Extracting and processing technology of food additive G-type alginate

A food additive and processing technology, which is applied in the field of algin preparation, can solve the problems of increasing the difficulty of algin extraction and low yield of algin, and achieve the effects of improving gelling performance, saving dosage, and promoting digestion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

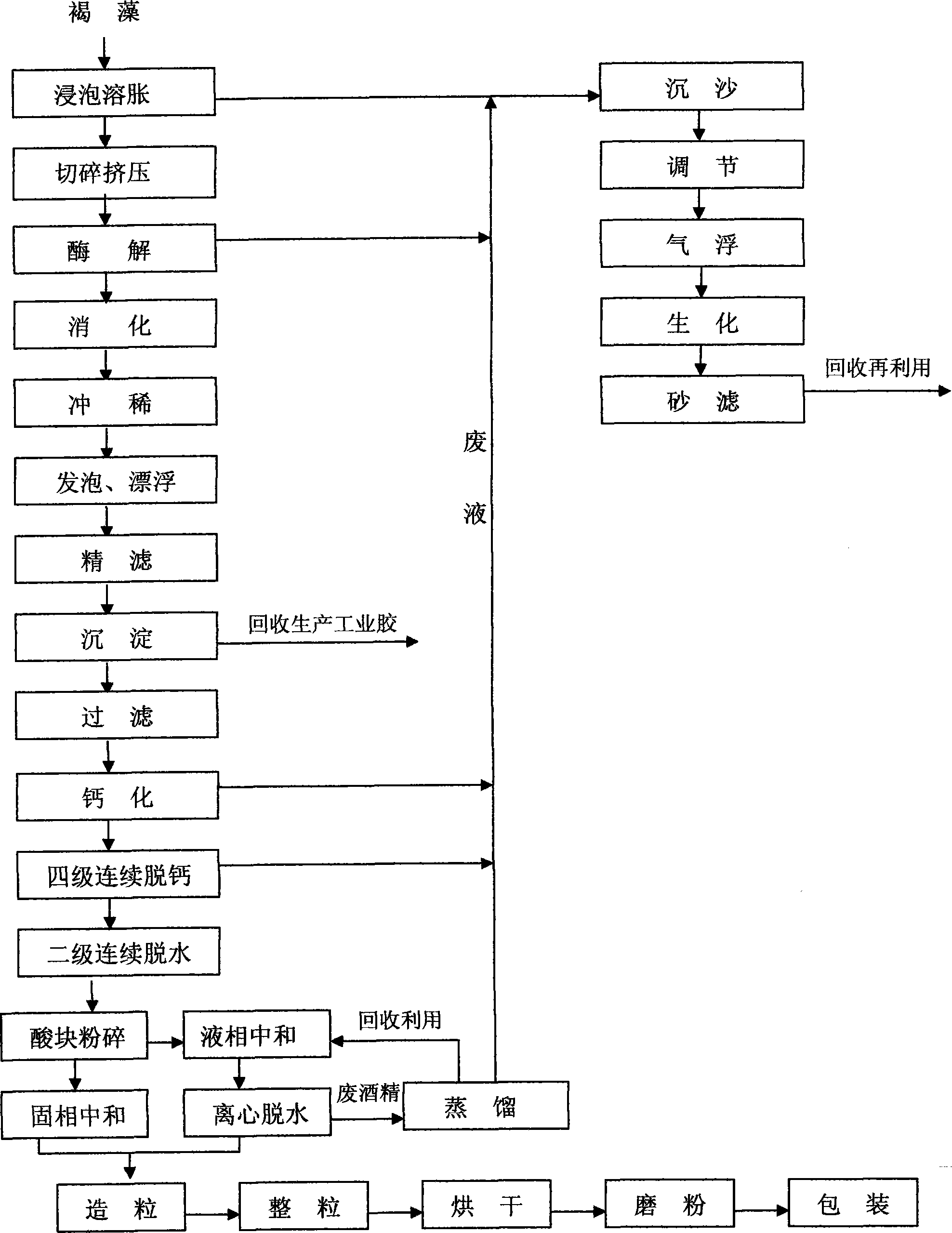

Image

Examples

specific Embodiment 1

[0010] (1) Soaking and swelling of brown algae

[0011] Add 1 times the water of the brown algae into the soaking tank, add a swelling agent, then evenly throw the brown algae into the soaking tank, and soak for 36 hours.

[0012] (2) Chopped, extruded, enzymatically hydrolyzed

[0013] Hang the brown algae into the extruder to chop and extrude, and the chopped and extruded brown algae enters the enzymolysis tank, adding 10ml of citric acid buffer solution with a pH of 5.0 for each gram of brown algae, and the amount of cellulase is 100u / g. Enzyme hydrolyzed at 50°C for 16 hours, then raised to 90°C to inactivate the enzyme.

[0014] (3) digestion

[0015] The temperature of the brown algae pumped into the digester is controlled at 50°C, supplemented with 15 times of hot water, and the amount of alkali added is 15% of the amount of dry brown algae.

[0016] (4) Dilute

[0017] Start the stirring cage, open the flushing water valve, the glue liquid enters the washing pool t...

specific Embodiment 2

[0044] (1) Soaking and swelling of brown algae

[0045] Add brown algae into the soaking pool 3 times of tap water, add a swelling agent, then throw the brown algae evenly into the soaking pool, and soak for 40 hours.

[0046] (2) Chopped, extruded, enzymatically hydrolyzed

[0047] Hang the brown algae into the extruder to chop and extrude, and the chopped and extruded brown algae enters the enzymolysis tank, adding 15ml of citric acid buffer solution with a pH of 5.0 for each gram of brown algae, and the amount of cellulase is 110u / g. Enzyme hydrolyzed at 50°C for 10 hours, then raised to 90°C to inactivate the enzyme.

[0048] (3) digestion

[0049] The temperature of the brown algae pumped into the digester is controlled between 60°C, supplemented to 17 times of hot water, and the amount of alkali added is 35% of the dry brown algae.

[0050] (4) Dilute

[0051] Start the stirring cage, open the flushing water valve, the glue liquid enters the washing pool through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com