Contact image sensor

An image sensor and contact technology, which is applied in image communication, instruments, banknote authenticity inspection, etc., can solve the problems of unrecognizable color-changing ink anti-counterfeiting marks, etc., and achieves a product suitable for mass production, reasonable in structural design, and small in size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

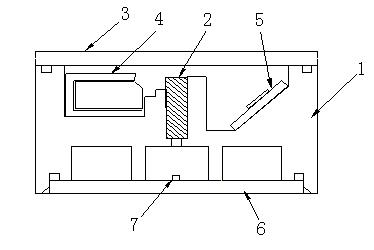

[0020] Embodiment 1: as image 3 As shown in the figure, the frame 1, the lens 2, the light-transmitting plate 3, the light guide strip structured light source 4, the LED array structured light source 5, the circuit board accommodating the photoelectric conversion chip 6, the photoelectric conversion chip 7, and the non-reflective film 8 are marked. For example, the light sources on both sides of the lens are light guide strip structure and LED array structure respectively. The two light sources have different luminous angles. The luminous angles of the two light sources can be adjusted according to the needs. The luminous angle of one of the light sources can be adopted relative to the lens axis. An angle of 20° or 30°, the light emitting angle of another light source can adopt an angle of 60° to 80° relative to the axis of the lens.

Embodiment 2

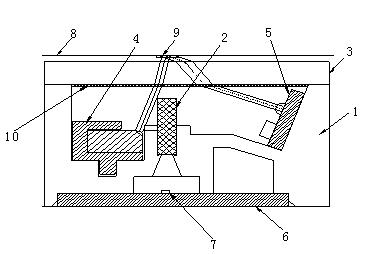

[0021] Embodiment 2: as Figure 4 As shown in the figure, the frame 1, the lens 2, the light-transmitting plate 3, the light guide strip structured light source 4, the light guide strip structured light source 5, the circuit board containing the photoelectric conversion chip 6, the photoelectric conversion chip 7, and the non-reflective film 8, this The light sources on both sides of the lens in the embodiment adopt a light guide strip structure. The two light sources have different light emitting angles. The light emitting angles of the two light sources can be adjusted according to the needs. The light emitting angle of one of the light sources can be 20° or 20° relative to the axis of the lens. For an angle of 30°, the light emitting angle of the other light source can adopt an angle of 60° to 80° relative to the axis of the lens.

Embodiment 3

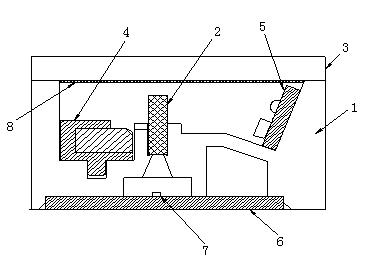

[0022] Embodiment 3: as Figure 5 As shown in the figure, the frame 1, the lens 2, the light-transmitting plate 3, the LED array structure light source 4, the LED array structure light source 5, the circuit board 6 accommodating the photoelectric conversion chip, the photoelectric conversion chip 7, and the non-reflective film 8 are marked. For example, the light sources on both sides of the lens adopt LED array structure. The two light sources have different light angles. The light angles of the two light sources can be adjusted according to the needs. The light angle of one light source can be 20° or 30° relative to the lens axis. The light emitting angle of another light source can be 60° to 80° relative to the axis of the lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com