Solenoid valve with multiple-part armature without armature guide

A solenoid valve and armature technology, applied to engine components, machines/engines, fuel injection pumps, etc., can solve problems such as narrow tolerances, increased tolerance chains, laborious assembly, etc., and achieve the effect of small rebound tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

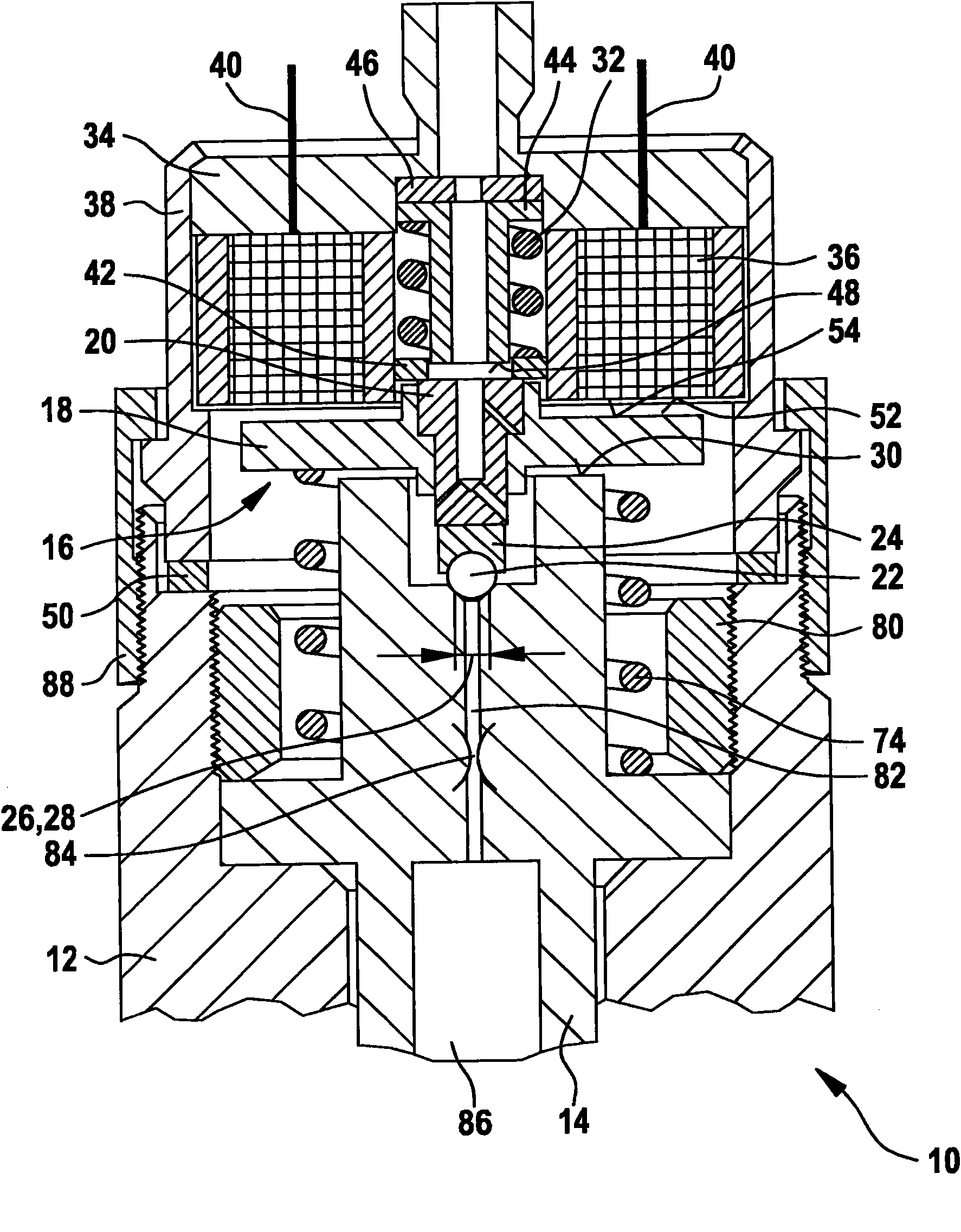

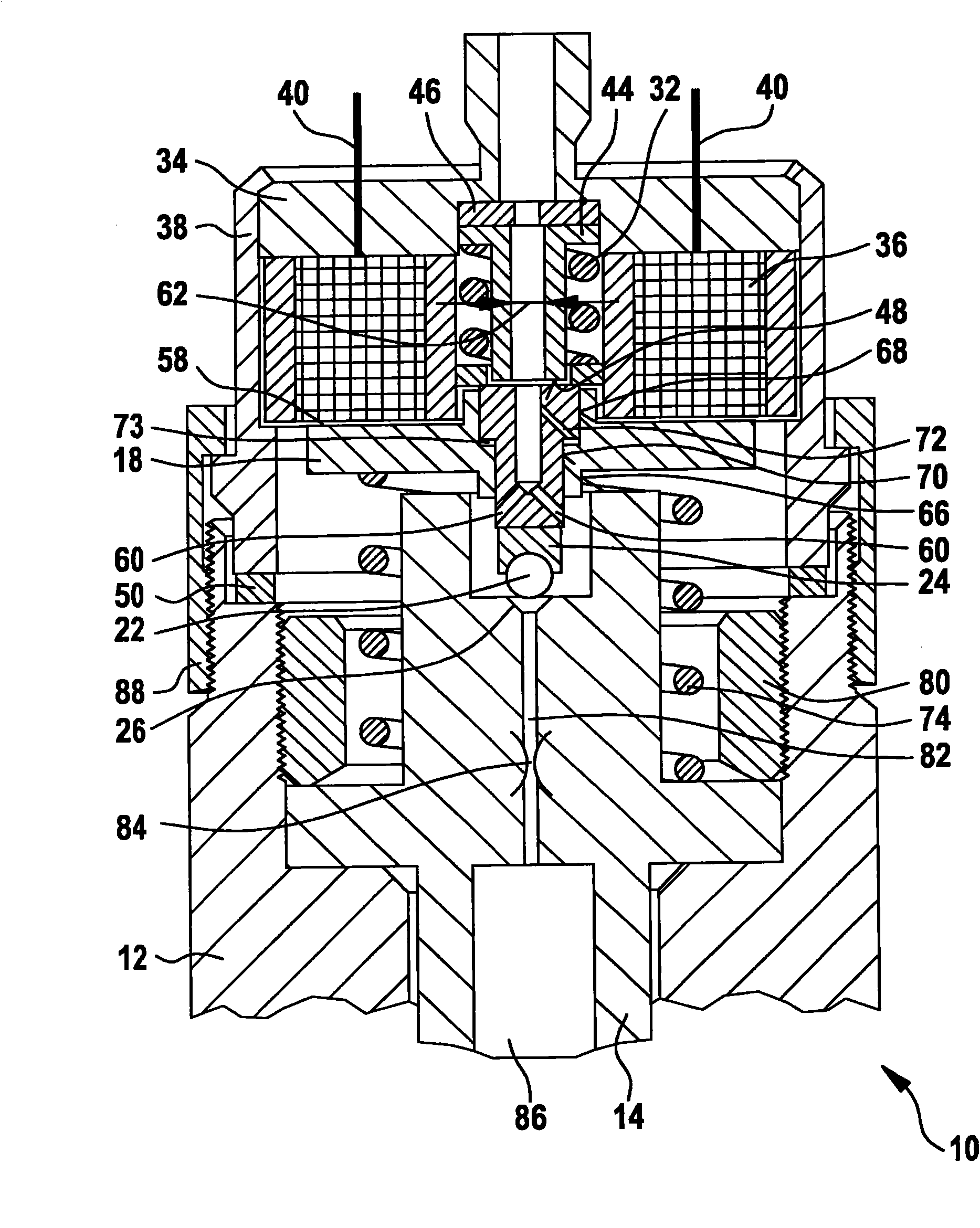

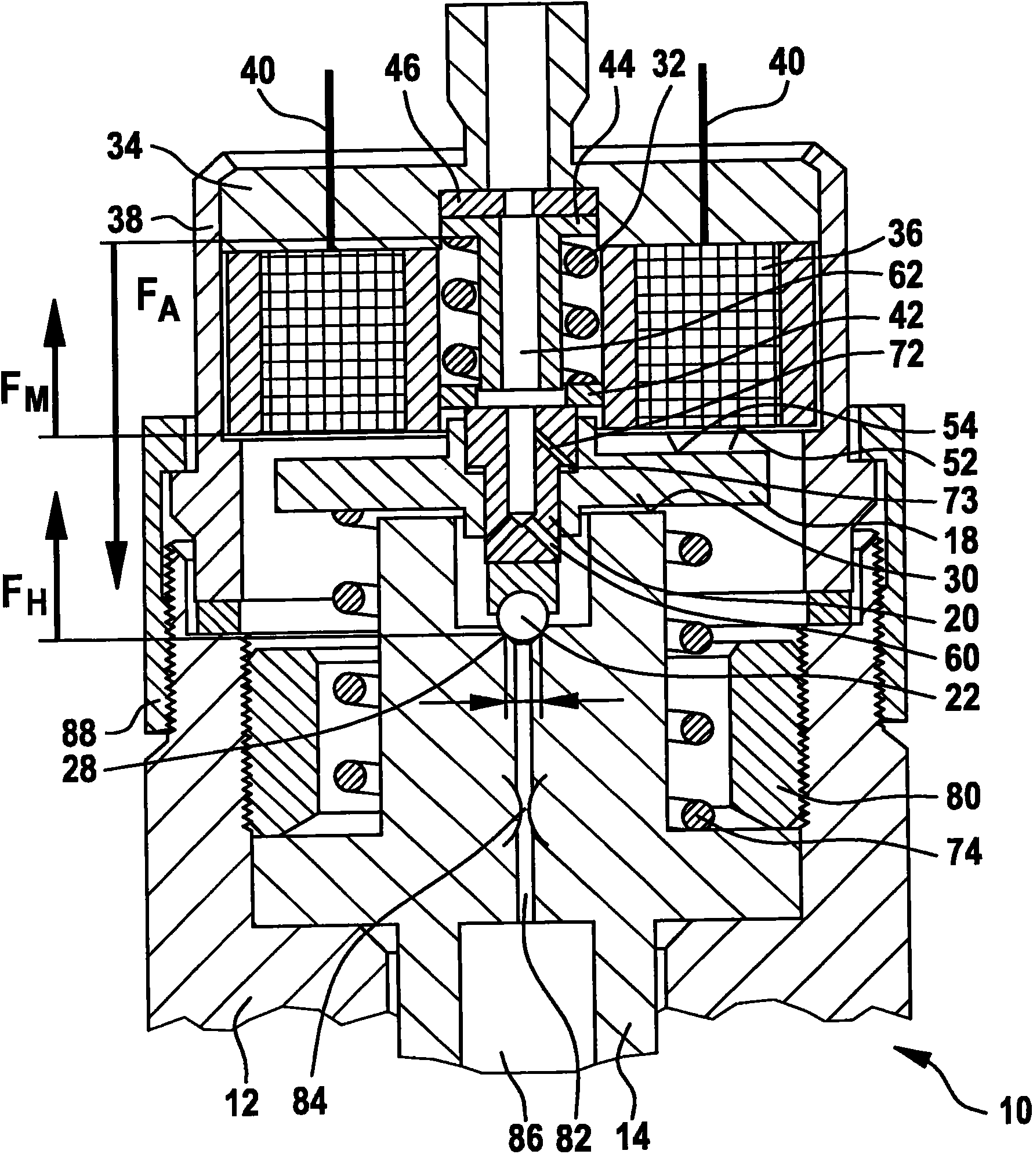

[0014] figure 1 The solenoid valve proposed according to the invention for operating a fuel injector is shown in a rest phase, ie when the solenoid coil is not energized.

[0015] Such as figure 1 As shown, the fuel injector 10 includes a solenoid valve which essentially includes a multi-part armature 16 with an armature plate 18 and an armature pin 20 and a solenoid coil 36 received in a solenoid sleeve 38 . The solenoid coil 36 of the solenoid valve is energized via the depicted electrical contact 40 .

[0016] The fuel injector 10 includes an injector body 12 in which a valve block 14 is received. Inside the valve block 14 there is a control chamber 86 which is passed through the figure 1 The meter-in structure, not shown, is loaded with fuel at system pressure. The pressure level inside the control chamber 86 of the valve block 14 corresponds to the system pressure p or the control pressure p generated by the high-pressure delivery unit (such as a high-pressure deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com