An electrocoagulation cell

An electrocoagulation and electrode technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve problems such as poor electrical contact, waste of space, and adverse effects. Achieve the effect of relative voltage drop and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

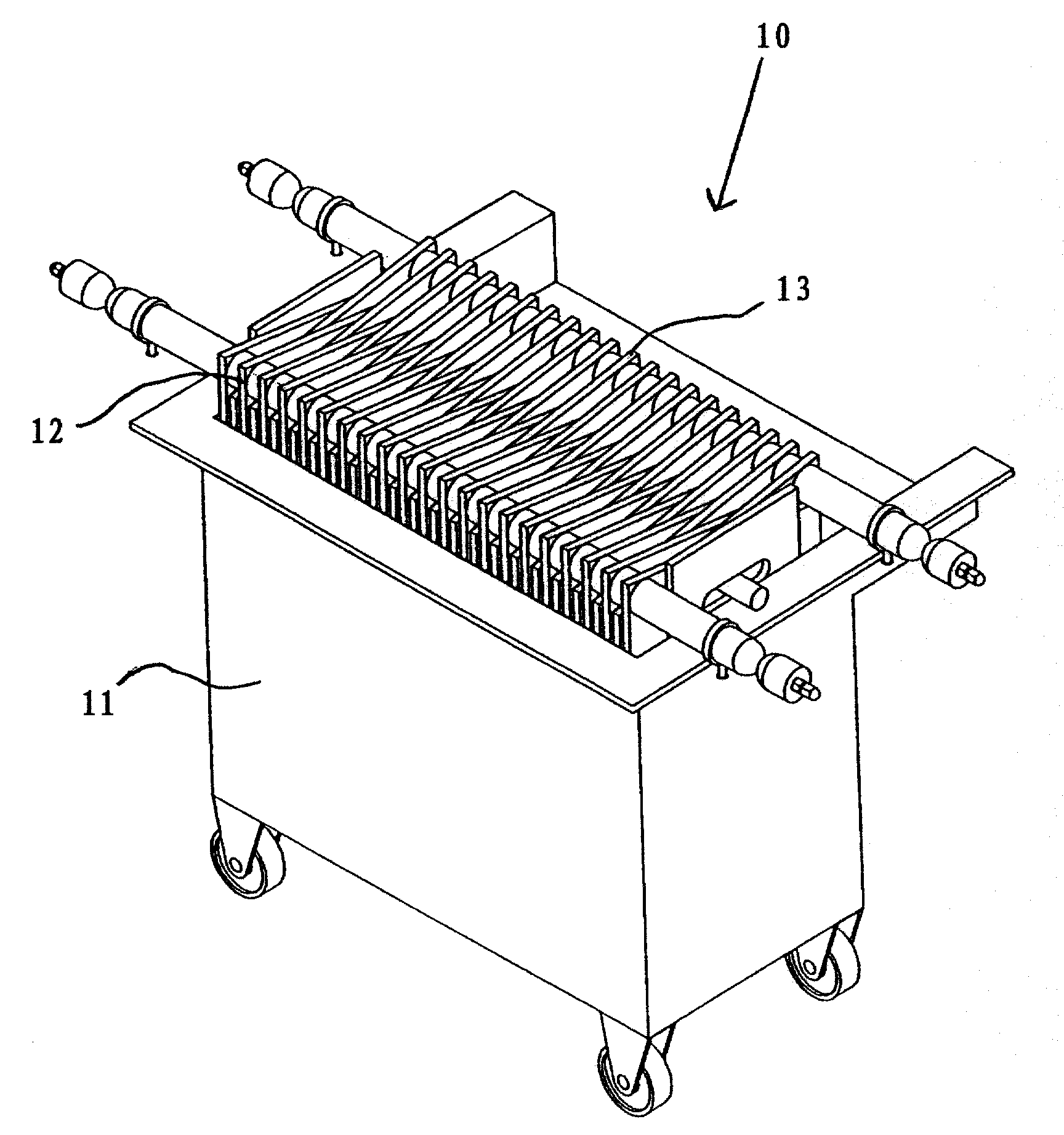

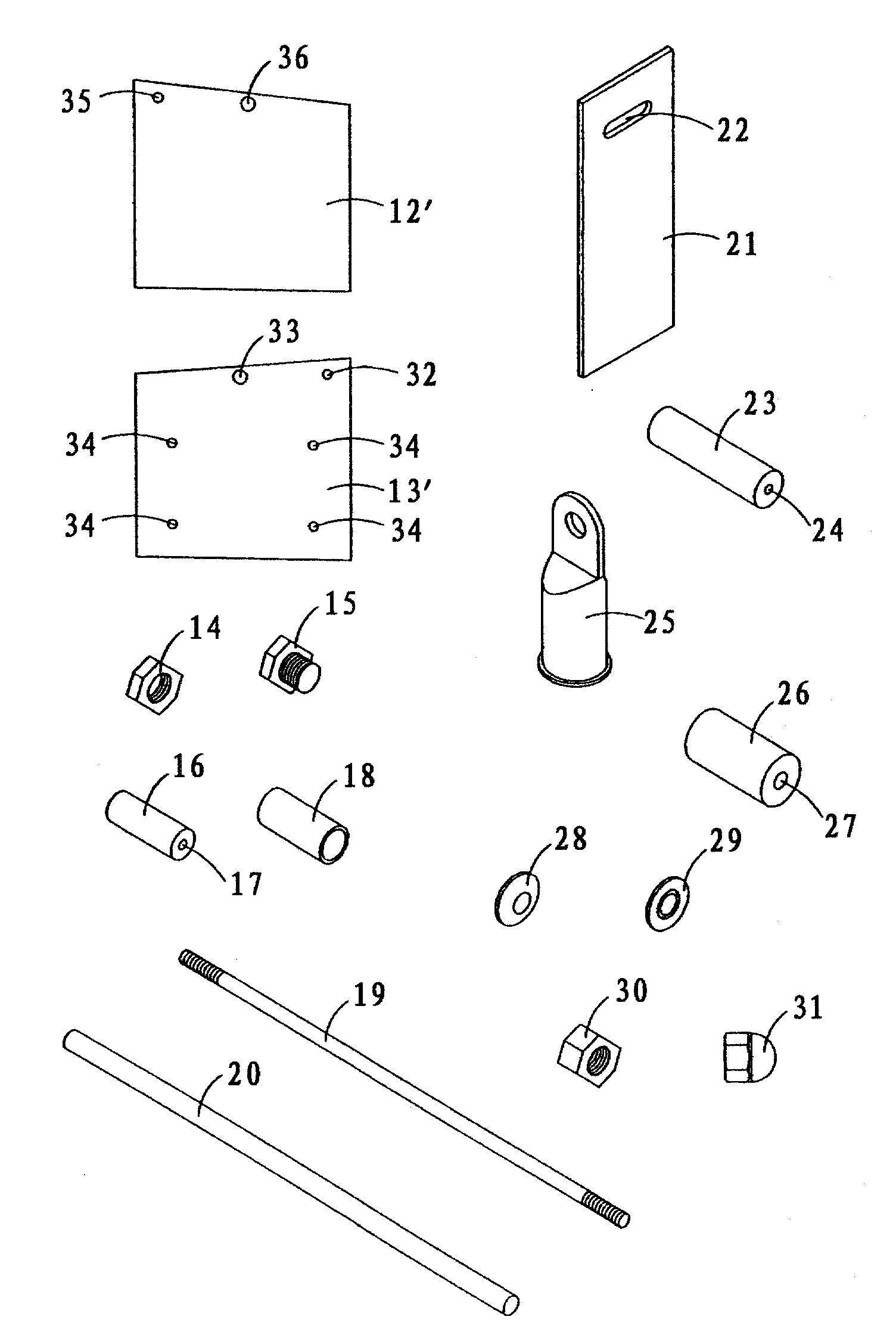

[0117] Assembled as described above with a first group of twenty-one aluminum electrodes 12' and a second group of twenty aluminum electrodes 13', such as figure 1 The electrocoagulation unit 10 is shown, and the electrocoagulation unit 10 is connected to the spraying system 45 . The electrocoagulation cell 10 is connected to a rectifier 56 . The positive terminal of the rectifier 56 is connected to the electrical connector 25 provided at either end of the first connecting rod 19 and the negative terminal of the rectifier 56 is connected to the electrical connector 25 provided at either end of the second connecting rod 19 .

[0118] Let 800 amperes flow into the electrocoagulation unit 10, where 400 amperes pass through the aluminum feed sleeve 23 provided at one end of the first connecting rod 19 and 400 amperes pass through the other end of the first connecting rod 19 The aluminum feed bushing 23 of the electrode flows in such that each electrode 12' disposed on the first c...

Embodiment 2

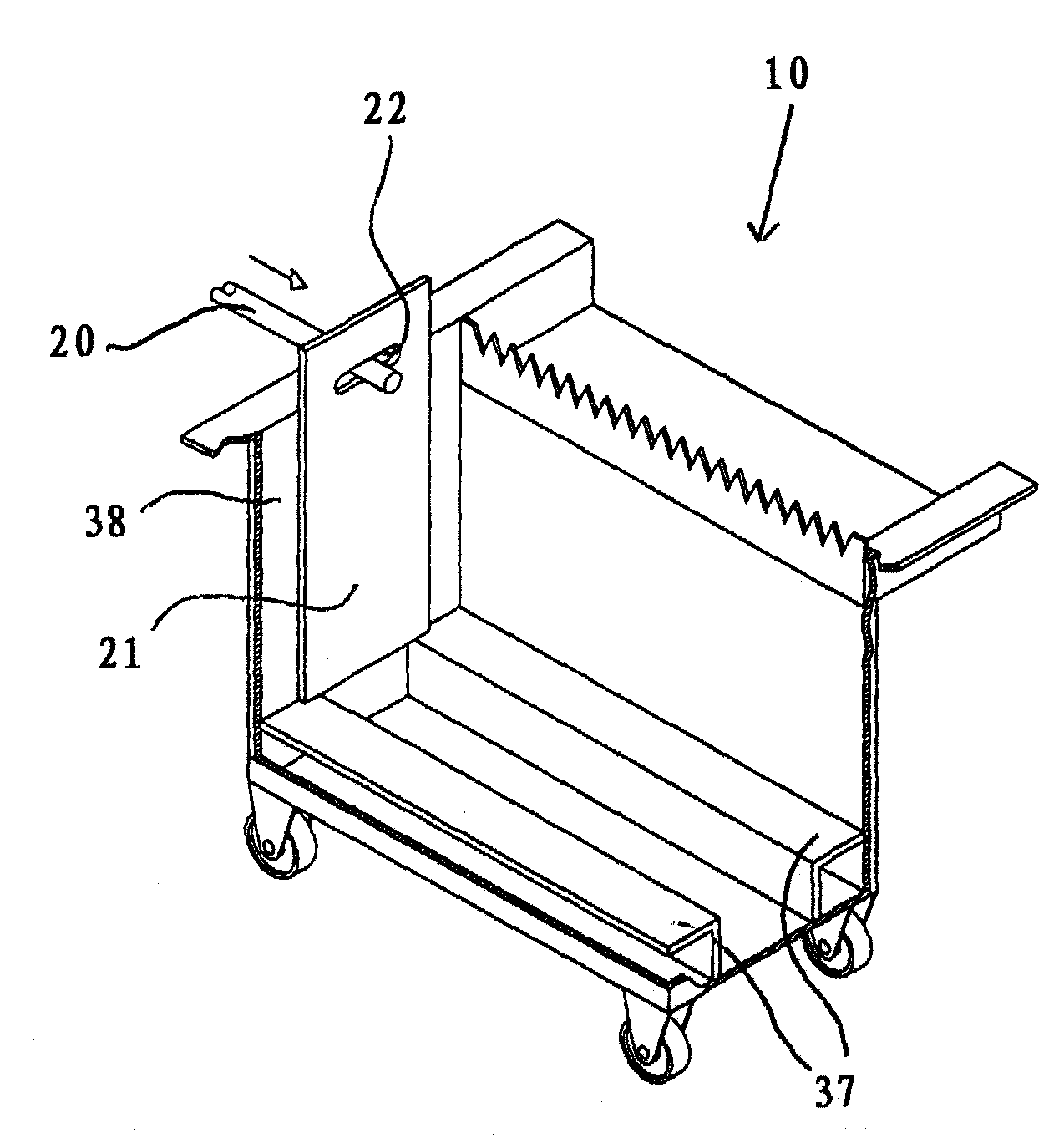

[0123] Four electrocoagulation cells 10 - each having a first set of twenty-one aluminum electrodes 12' and a second set of twenty aluminum electrodes 13' - were assembled as described above and connected to the spray System 45 and with Figure 8 In the same manner as the electrocoagulation unit 10 in the electric coagulation unit, it is arranged in the form of electrical series connection and liquid parallel connection.

[0124] The positive terminal of the rectifier 56 is connected to the electrical connection 25 provided at either end of the connecting rod 19 of the first electrocoagulation cell 10 . Connect the electrical connection piece 25 provided at any end of the other connecting rod 19 of the first electrocoagulation unit to the electrical connection device 25 provided at any end of the connecting rod 19 of the second electrocoagulation unit 10 . The second electrocoagulation unit 10 is connected to the third electrocoagulation unit 10, and the third electrocoagulat...

Embodiment 3

[0131] Four electrocoagulation cells 10 - each having a first set of twenty-one aluminum electrodes 12' and a second set of twenty aluminum electrodes 13' - were assembled as described above and connected to the spray System 45 and with Figure 8 In the same manner as the electrocoagulation unit 10 in the electric coagulation unit, it is arranged in the form of electrical series connection and liquid parallel connection. The amount of current flowing into the electrocoagulation cell 10 varies between 400-450 amperes due to variations in the flow rate of liquid flowing into the cell 10 . Electric current flows into and through the electrocoagulation cell 10 in the same manner as described in Example 1 and Example 2.

[0132] 36-39m from glass cutting operations 3 / hour of effluent is pumped through the electrocoagulation cell 10 . The effluent contained 800-1000mg / litre of suspended glass slag and 40-60mg / litre of dissolved lead. The electrocoagulation unit 10 worked contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com