Microstructural multi-layer composite distributor

A composite dispenser and microstructure technology, applied in the field of multi-layer composite dispensers, can solve the problems of bulky and unrealizable dispensers, and achieve offsetting overload force, strong flexibility, strength and tear resistance, and good viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

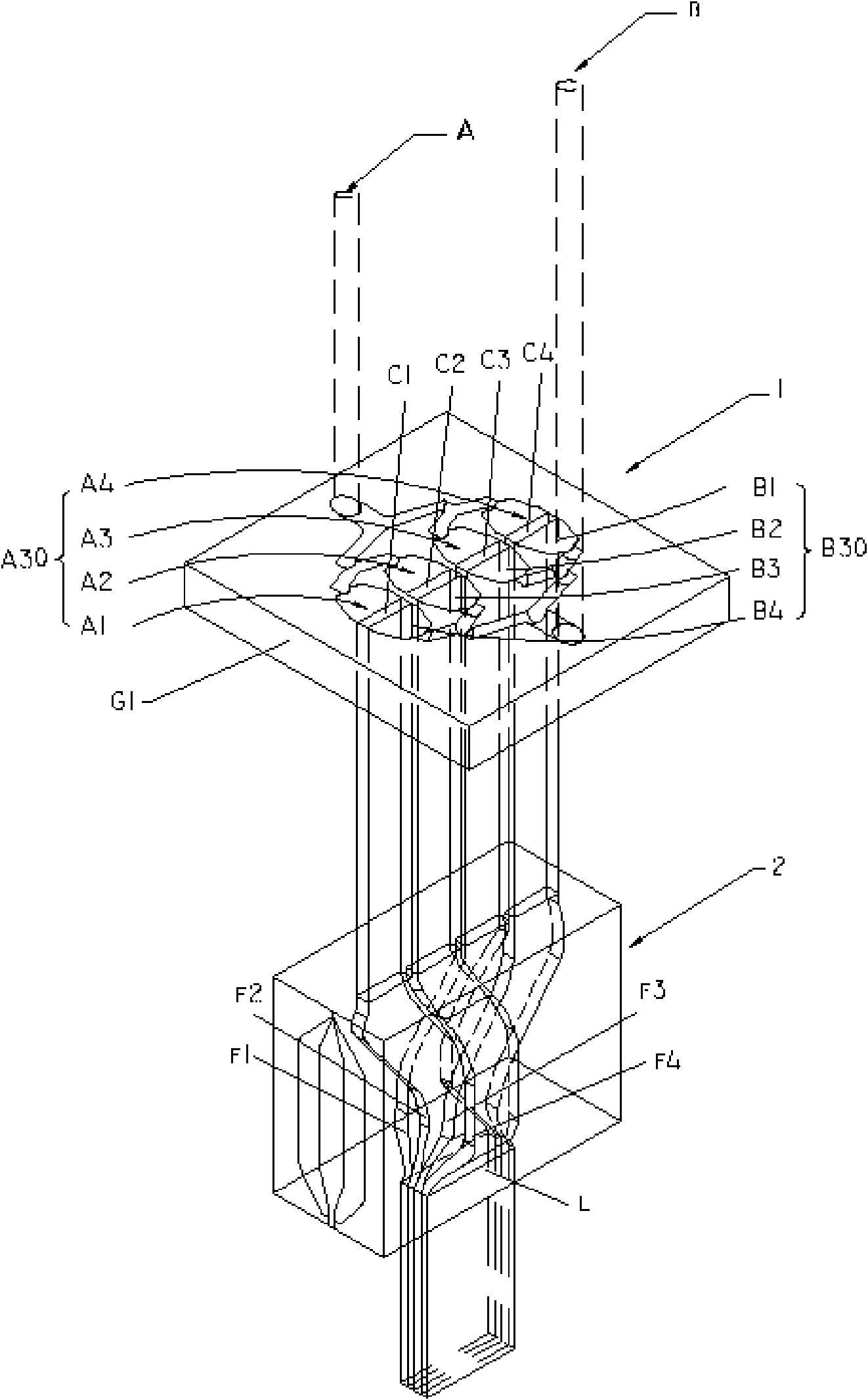

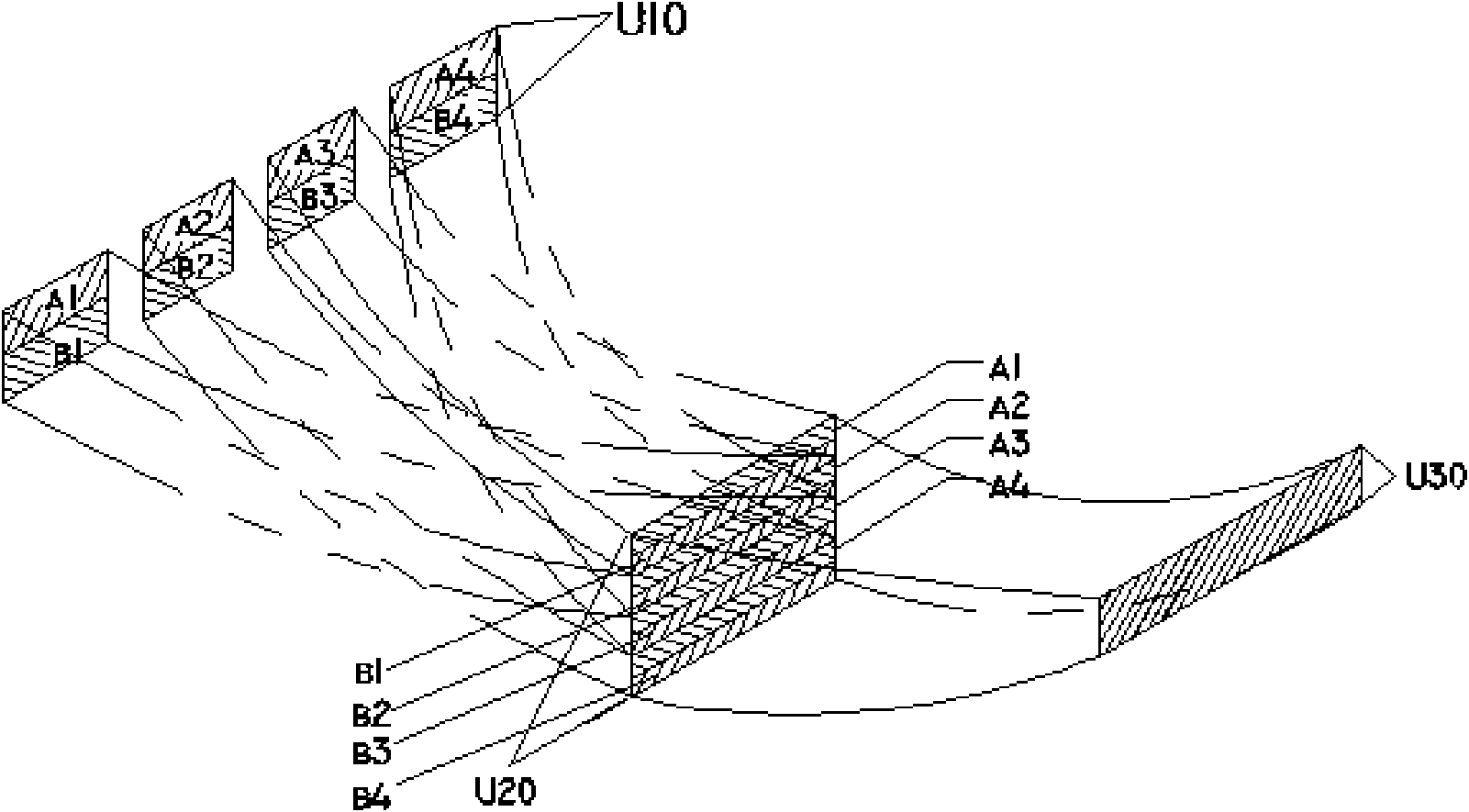

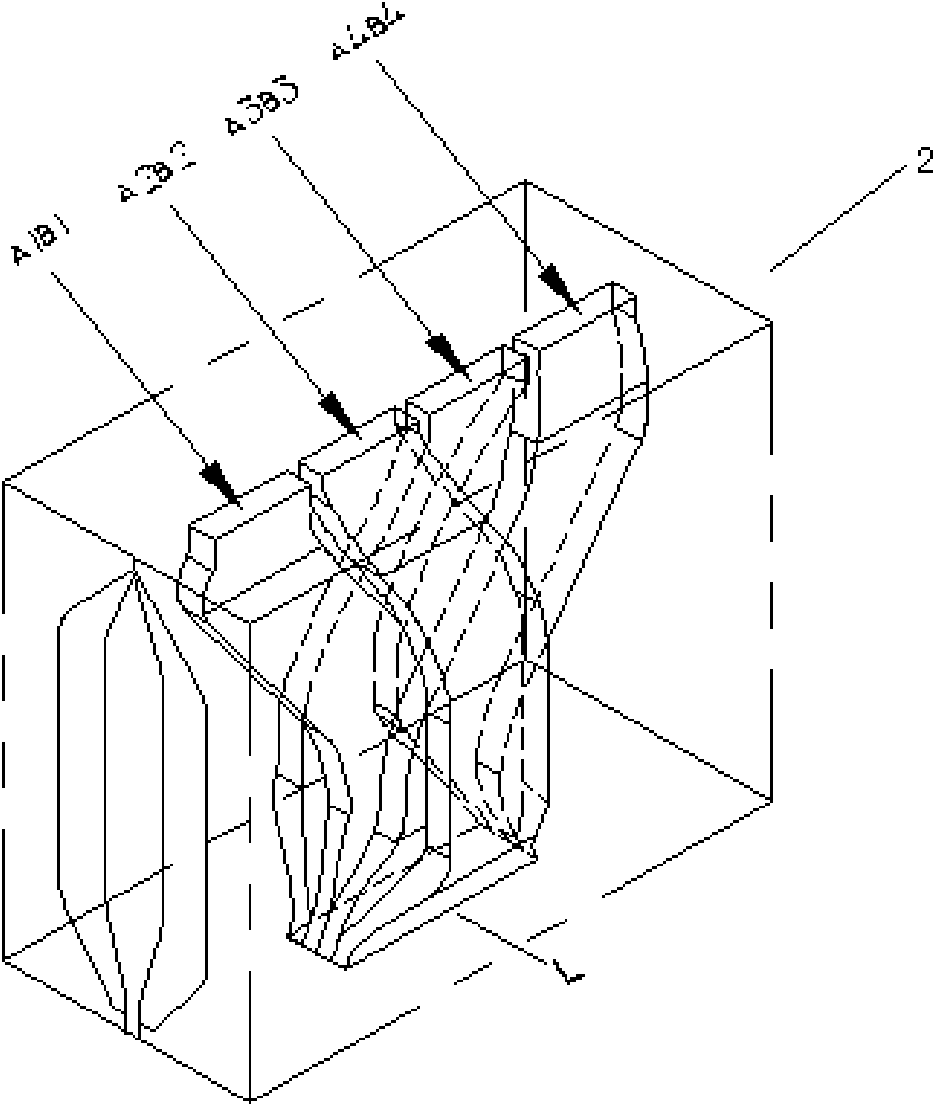

[0024] Such as figure 1 As shown, the microstructure multilayer composite distributor includes a microlayer distributor 1 and a composite multiplier 2, figure 1 Shown in is the single-layer structural plate G1 of the microlayer distributor, in which there are 4 flow layer ports C1, C2, C3, and C4 on the structure plate G1, and there are intervals between the 4 flow layer ports to form 4 independent The flow layer, the feed melt is injected from the main feed channel A, B of the structural plate G1, and enters the flow layer through the co-extrusion structure A30, B30 into the flow layer channel C1, C2, C3, C4 to form a stack, such as figure 2 As shown, U10 is the cross-section of the flow layer formed in the single-layer structural plate. At this time, the number of layers is 2 layers, and the flow layers are A1 / B1, A2 / B2, A3 / B3, and A4 / B4. The composite multiplier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com