Improved structure for sprayer of injection molding machine

A technology for improving the structure and injection molding machine, which is applied in the field of improving the structure of the nozzle of the injection molding machine. It can solve the problems of lowering the temperature and affecting the molding quality, and achieve the effect of ensuring the molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

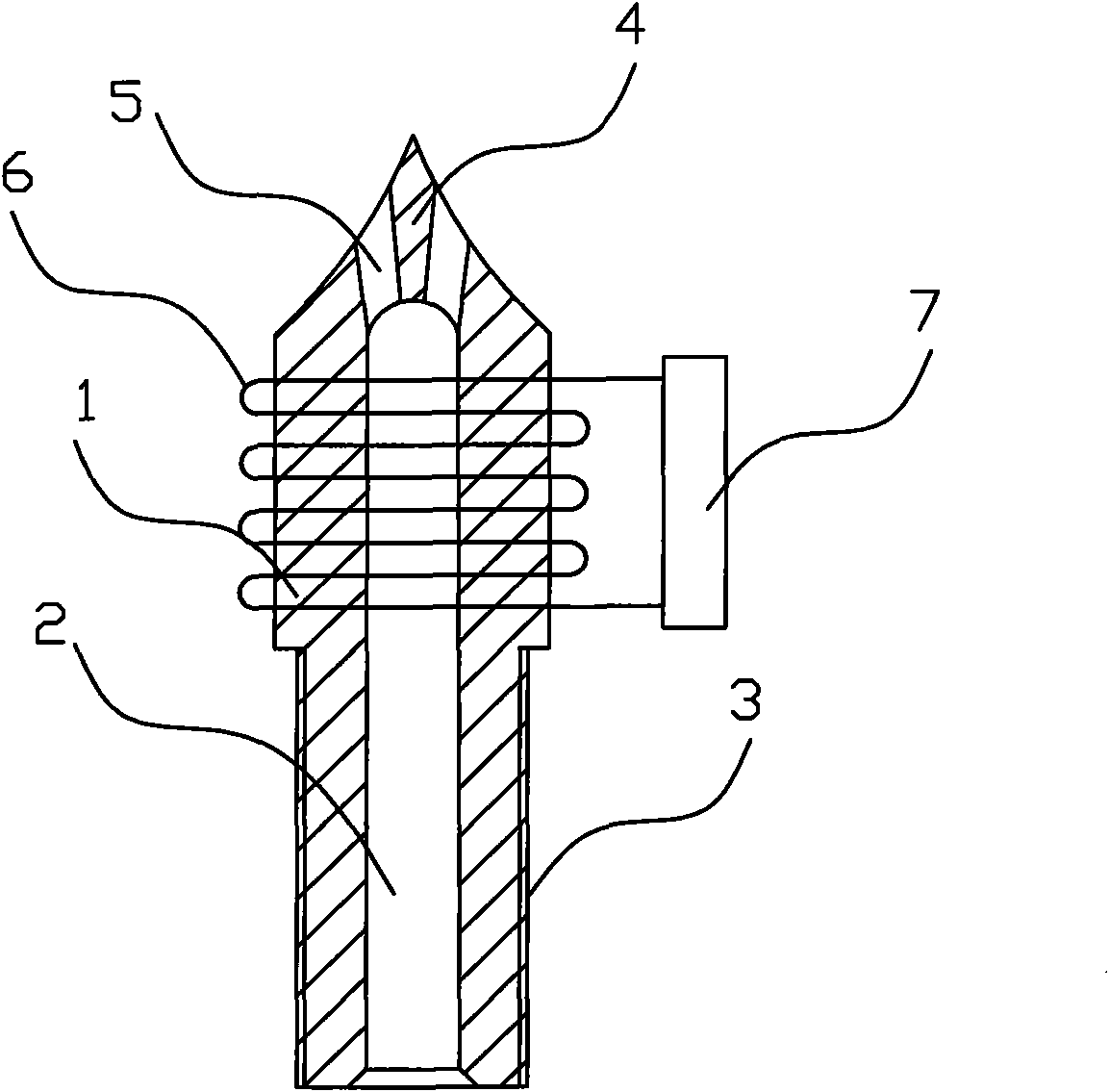

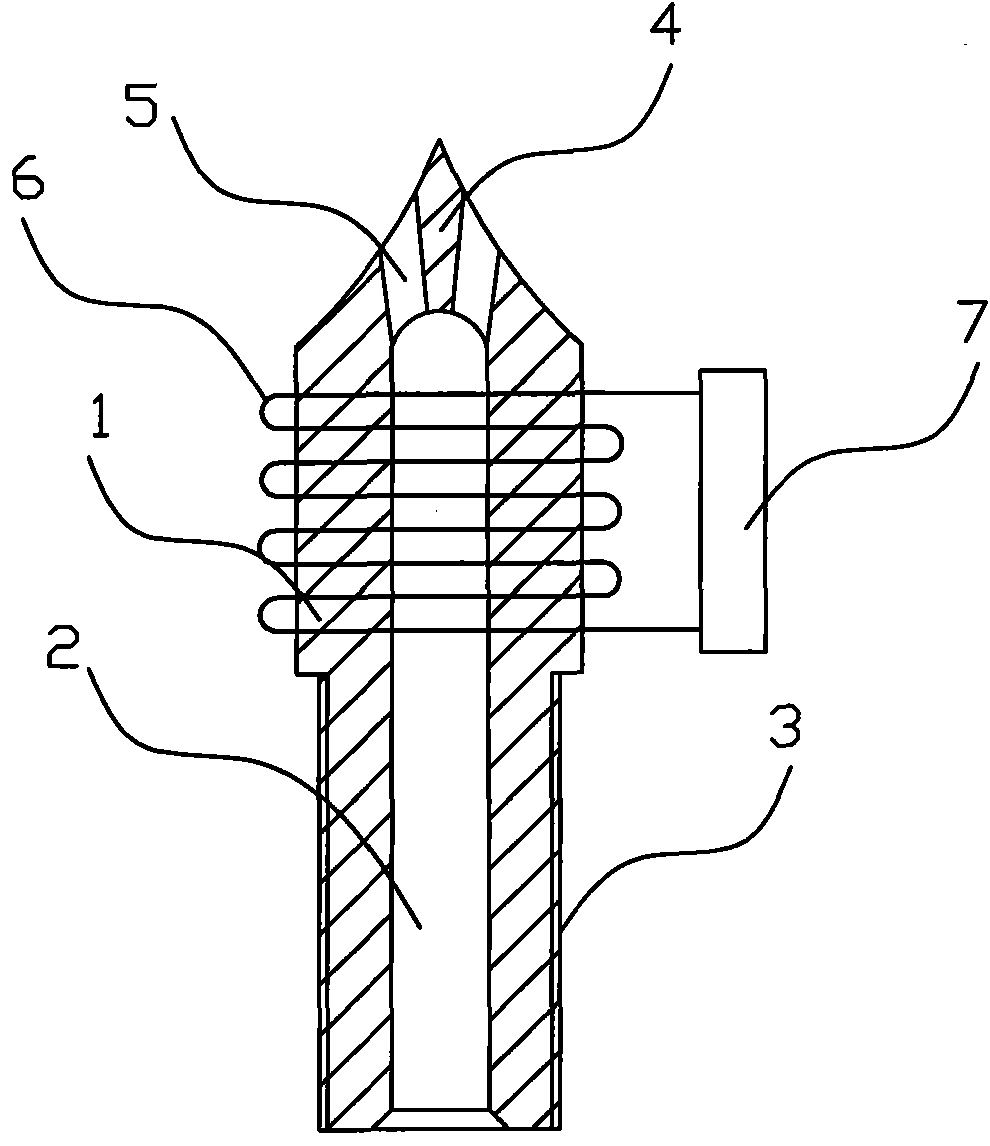

[0009] Such as figure 1 As shown, it is an embodiment of an improved structure of the nozzle of an injection molding machine according to the present invention, which includes a nozzle body 1, a nozzle flow channel 2 arranged inside the nozzle body and communicating with both ends of the nozzle body, and the outer surface of the rear end of the nozzle body 1 is provided with threads The connecting part 3 and the front end of the nozzle body 1 are provided with a nozzle 4, the nozzle communicates with the flow channel of the nozzle through the discharge channel 5, and the outer circumference of the nozzle body is provided with a heating device between the nozzle and the threaded connection. The heating device includes a heating coil 6 connected to a high-frequency induction heater 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap