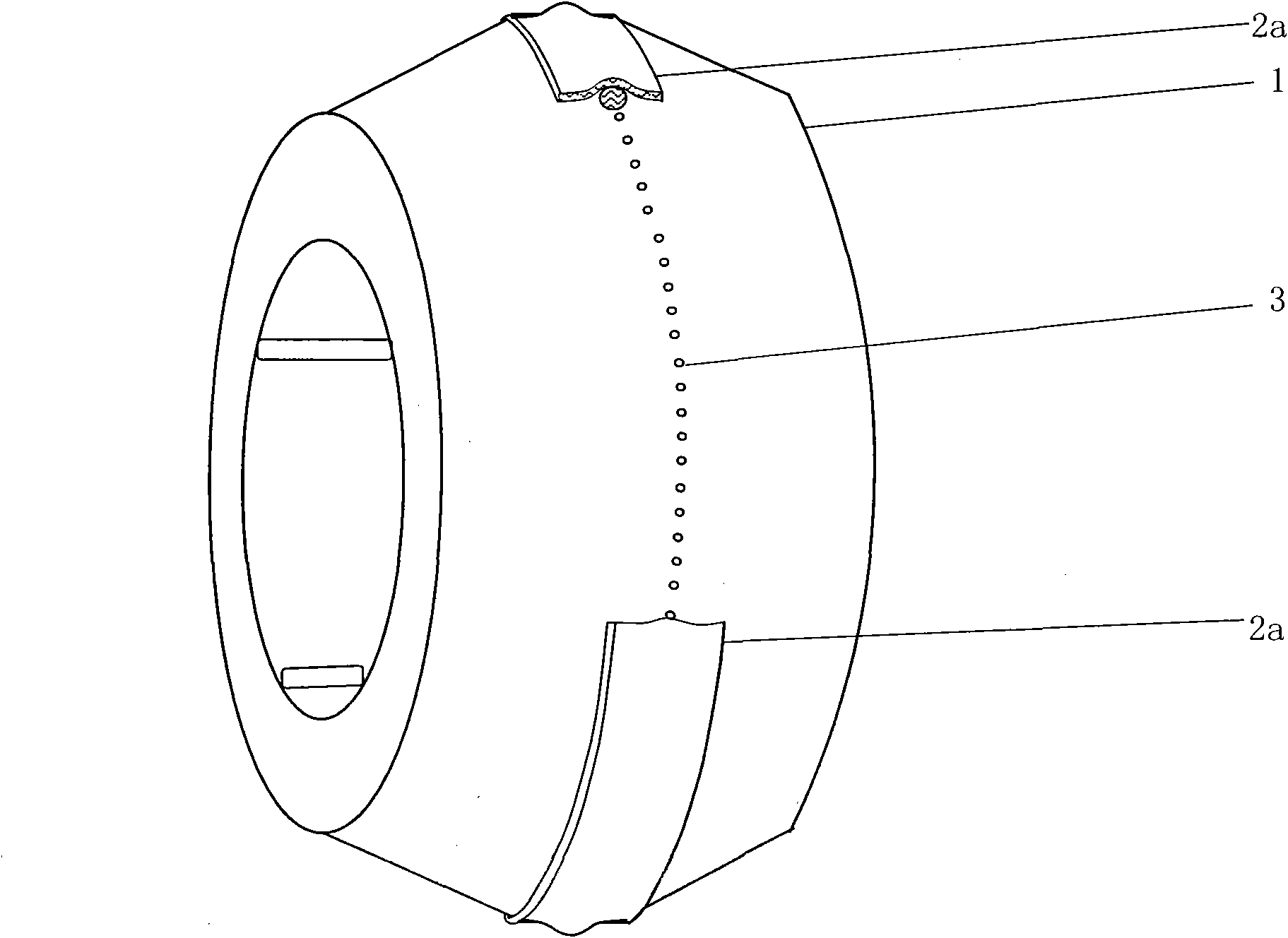

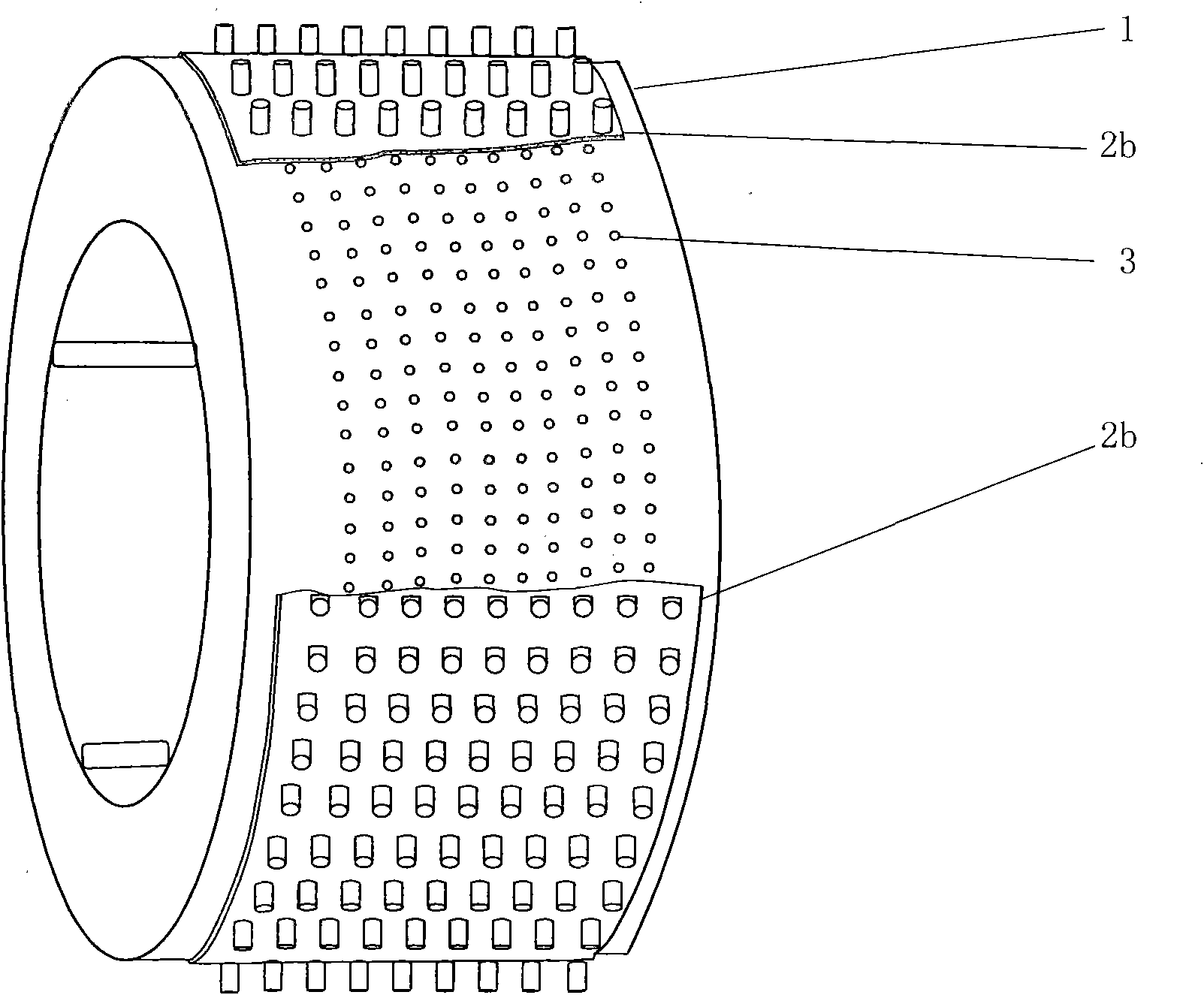

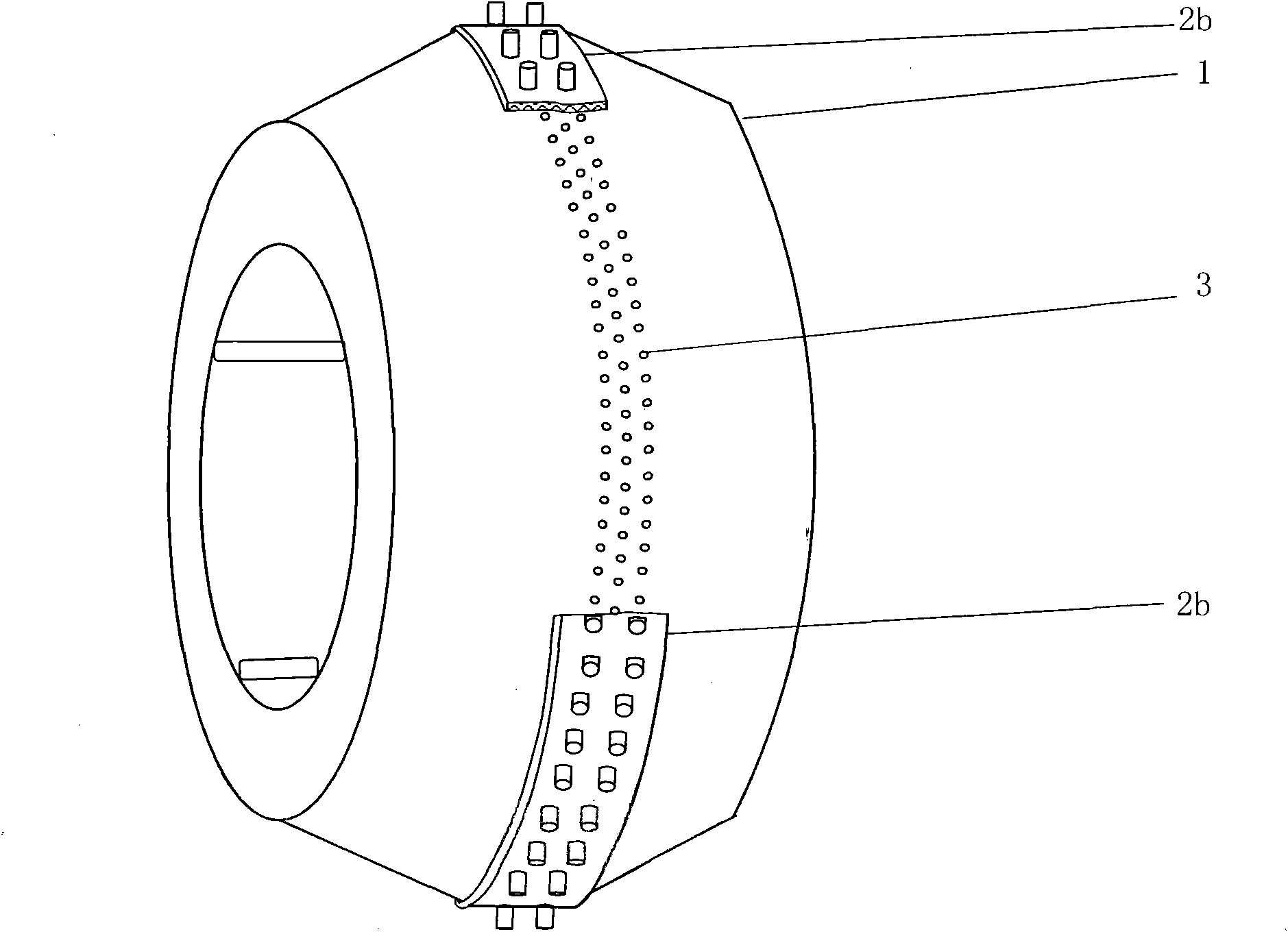

Single drum washing machine with dehydration holes capable of automatically opening and closing

A drum washing machine, automatic opening and closing technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of complex structure of the opening and closing device, easy water leakage, poor dehydration effect, etc., and achieve simple structure, not easy to leak, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The working process is briefly described below:

[0021] Before washing, the washing machine first detects the amount of clothes, and then the washing water flows through the water inlet pipe to the water tank provided above the transparent observation window 8 of the door 14 and is introduced into the drum 1. The detection of the water level is carried out by the water level sensor 13. Low-speed rotation, the control system detects and compares the water level multiple times during each rotation of the drum 1, and the highest water level is the current water level of the washing machine. Water level detection also can not establish water level sensor 13, can adopt the method for clothes amount detection to detect water intake earlier, then correct according to the water absorption rate of different clothes and get water level. During the water inlet process, the electric heating belt 9 heats the outer wall of the drum until the temperature measured by the temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com