Strip tail blending machine

A bending machine and frame technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the inconvenience of unloading, transporting and bundling steel coils at export, and easy damage to coilers and coil cars , the belt tail is not easy to roll tightly, etc., to achieve the effect of preventing excessive bending, long service life and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

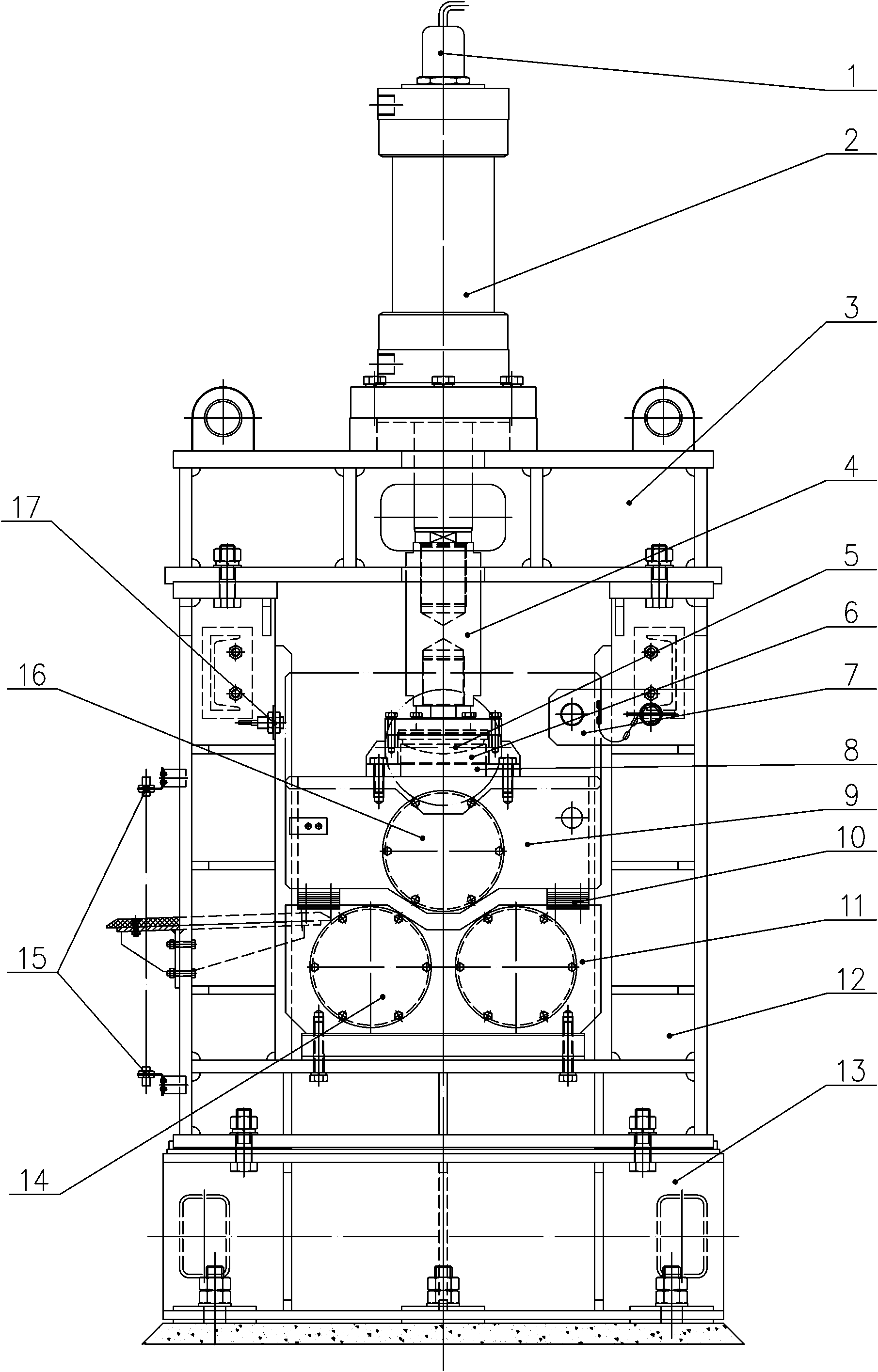

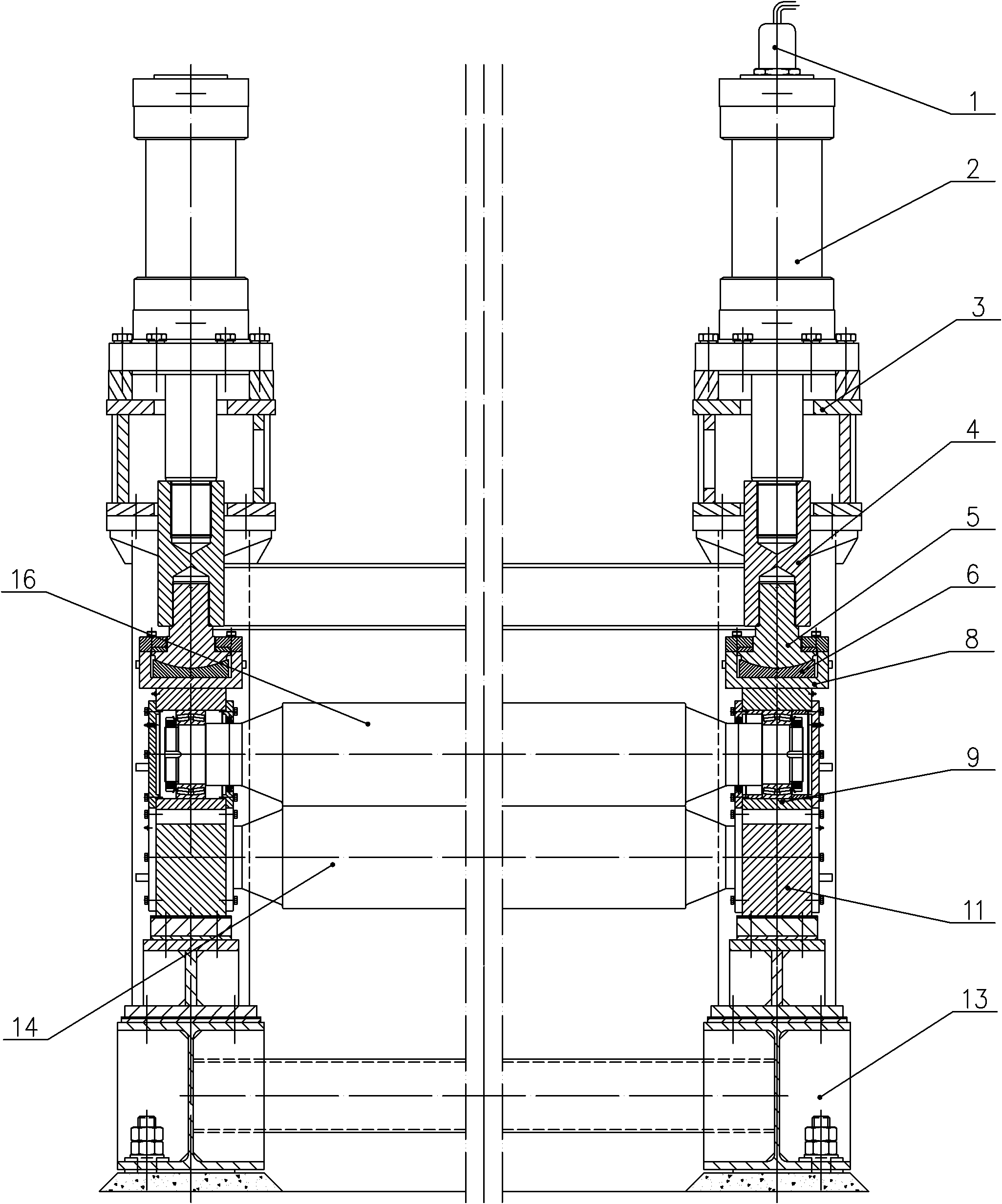

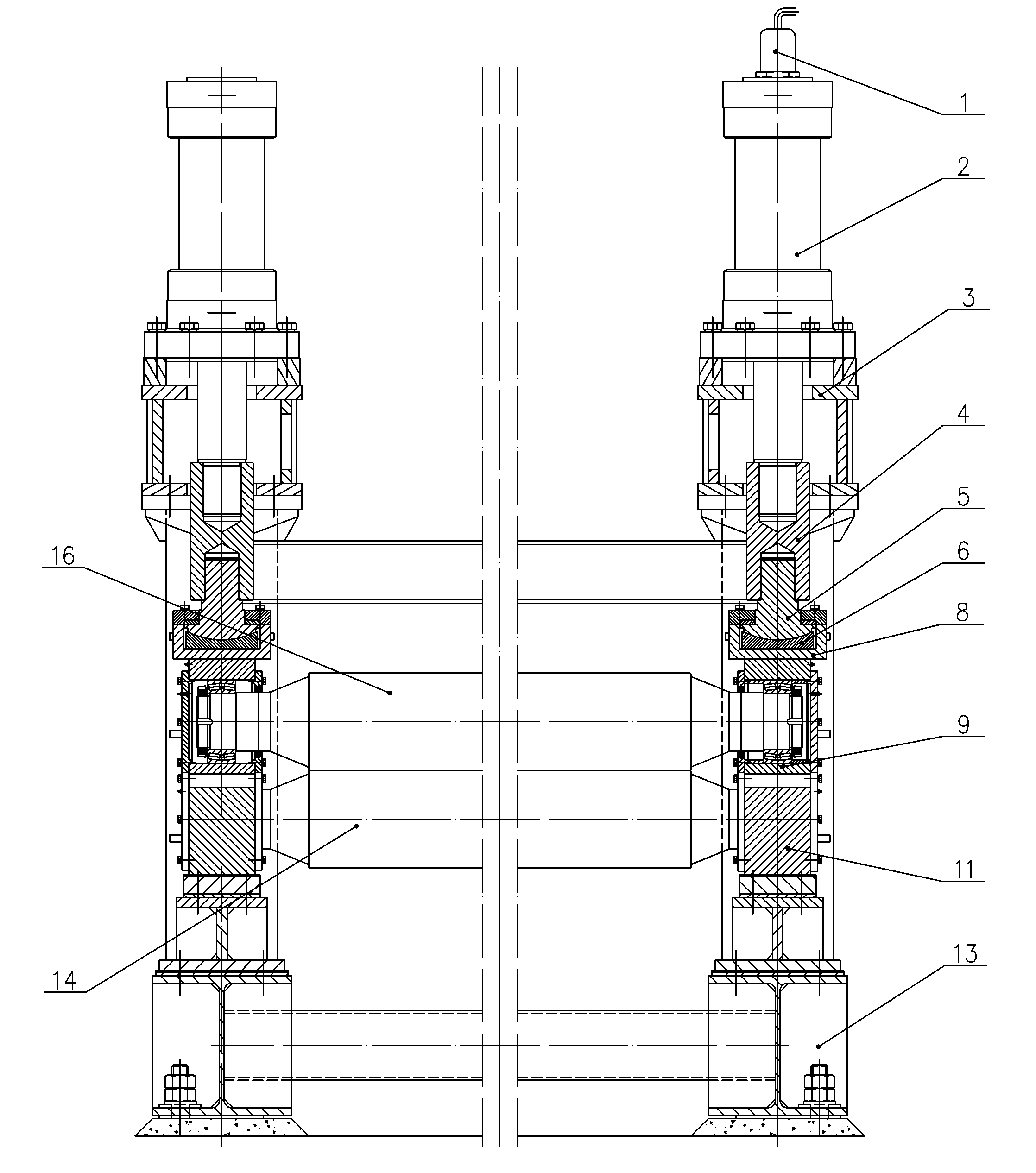

[0018] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, see figure 1 and figure 2 :

[0019] A kind of bending machine with tail according to the present invention comprises a frame, and the frame is in the form of a steel structure, which is formed by connecting three parts of the base 13, the U frame 12 and the upper frame 3, the base 13 is fixed on the ground foundation, and the U The frame 12 is in the shape of a U-shaped groove, and is connected to the base 13 with the opening upward, and the upper frame 3 is connected to the U frame 12 . The bending mechanism as a whole adopts a three-roller structure, the lower steel roller component is fixed in the U frame 12 of the frame, the driving element is arranged on the upper frame 3 at the top of the frame, and the driving element is connected with the upper steel roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com