3m innovative properties co

An antimicrobial film and antimicrobial technology, applied in biocides, animal repellents, plant growth regulators, etc., can solve problems such as increased medical costs, reduced worker productivity, and illness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

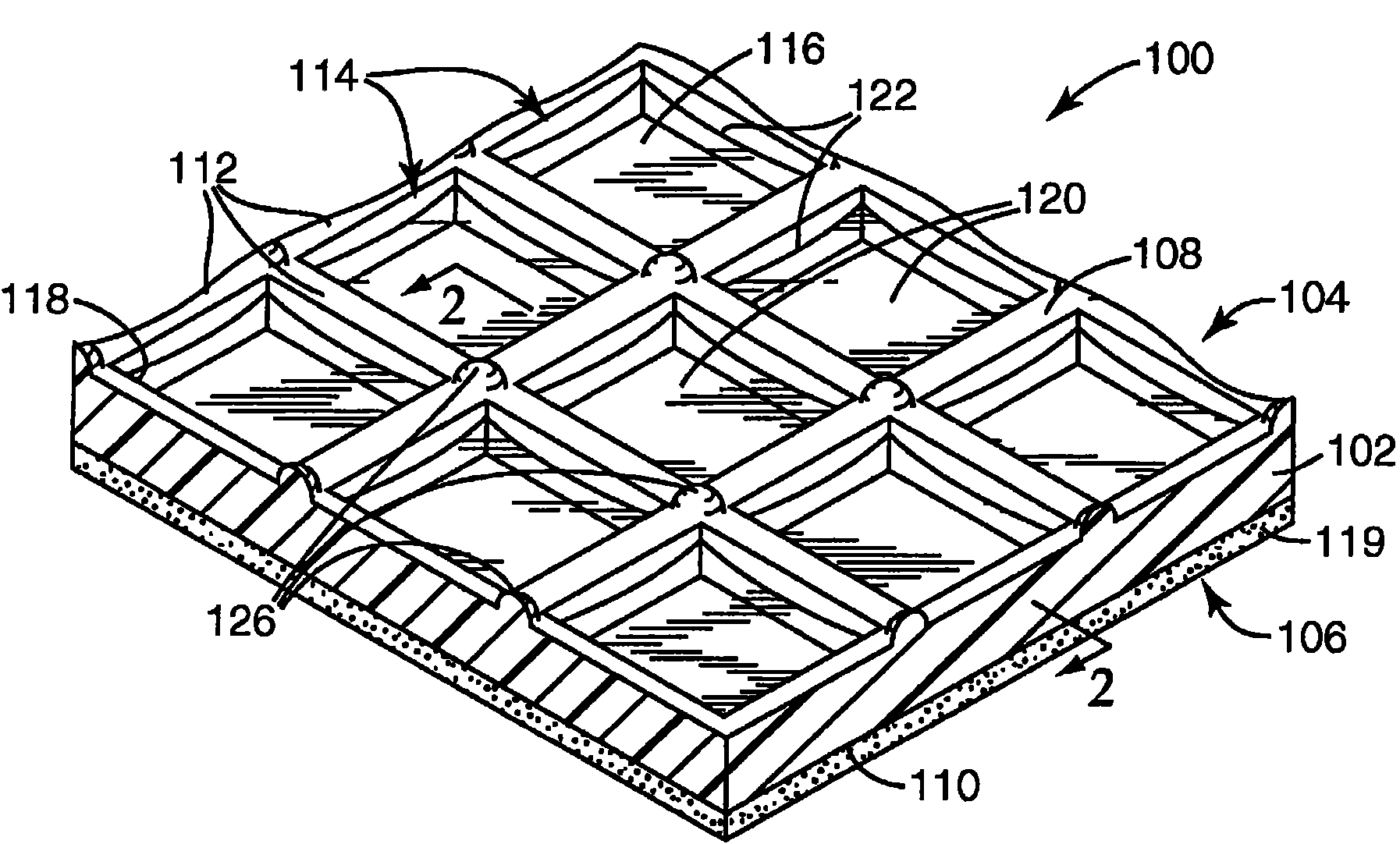

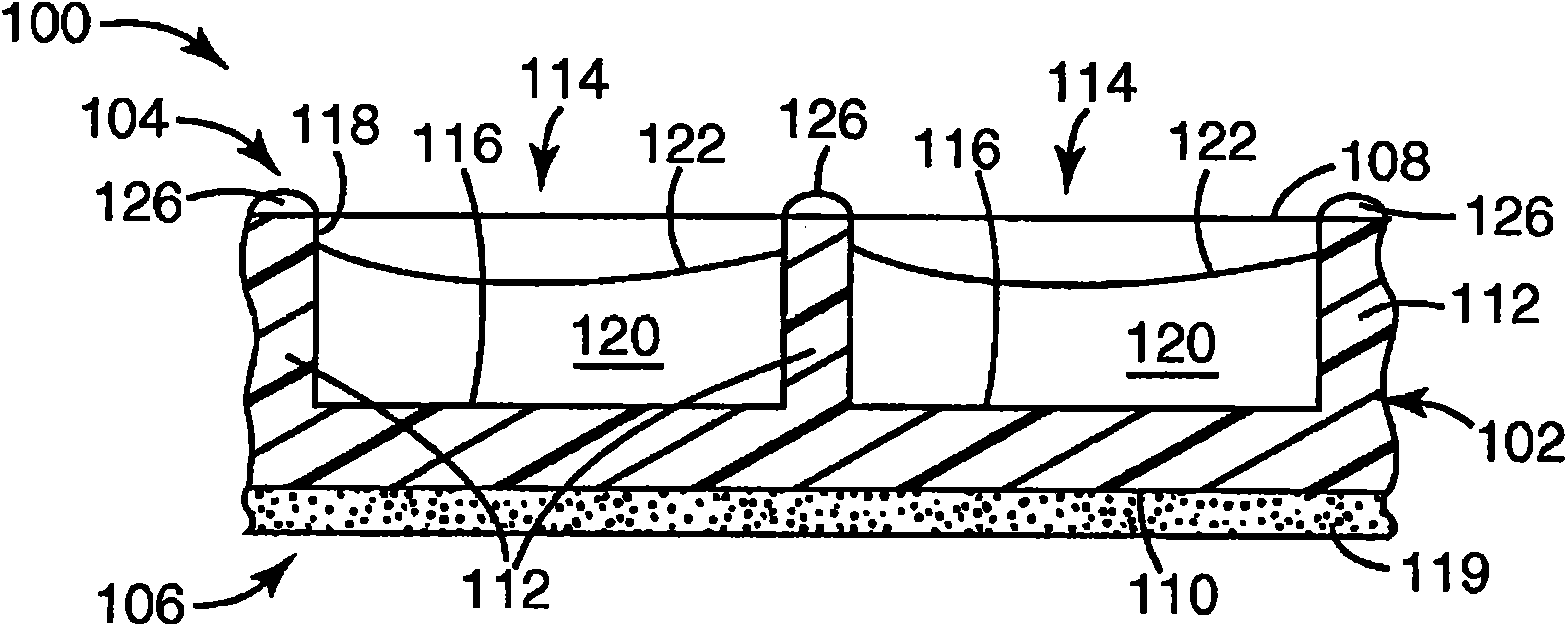

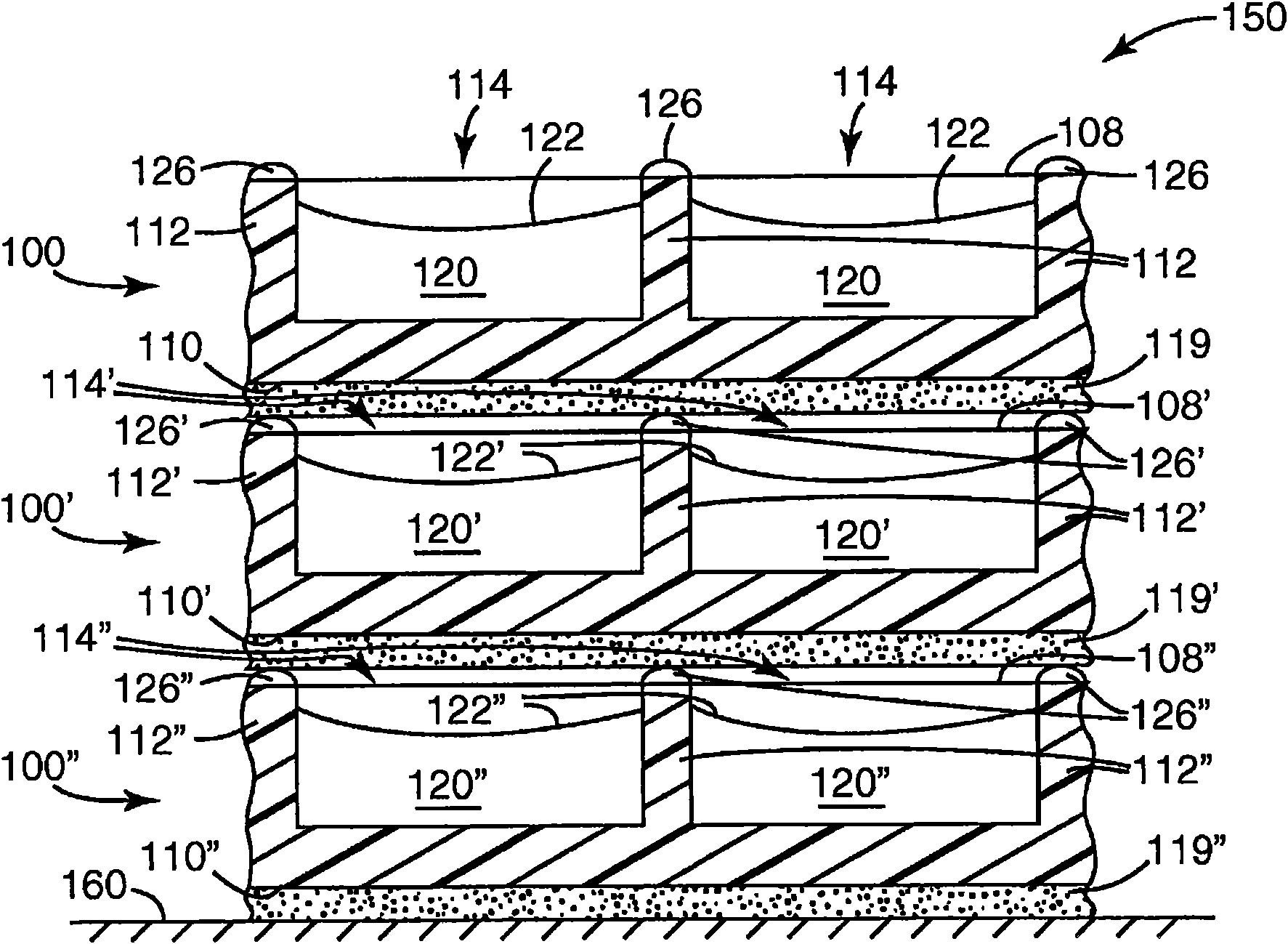

Image

Examples

example 1

[0187] An antimicrobial composition containing 20 parts of Permuthane, 30 parts of toluene, 2 parts of N-75 isocyanate, and 0.2 parts of AgION was prepared by mixing all ingredients in a small jar. The antimicrobial composition is applied to the microstructured side of the microstructured membrane using a smooth Teflon-coated glass rod such that the coating is pressed into the primary well of the membrane below the first major surface of the membrane so that when the solvent Upon evaporation, the binder / antimicrobial composition is confined to primary wells on the microstructured surface of the film, forming a microstructured antimicrobial film beneath the first major surface of the film.

[0188] The antimicrobial composition-coated surface of the microstructured antimicrobial film was brought into contact with the adhesive surface of the GLAM film, and the construction was rolled twice with a 1300-gram roller.

[0189] The construction was aged for 54 days at 73.4°F (23°C) a...

example 2

[0194] Using a smooth Teflon-coated glass rod, a mixture containing 20% by weight of Lauricidin, 10% by weight of salicylic acid, 10% by weight of succinate sulfonic acid surfactant (50% solution) and 60% by weight of A fatty acid monoester based antimicrobial material of isopropanol is brushed onto the microstructured side of the microstructured film, thereby pressing the antimicrobial material into the primary wells of the microstructured film to form the microstructured antimicrobial film. As a control, the same antimicrobial material was coated onto the smooth side (ie, second side) of the microstructured membrane using a #24 Meier rod, providing a dry coating approximately 8 microns thick. The coating was allowed to dry in an oven at 50°C for 5 minutes. The zone of inhibition test and microbial reduction test were performed on two samples. The results are shown in Tables 2 and 3 below.

[0195] Table 2: Circle of Inhibition Results

[0196]

[0197] Table 3: M...

example 3

[0200] An acrylic binder based antimicrobial material was prepared by mixing 9 parts Neocryl XK-90 and 1 part crosslinker (Part B). Component B was prepared by mixing 76 parts ethanol, 22.8 parts CX-100 and 1.2 parts Surfynol 104PA. All ingredients were mixed in a beaker under high shear for 20 minutes. Add 0.5 parts of AgION to the mixture. The resulting composition was coated onto the microstructured side of the microstructured membrane using a smooth Teflon-coated glass rod, thereby pressing the coating into the primary wells of the microstructured membrane to form a microstructured antimicrobial membrane. As a control, the same acrylic antimicrobial material was coated onto the smooth side (ie, second side) of the microstructured film using a #24 Meier rod, resulting in a dry coating approximately 10 microns thick. The coated duplicate samples were placed in an oven, dried at 55°C for 10 minutes, and tested using the microbial reduction assay. The results of microbial r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com