Electric machine tool

A technology for electric tools and motors, applied in the direction of manufacturing tools, electric components, electrical components, etc., can solve problems such as cumbersome, space problems, and troublesome brush replacement, and achieve the effect of simple methods and methods, and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

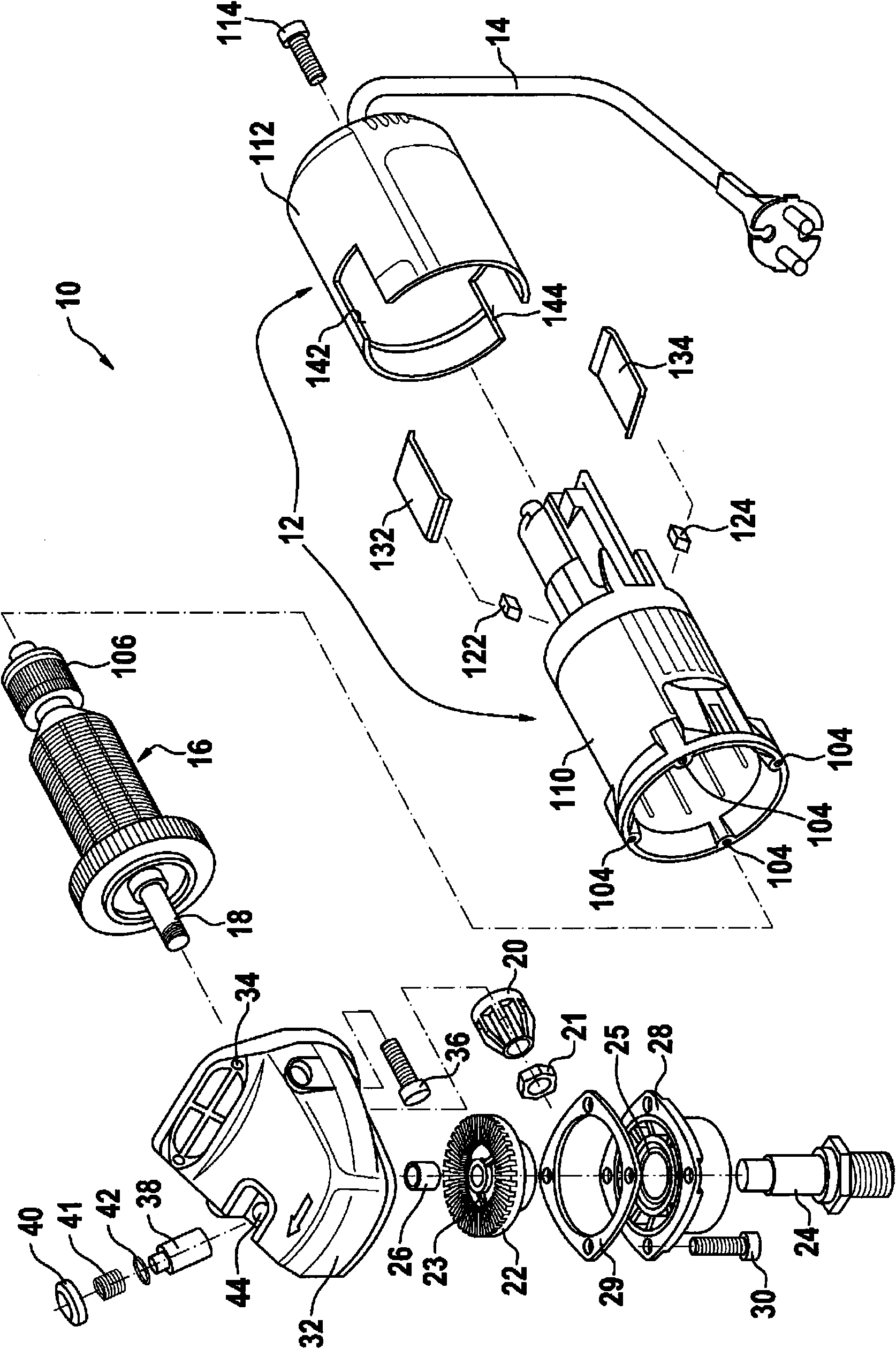

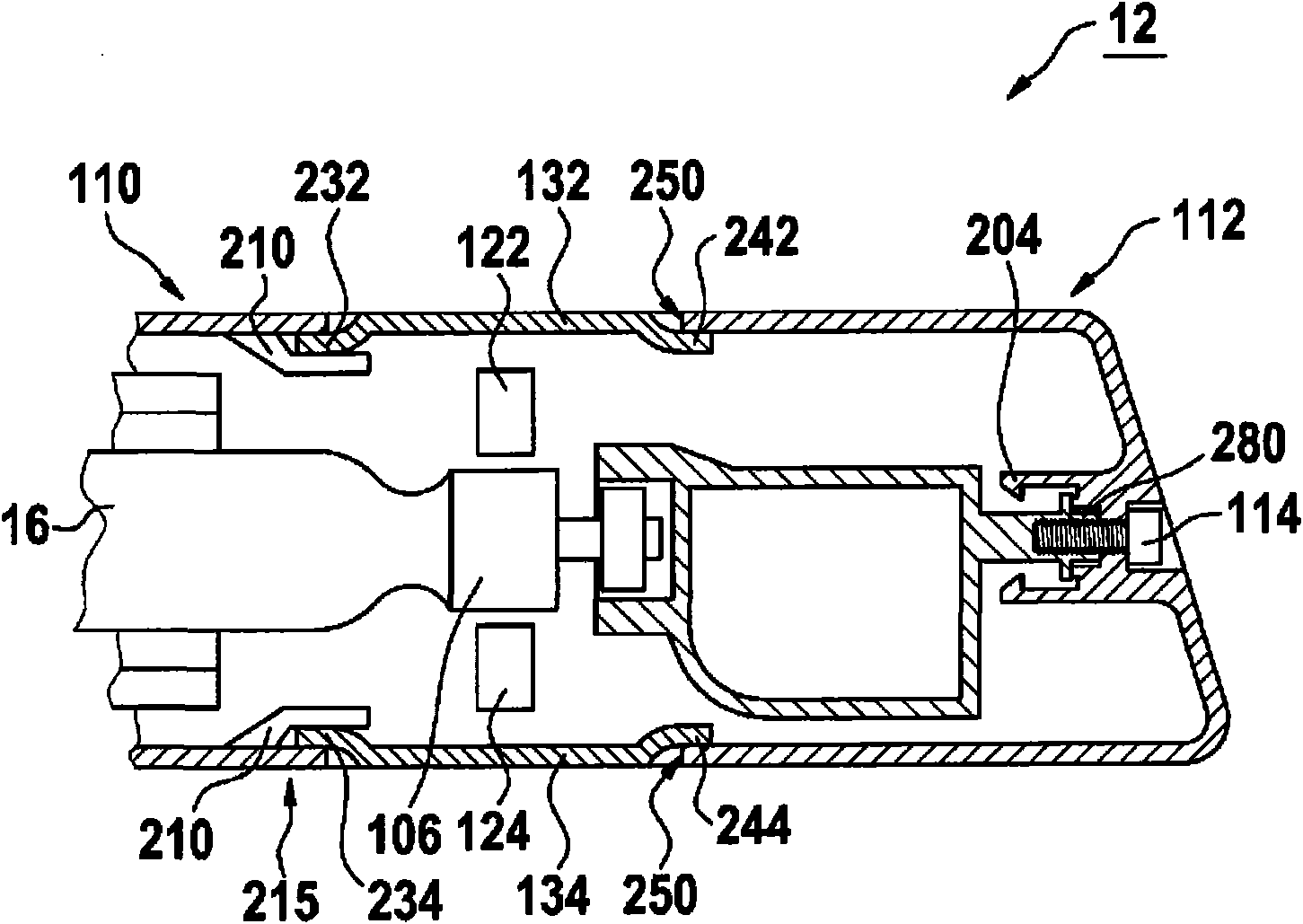

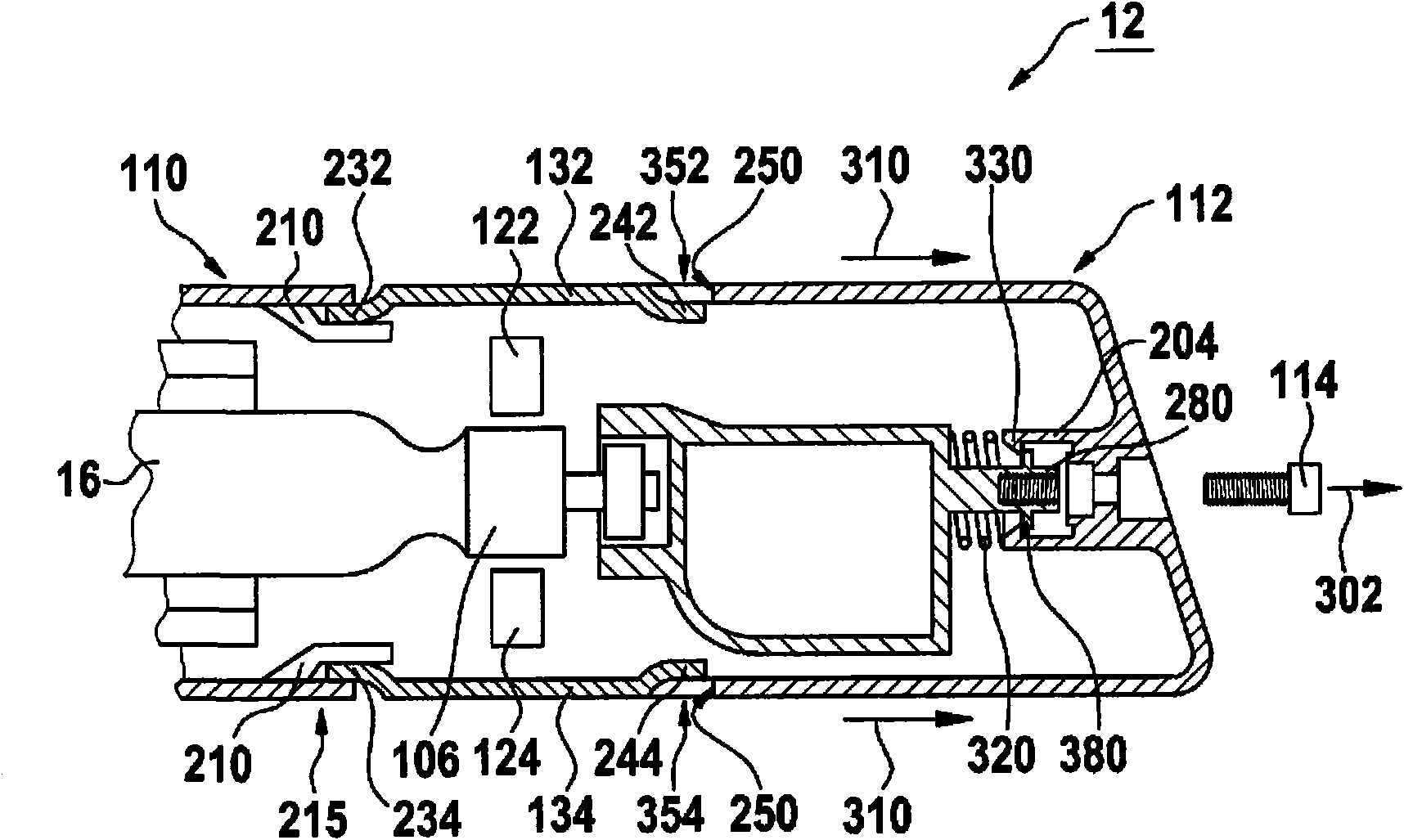

[0026] figure 1 An angle grinder 10 is shown according to an exemplary embodiment of the invention, which is constructed in the form of a pot and has an elongated, pot-shaped housing 12 . Inside the housing 12 a rotor 16 can be mounted with a motor shaft 18 on which a bevel gear 20 can be screwed axially by means of a nut 21 . The bevel gear 20 is intended to engage in the toothing of a disk gear 22 which has stop recesses 23 on its toothing side, which are formed by pressed-in recesses.

[0027] The disk gear 22 is mounted in a rotationally fixed manner on a drive shaft 24 which extends at right angles to the motor shaft 18 . The axial end region of the drive shaft 24 is surrounded by a bearing sleeve 26 which is arranged in an associated bearing bore of the transmission housing 32 . The other axial end region of the drive shaft is supported in a ball bearing 25 which is arranged in a bearing flange 28 . This bearing flange is screwed to the underside of the transmission h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com