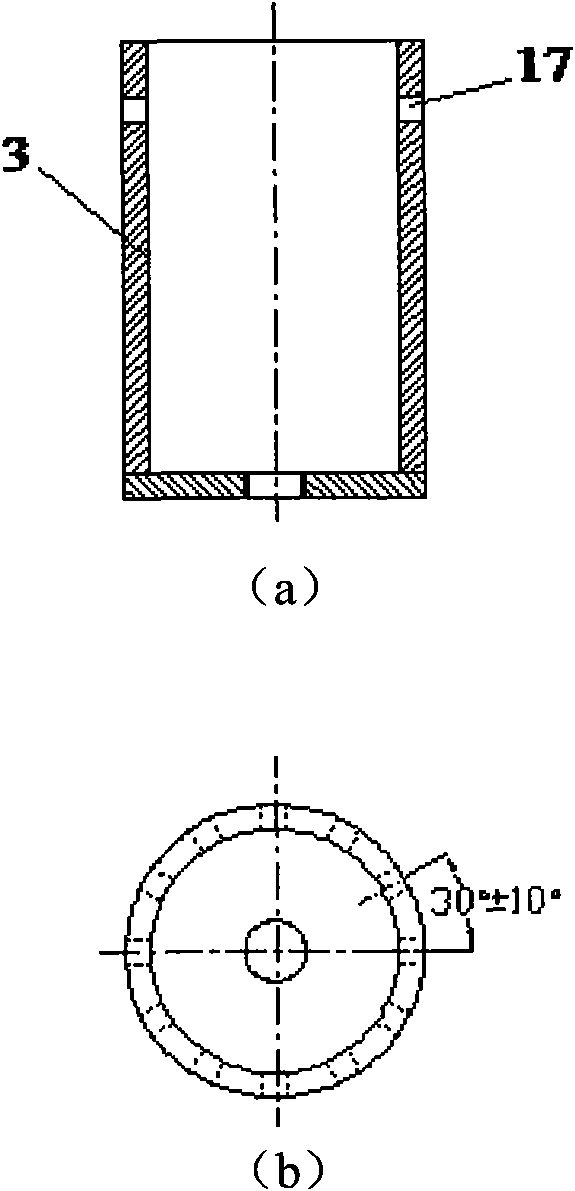

[0022] Embodiment two: this embodiment is basically the same as embodiment one, and the special features are as follows: figure 1 , figure 2 , image 3 with Figure 4 , the water inlet pipes 13, 14, 15, 16 uniformly distributed in the circumferential direction of the water inlet buffer chamber 1 and the inflow hole 17 on the upper part of the cylinder 3 are misaligned. The upper opening of the cylinder 3 communicates with the outside atmosphere, and the bottom is provided with an internal thread to be screwed with the outlet pipe joint 4 . The cylinder 3 is supported by a support frame 5 , and the top of the support frame 5 has a circular groove to be arranged with the cylinder 3 . The outlet pipe joint 4 is connected to the water outlet of the cylinder 3 through a sealing ring to ensure no leakage; the outlet pipe joint 4 is a group except the inner aperture (d 2 ), other structural dimensions (H, D, d 1 ) consistent series of fittings. Except the micropump 8, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com