Remote control type drilling bypass circulation valve

A circulation valve, remote control technology, applied in the direction of wellbore/well valve device, earthwork drilling, wellbore/well parts, etc., can solve the problem of wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

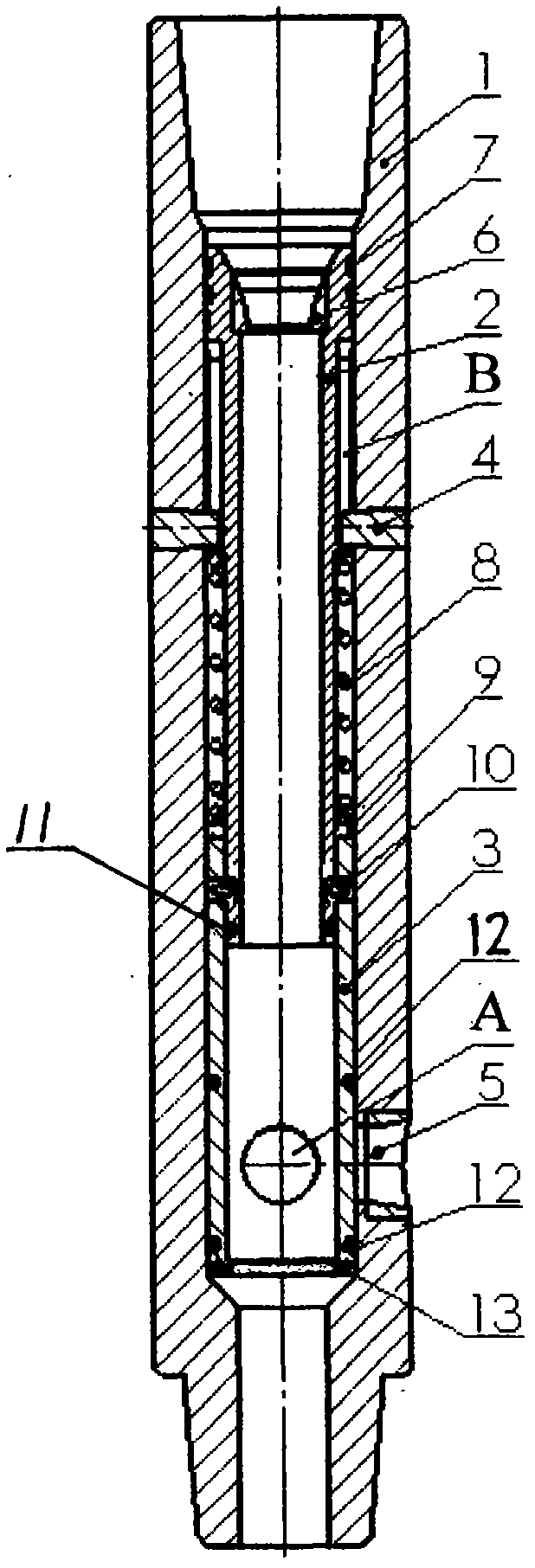

[0017] An embodiment is illustrated in conjunction with the accompanying drawings:

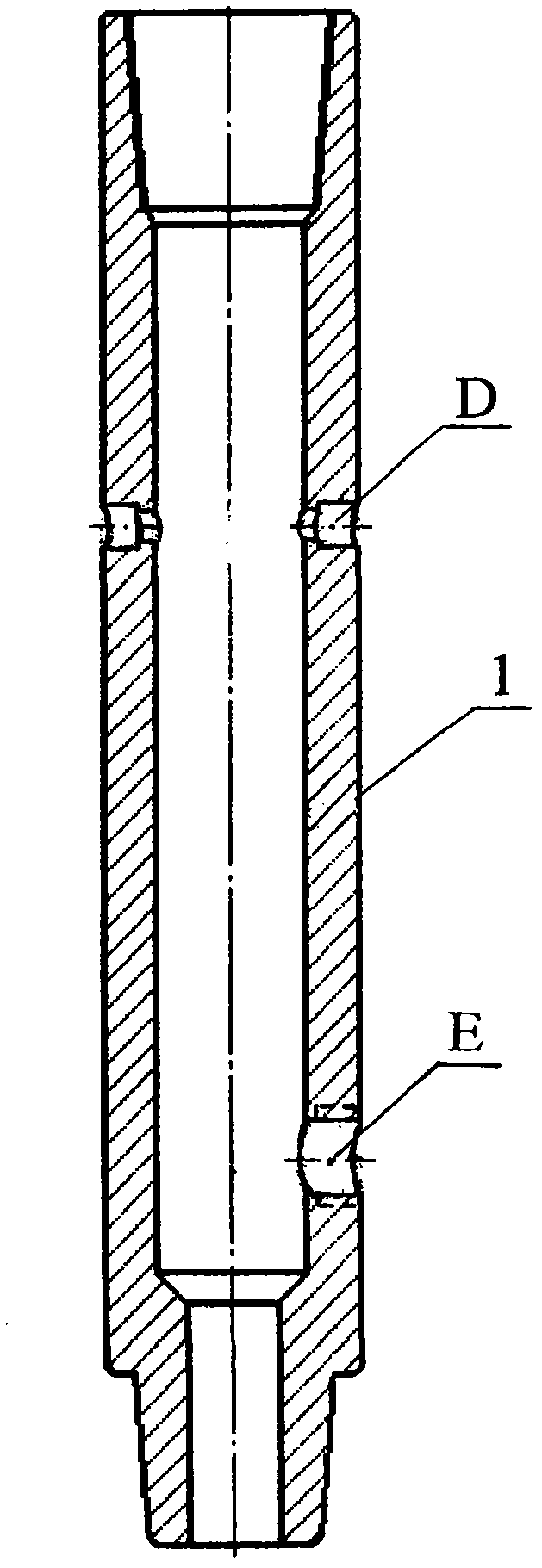

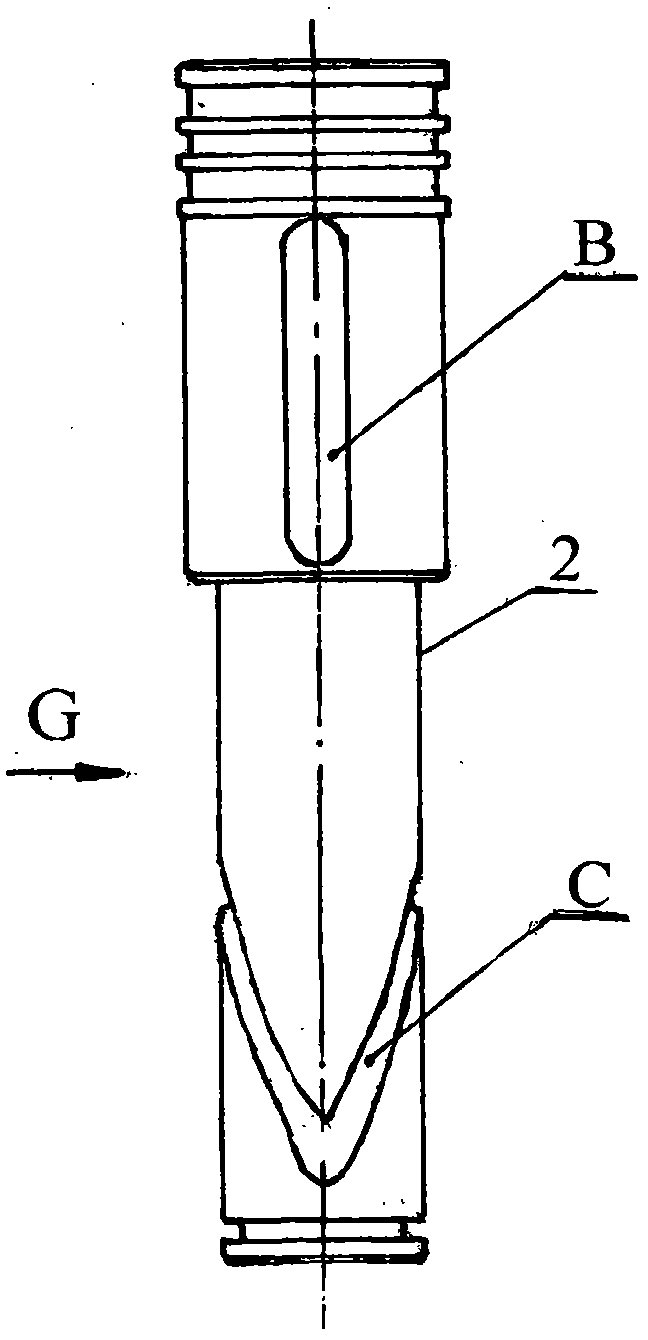

[0018] In the accompanying drawings, 1 is the shell, 2 is the control body, 3 is the switch body, 4 is the orientation pin (2 pieces), 5 is the bypass nozzle, 6 is the control nozzle, 7 is the upper sealing ring, 8 is the return spring , 9 is an upper bearing, 10 is a guide pin (2), 11 is a middle sealing ring, 12 is a lower sealing ring (two), and 13 is a lower bearing. A is the bypass hole in the lower part of the switch body 3, B is the orientation groove (two lanes) on the control body 2, C is the guide chute (four lanes) on the control body 2, D is the orientation pin 4 installed on the upper part of the housing 1 Radial holes (two), E is the radial hole for installing the bypass nozzle 5 at the bottom of the housing 1, and F is the radial hole for installing the guide pin 10 at the top of the switch body 3.

[0019] Depend on figure 1 As shown, the remote control drilling bypass circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com