Multi-functional self-balancing loading reaction frame

A reaction force rack, self-balancing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of the limitation of the experimental site of the reaction force rack and the inability to achieve self-balancing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

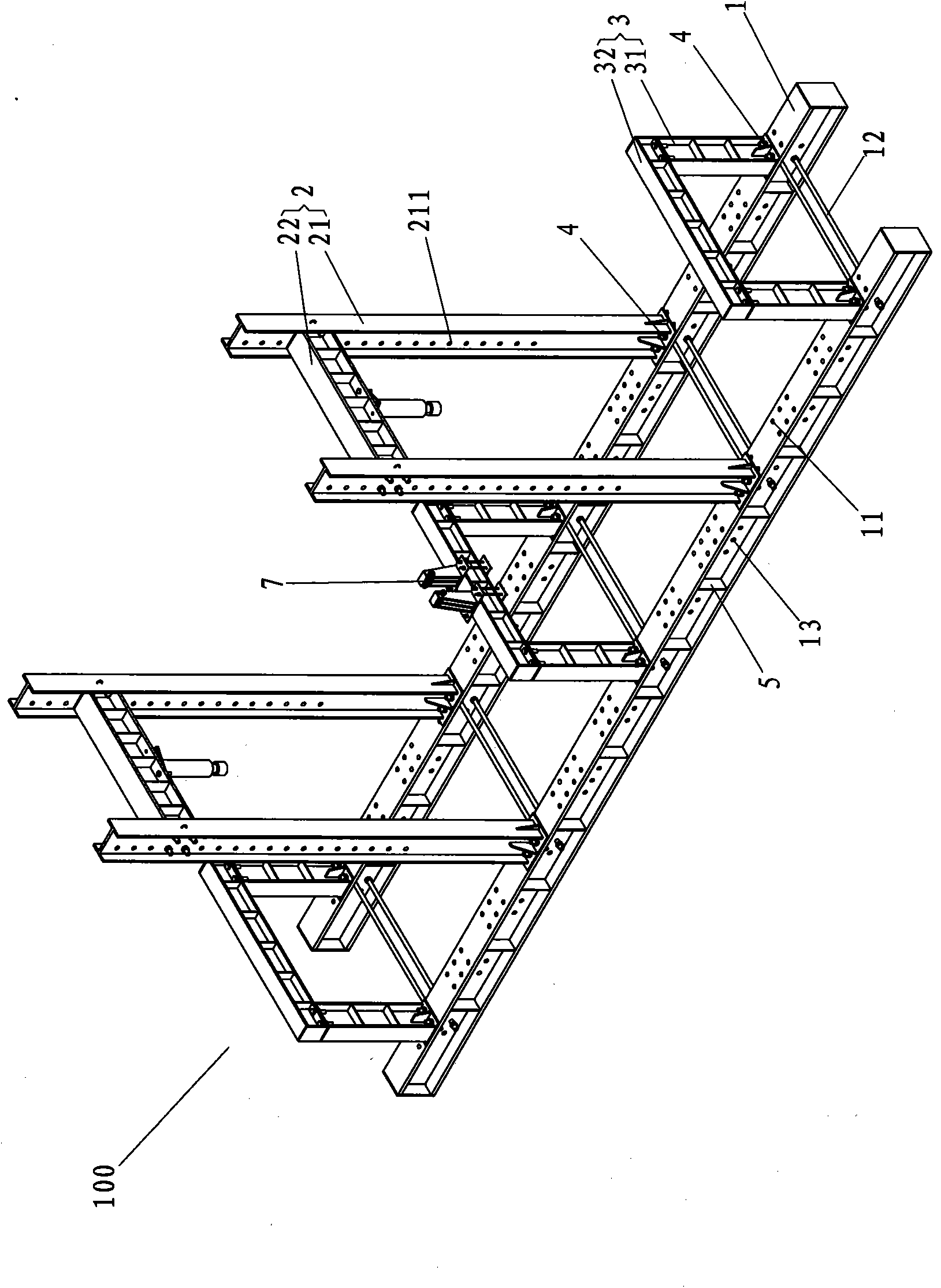

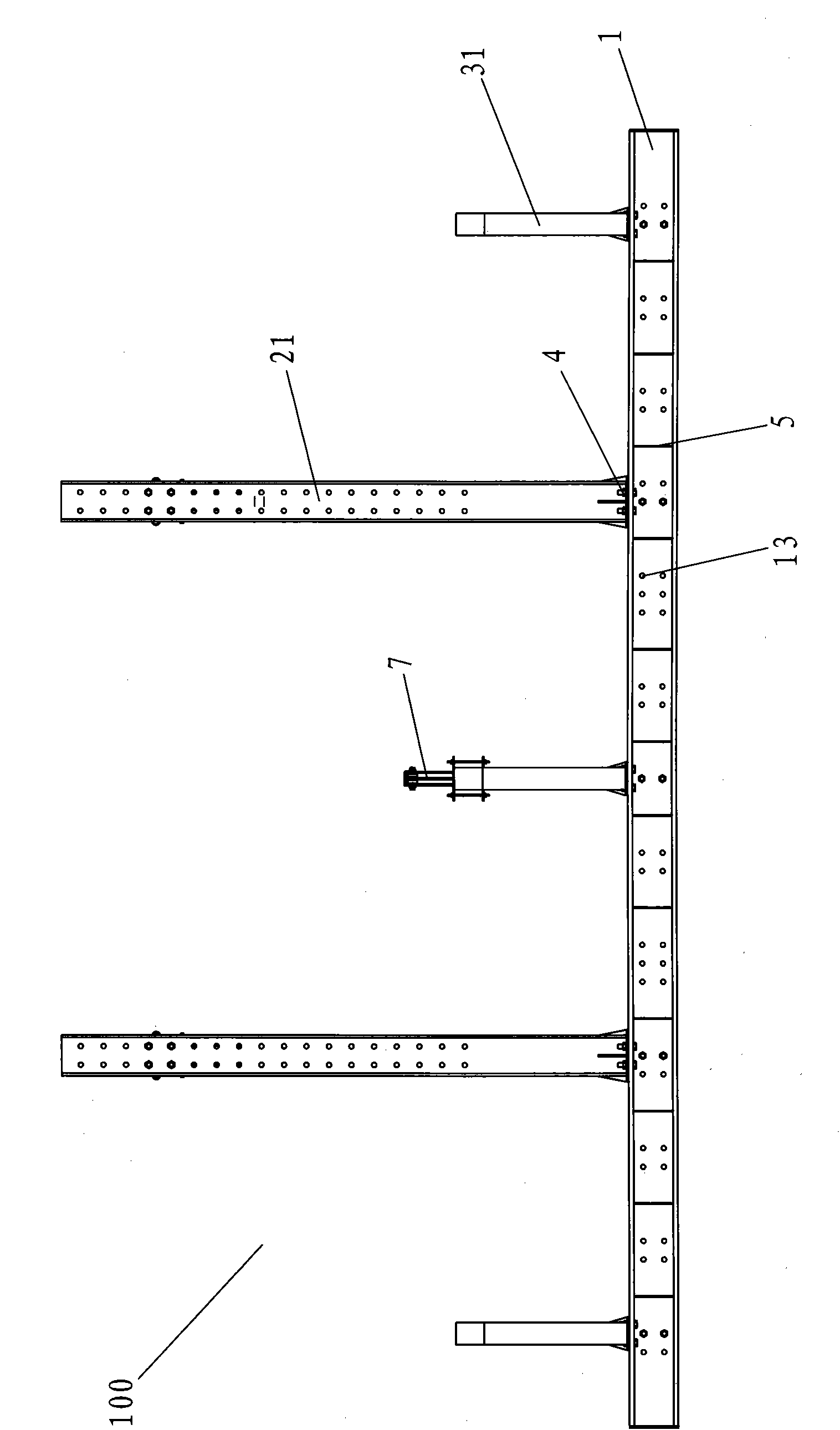

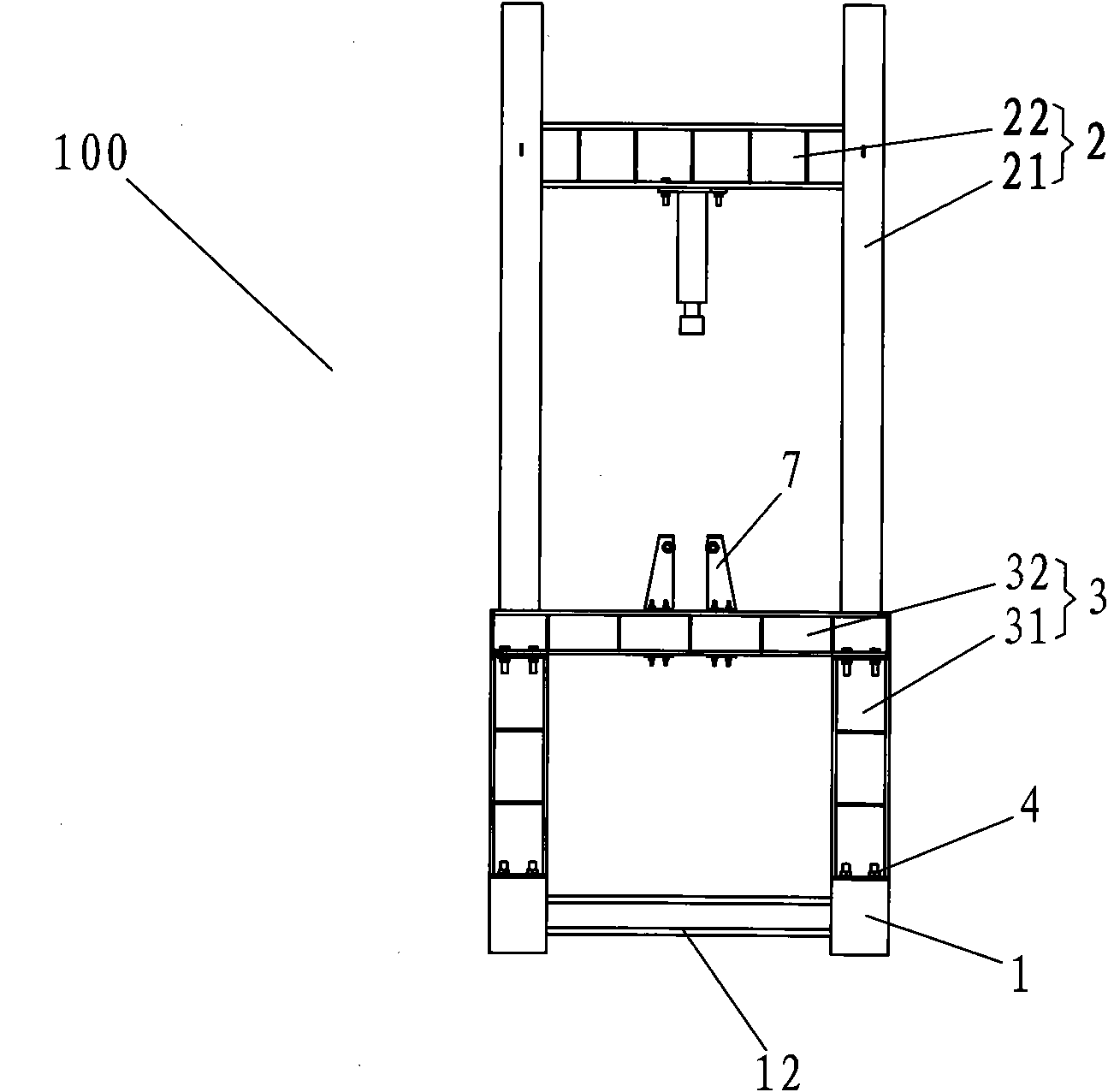

[0036] Such as Figure 1 to Figure 4 As shown, it is a multifunctional self-balancing loading reaction frame 100 related to the present invention, which includes a bottom main beam 1, a loading frame 2 and a support frame 3, wherein:

[0037] The bottom main girder 1 has two pieces arranged side by side;

[0038] The loading frame 2 has a loading column 21 and a loading beam 22, the loading column 21 is fixedly connected with the bottom main beam 1, and is respectively arranged on the corresponding position of each bottom main beam 1; the loading beam 22 is erected on two between the opposite loading columns 21, and the two ends are respectively fixedly connected with a loading column 21;

[0039] The support frame 3 has a support column 31 and a support beam 32, the support column 31 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com