Rapid forming process of plastic carrier band

A molding process and carrier tape technology, used in belts, other household appliances, household appliances, etc., can solve the problems of low material utilization, inability to manufacture carrier tapes, and small space, and achieve the effect of reducing costs and simplifying complex production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

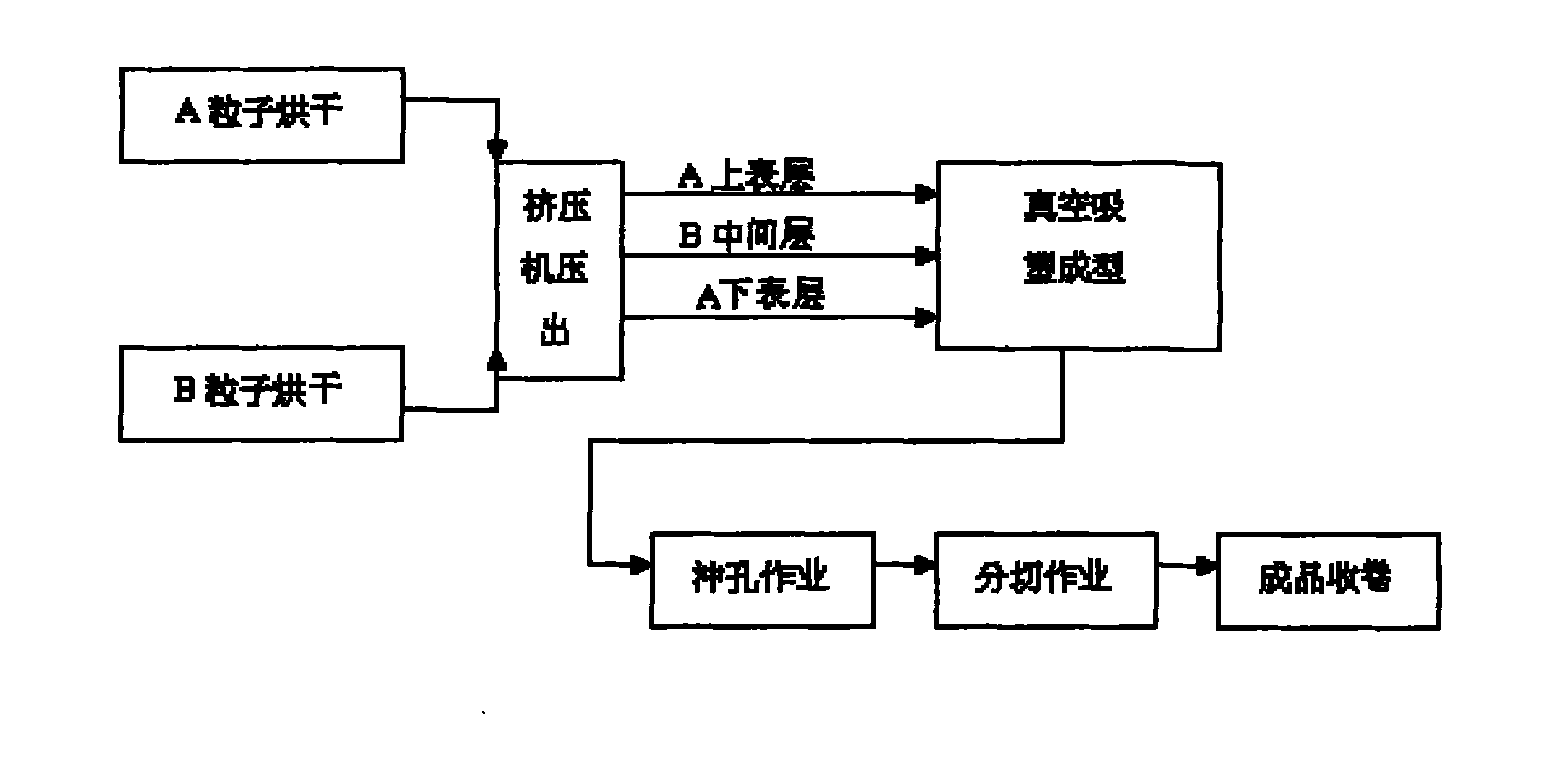

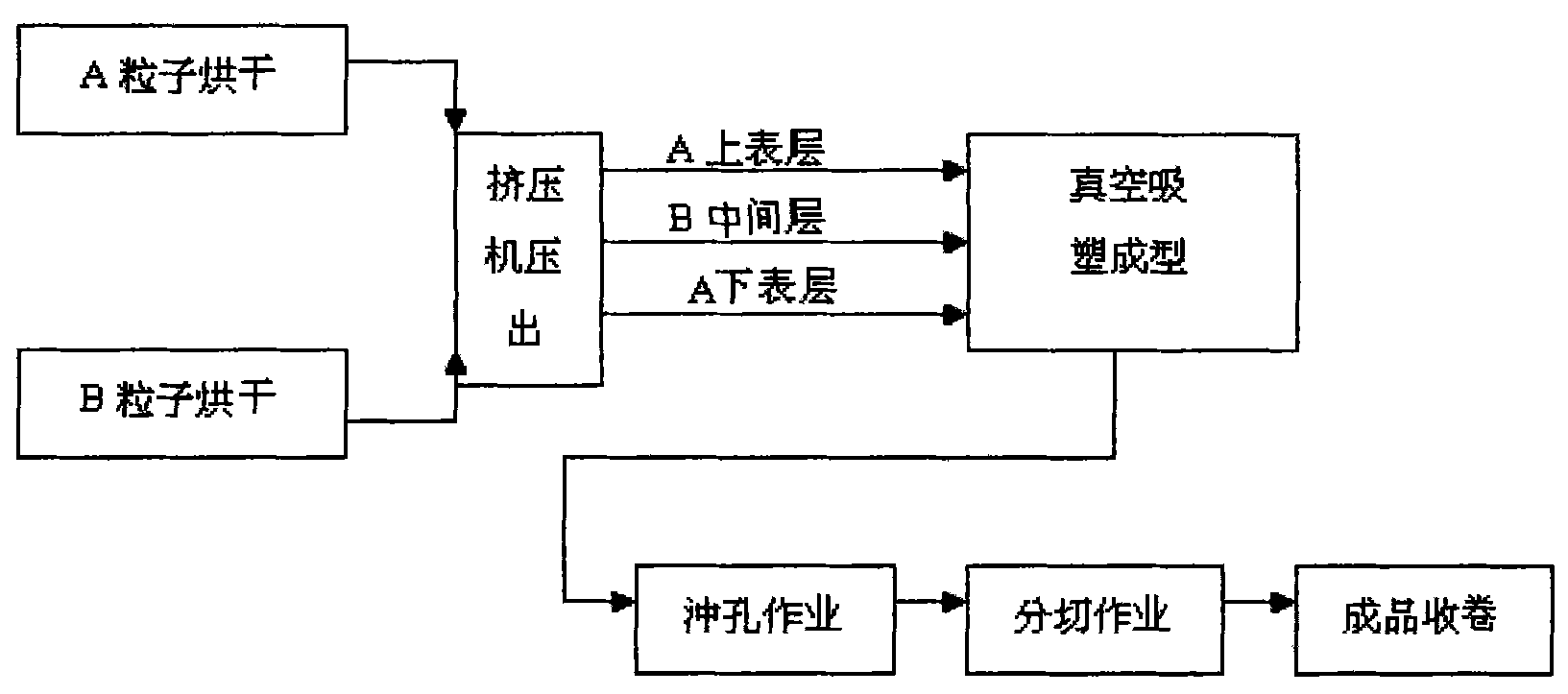

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the plastic carrier tape rapid prototyping process first dries two kinds of plastic particles A, B, and then puts the dried plastic particles A, B, and two kinds into an extruder to extrude into a plate, wherein A The plastic particles form the upper and lower surface layers of the board, and the B plastic particles form the middle layer of the board. Then, when the board is not cooled, it is made into a carrier tape by vacuum forming, and finally the punching operation, cutting operation and finished product collection are carried out. volume handling.

[0014] The two kinds of plastic particles A, B, and C can be any combination of any two of the following four transparent materials (the order represents the upper, middle, and lower layers of the material, and the material usage ratio can be adjusted arbit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com