One-dimensional light-condensing drawing-formed groove-type parabolic mirror and manufacturing method thereof

A manufacturing method and technology for parabolic mirrors, which are applied to condensers, optics, mirrors, etc., can solve the problems of complex bracket structure, poor bracket rigidity, unstable quality, etc., and achieve the effects of high reflectivity, easy cleaning, and simple installation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

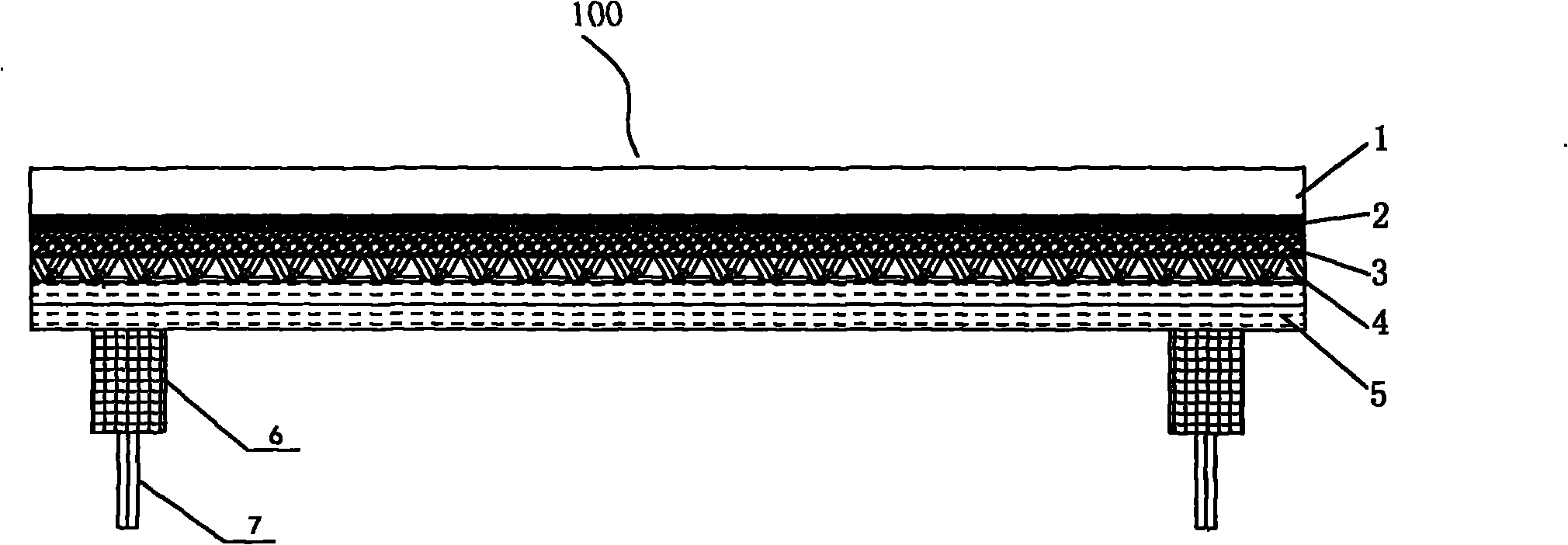

[0025] Such as figure 1 As shown, the high-reflection strengthened composite glass mirror 100 is a composite structure, and its composite layer structure is as follows: it is sequentially composed of high-transmittance flat strengthened glass 1 (generally, thinner and large-area glass is used), a silver-plated reflective layer 2, Protective layer 3 (which can be metal coatings such as copper and nickel, or resin and fluorocarbon paint), interlayer 4 (PVB, EVA interlayer protective layer), and back plate layer 5. The back plate layer 5 can be made of glass fiber reinforced plastics Board FRP; also PET, TPE, TPT and other back film, tempered glass, etc.

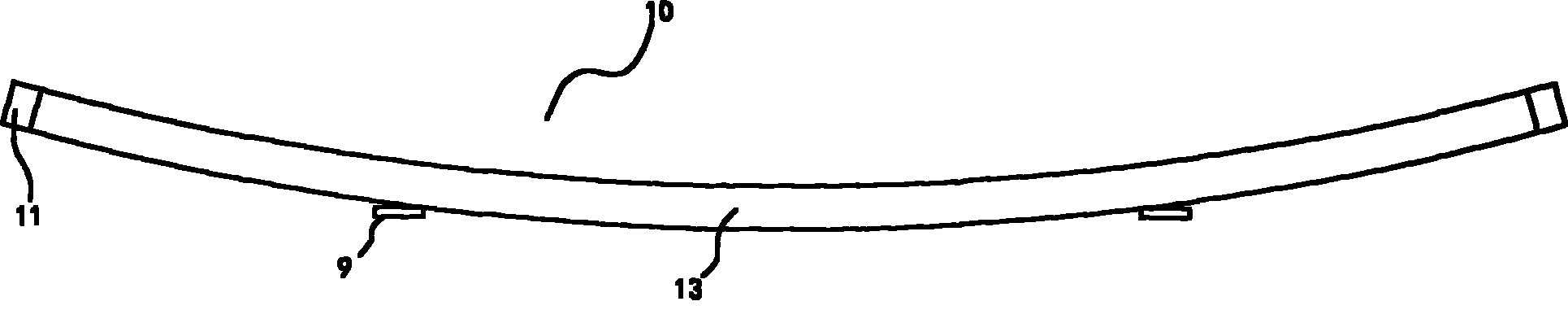

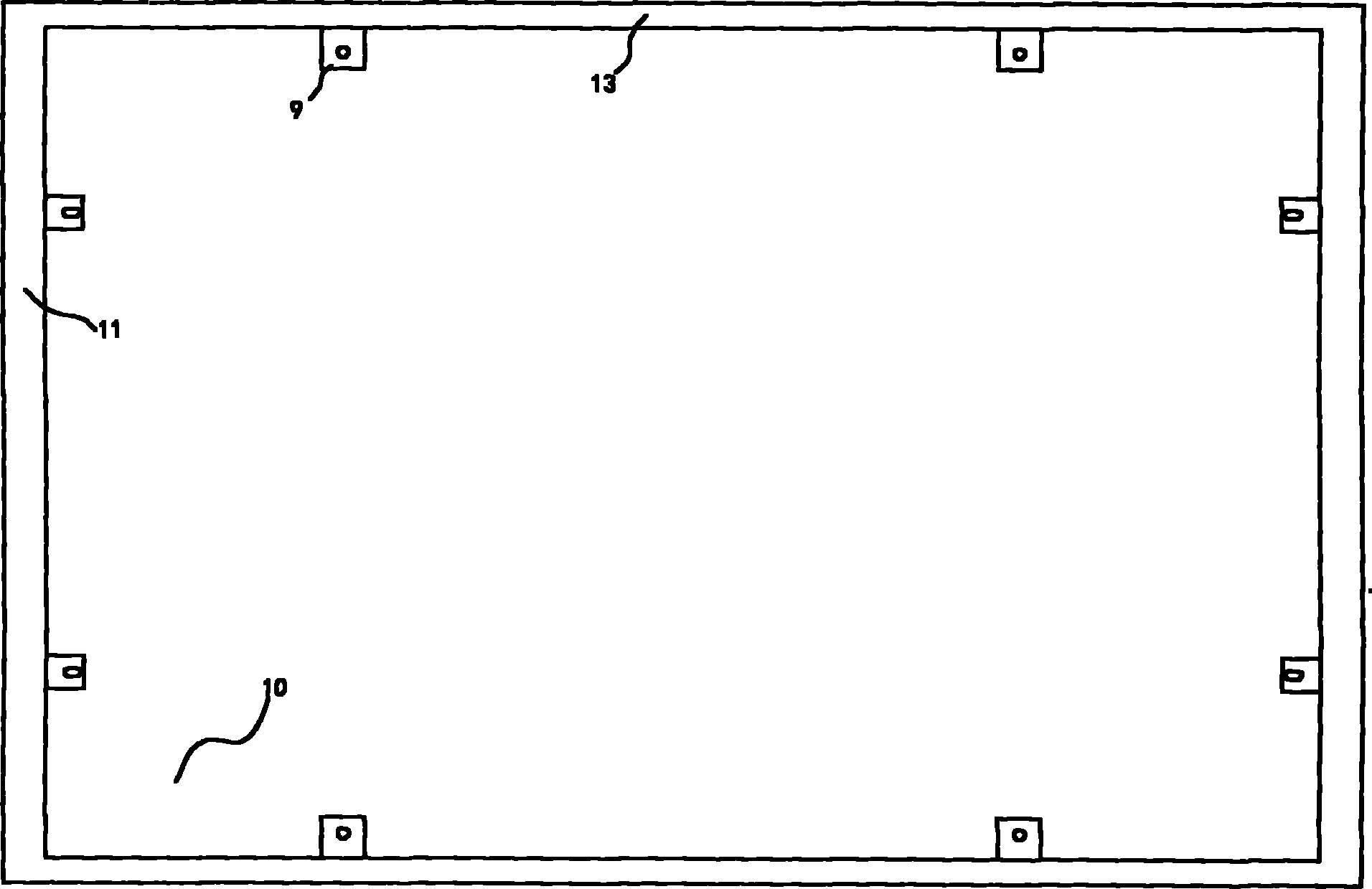

[0026] In addition, a pulling device is fixed (adhesively may be used) on the back plate layer 5 . see figure 2 , 3 , 4. The pulling device includes: a connecting square tube 6 bonded to the surface of the protective backboard layer 5, a pulling screw 7 installed on the connecting square tube 6 and an adjusting nut 12 coope...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap