A column mobile machine tool light machine

A mobile, column technology, applied in the direction of metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of poor flexibility of machine tool guide rails, friction loss errors, difficult to observe, etc., to achieve controllability and stability Poor performance, reduced swing, and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

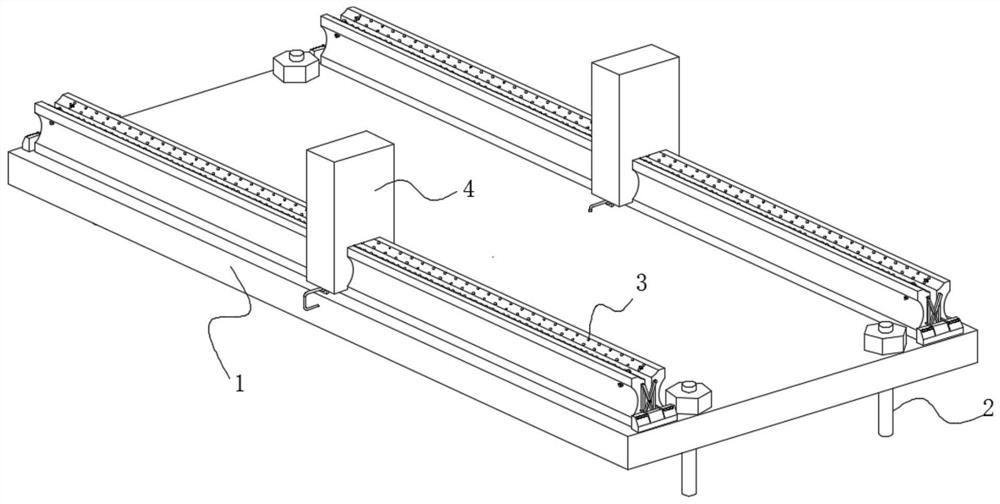

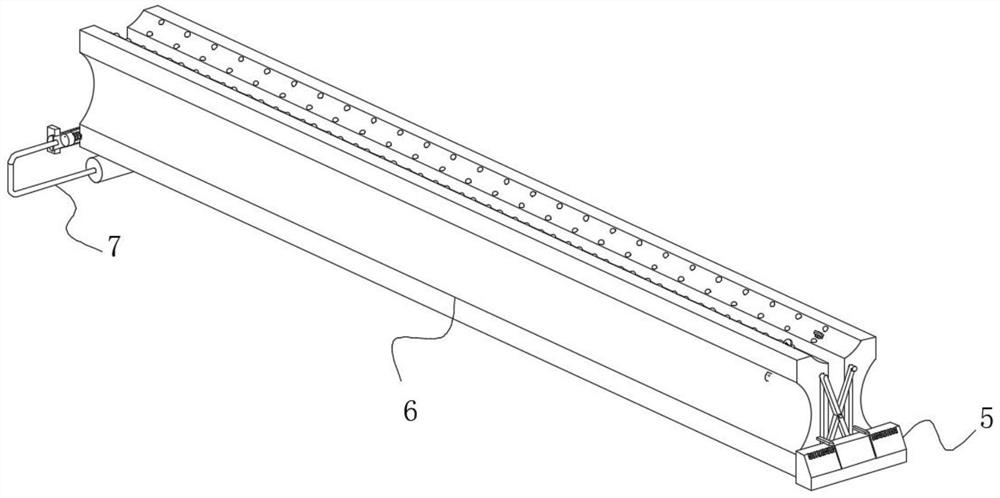

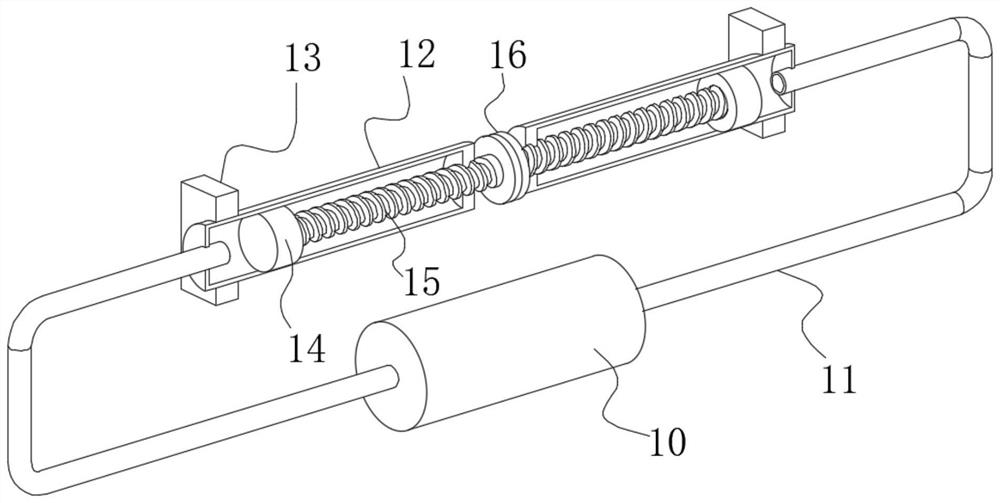

[0028] use Figure 1-Figure 6 A column moving type machine tool optical machine according to an embodiment of the present invention will be described below.

[0029] like Figure 1-Figure 6 As shown in the figure, a column mobile machine tool according to the present invention includes a bottom plate 1; a limit pin 2 is movably connected in the wall of the bottom plate 1, the bottom end of the limit pin 2 is fixedly connected to the ground, and the upper surface of the bottom plate 1 is connected to the ground. A sliding mechanism 3 is movably connected, and the outer surface of the sliding mechanism 3 is slidably connected with an external column 4. The sliding mechanism 3 includes an indicating mechanism 5. The lower surface of the indicating mechanism 5 is fixedly connected with the upper surface of the base plate 1. A sliding rail 6 is movably connected to the surface, and an adjusting mechanism 7 is movably connected to the wall of the sliding rail 6 .

[0030] By arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com