Reinforced polypropylene resin material for passenger vehicle engine bottom guard plates

A technology of polypropylene resin and bottom guard plate, applied in the direction of deflectors, etc., can solve the problems of unsatisfactory weight reduction, cost reduction, material recyclability, narrow recycling range, and bulky parts, etc., to achieve light weight, The effect of low cost and increased overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

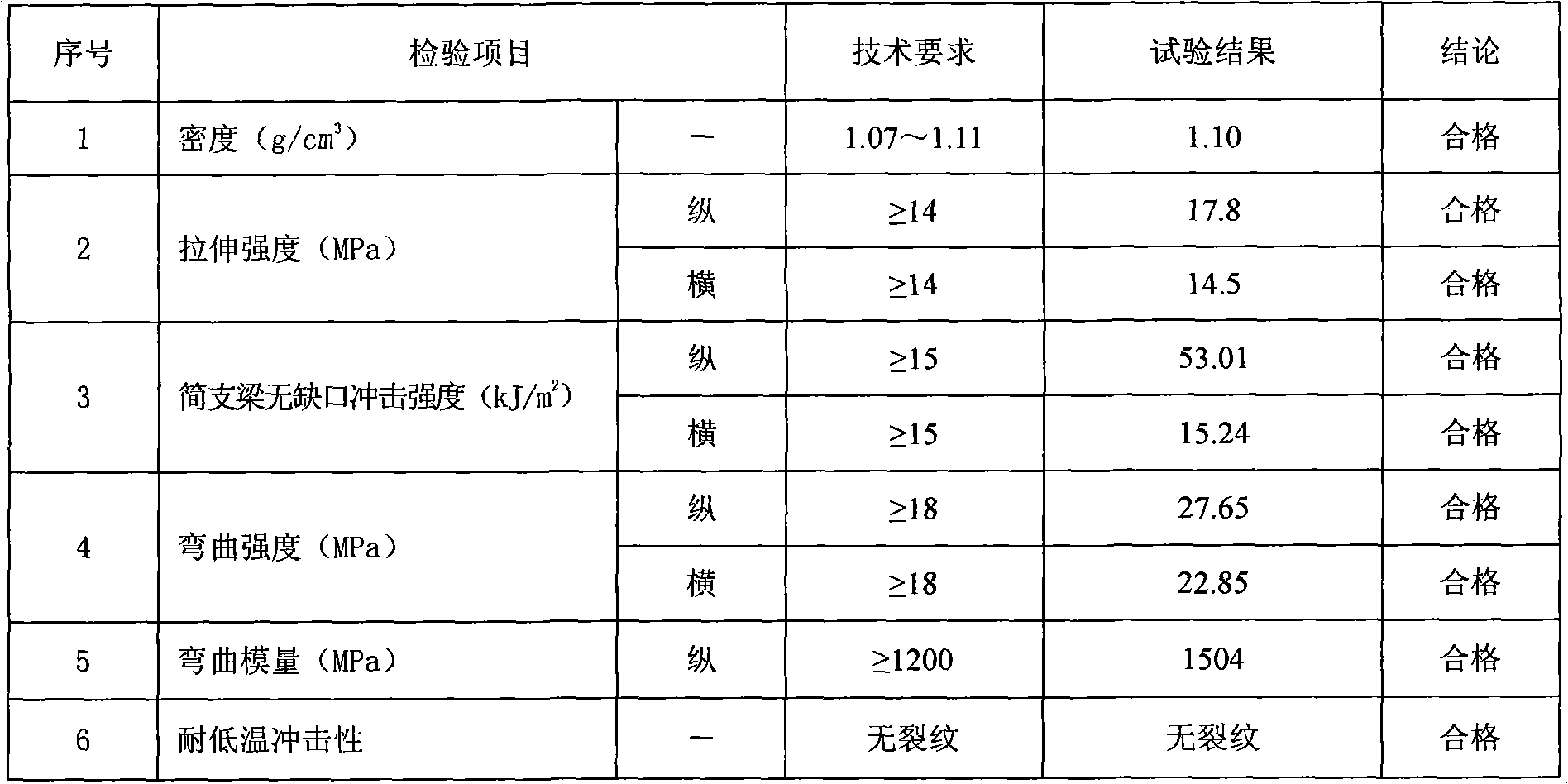

Embodiment 1

[0021] Polypropylene: 68, talcum powder: 25, glass fiber: 7 are weighed and prepared according to parts by weight, and the material sheet is obtained by calendering. The sheet cutting should be cut with a cutting machine, or cut with a hacksaw. The heart wheel should be broken; the size of the sheet should be equal to or smaller than the finished product. When each piece of LFT material enters the mold, the gap between the two materials should be more than two centimeters;

[0022] Then put the weighed sheet into the oven to preheat. It is not advisable to stack more than two layers in the oven. This is to make the material easy to heat through and reduce the heating time. The preheating temperature is 200-220°C and the time is 3-4 minutes. , If the temperature is too high, it will decompose and smoke and affect the performance. If the temperature is too low or the heating is impermeable, it will affect the product pressing effect. After the sheet is preheated, it will be very ...

Embodiment 2

[0025] Polypropylene: 74, talcum powder: 23, glass fiber: 3 are weighed and prepared according to parts by weight, and the material sheet is obtained by calendering. The sheet cutting should be cut with a cutting machine, or cut with a hacksaw. The heart wheel should be broken; the size of the sheet should be equal to or smaller than the finished product. When each piece of LFT material enters the mold, the gap between the two materials should be more than two centimeters;

[0026] Then put the weighed sheet into the oven to preheat. It is not advisable to stack more than two layers in the oven. This is to make the material easy to heat through and reduce the heating time. The preheating temperature is 200-220°C and the time is 3-4 minutes. , If the temperature is too high, it will decompose and smoke and affect the performance. If the temperature is too low or the heating is impermeable, it will affect the product pressing effect. After the sheet is preheated, it will be very ...

Embodiment 3

[0029] Polypropylene: 70, talcum powder: 25, glass fiber: 5 are weighed and prepared according to parts by weight, and the material sheet is obtained by calendering. The sheet cutting should be cut with a cutting machine, or cut with a hacksaw. The heart wheel should be broken; the size of the sheet should be equal to or smaller than the finished product. When each piece of LFT material enters the mold, the gap between the two materials should be more than two centimeters;

[0030] Then put the weighed sheets into the oven to preheat. It is not advisable to stack more than two layers in the oven. This is to make the material easy to heat through and reduce the heating time. The preheating temperature is 200-220°C and the time is 3-4 minutes. , If the temperature is too high, it will decompose and smoke and affect the performance. If the temperature is too low or the heating is impermeable, it will affect the product pressing effect. After the sheet is preheated, it will be very...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com