Blade type automatic multipurpose cutting machine for blank and strap

A blade-type, multi-purpose machine technology, which is applied in the field of building materials machinery manufacturing, can solve the problems of inability to use automatic production lines, difficulty in realizing automatic production, and complicated mechanical operation processes, so as to save manpower, save time for steel wire replacement, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

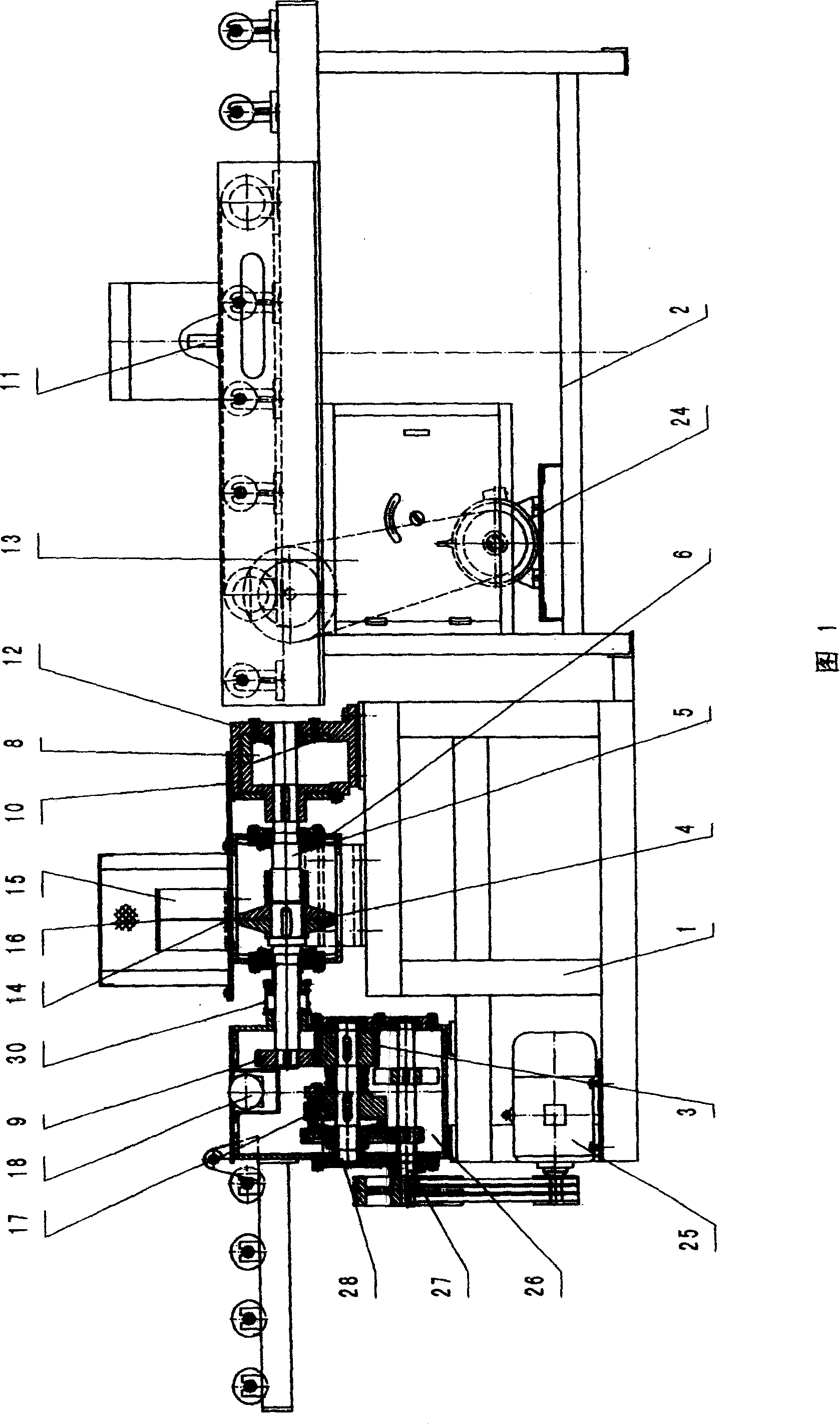

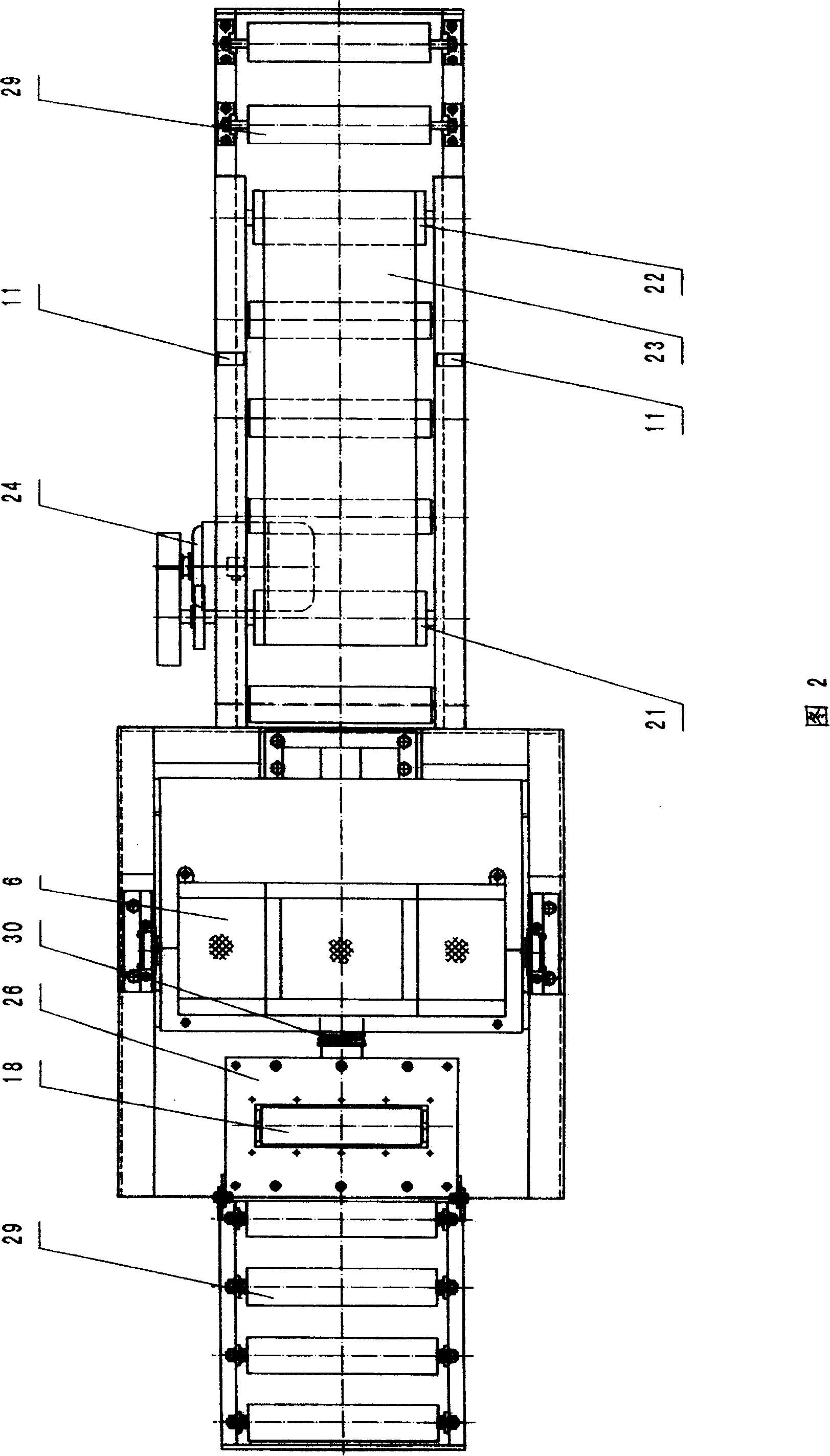

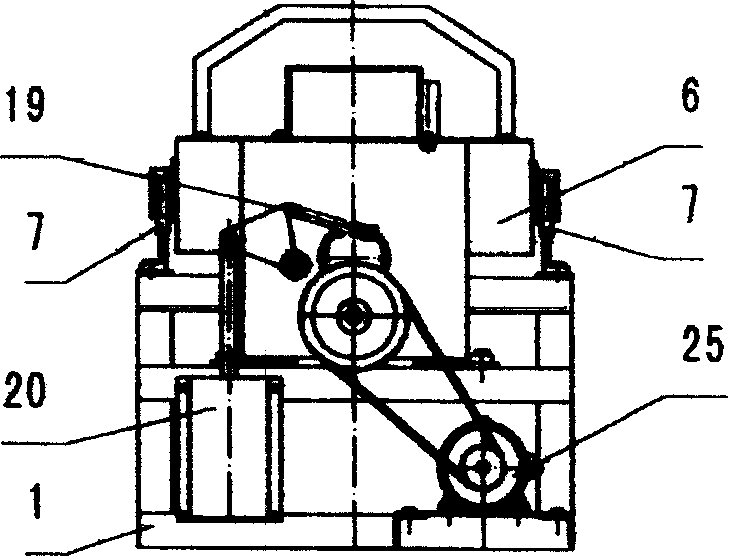

[0025] Describe the first embodiment of the present invention (for cutting) in conjunction with accompanying drawing 1,2,3,4,5.

[0026] A blade-type automatic strip cutting machine includes frames 1 and 2. The frame 1 is provided with a transmission part and a cutting part, and the frame 2 is provided with a strip feeding part.

[0027] Transmission part is made of cutting motor 25, transmission case 26, power input shaft 27, power output shaft 28, clutch assembly 17. The pulley on the cutting motor 25 main shafts links to each other with the pulley on the power input shaft 27 by belt, and the pinion on the power input shaft 27 meshes with the bull gear on the clutch shaft, and gear 3 is fixed on the power output shaft 28. Clutch assembly 17 is sleeved on the power output shaft 28, electromagnet 20 is fixed on the frame 1, clutch assembly 17 is hinged with one end of clutch pull rod 19, and the other end of clutch pull rod 19 is hinged with the piston end of electromagnet 20....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com