Balanced type crescent seal gear pump

An internal gear pump, balanced technology, applied in the field of hydraulic components, can solve the problems of internal gear pump failure, shaft deformation, and affecting the service life of gear pump bearings, so as to reduce the force, reduce friction, and prevent glue failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

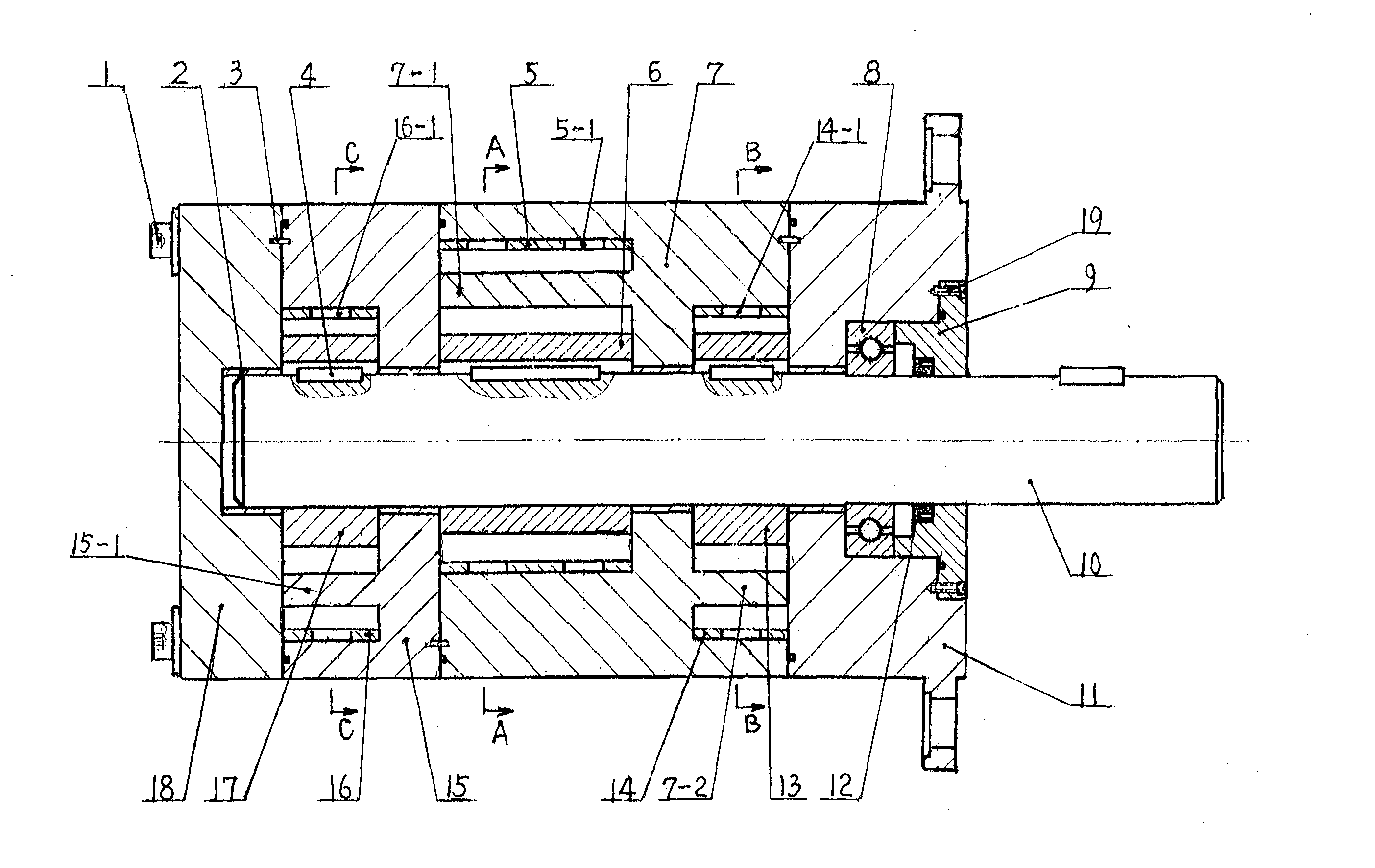

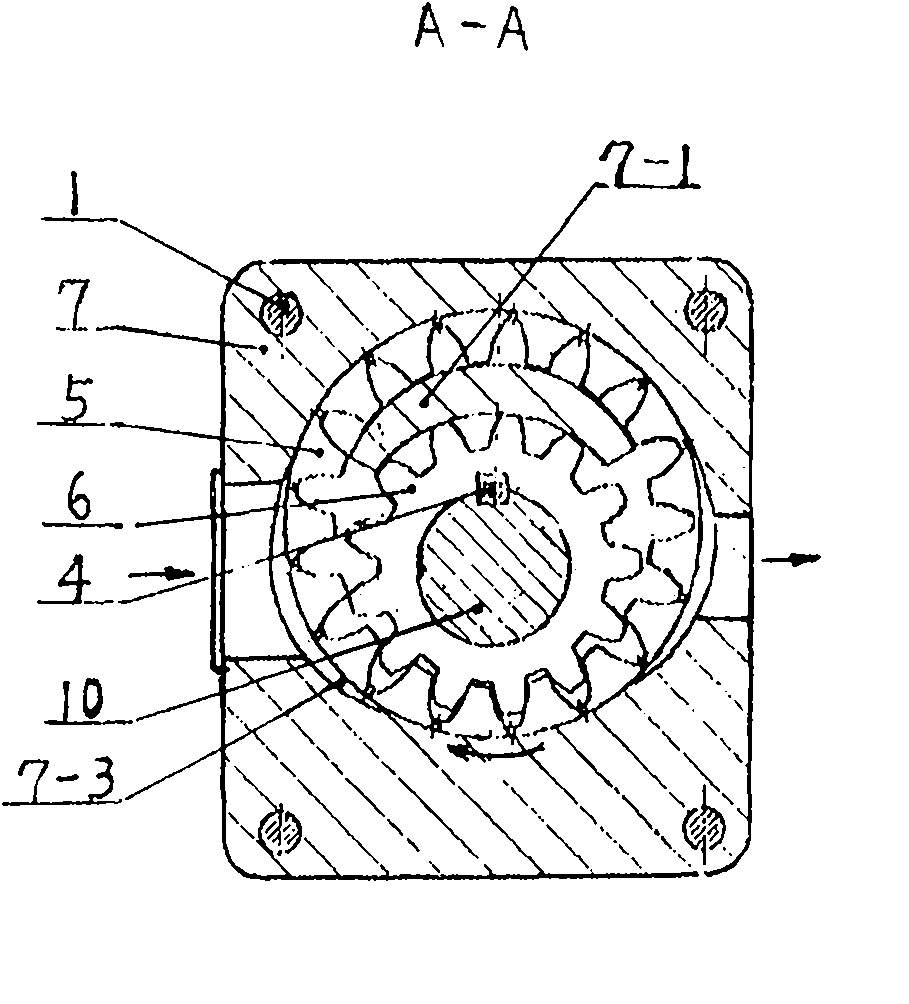

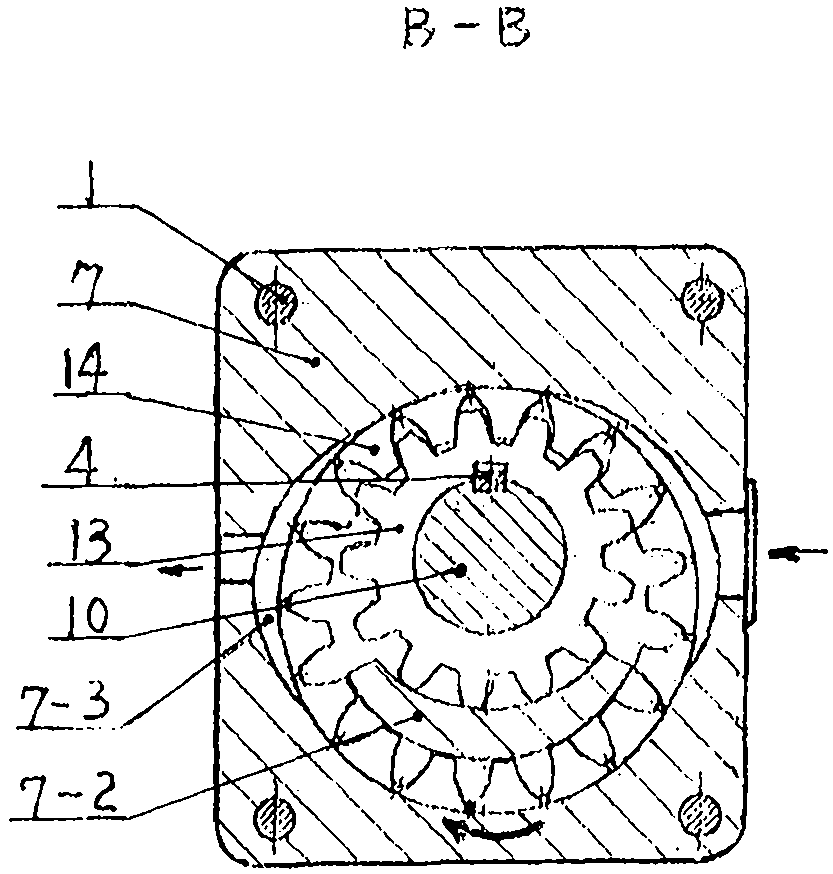

[0012] Examples, see attached Figure 1~4 , The left side of the pump body one 7 of the balanced internal gear pump is fixed with the pump body two 15 with the positioning pin 3 and the sealing ring. Main shaft 10 is housed with slide bearing 2 in pump body one 7 and pump body two 15 central holes. Use key 4 to adorn external gear-6 on the main shaft 10 on the left side in the pump body-7, the pump body-7 corresponding to external gear-6 is provided with internal gear-5 meshing with external gear-6, and internal gear-5 Establish meniscus-7-1 between external gear-6, meniscus-7-1 and pump body-7 are one, establish two rows of several internal gear-groove bottom holes 5-1 on internal gear-5. Use key 4 to adorn external gear two 13 on the main shaft 10 on the right side in the pump body one 7, the internal gear two 14 that the pump body one 7 of corresponding external gear 13 meshes with external gear two 13, the internal gear two 14 and the outside The meniscus two 7-2 that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com