Spindle transporting trolley

A technology for transporting ingots and trolleys, which is applied in the field of ingot transporting trolleys, which can solve problems such as hindering the manipulator track, low work efficiency, and affecting forging quality, and achieve the effect of simple control, improved work efficiency, and easy control automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but those skilled in the art should understand that this is not a limitation.

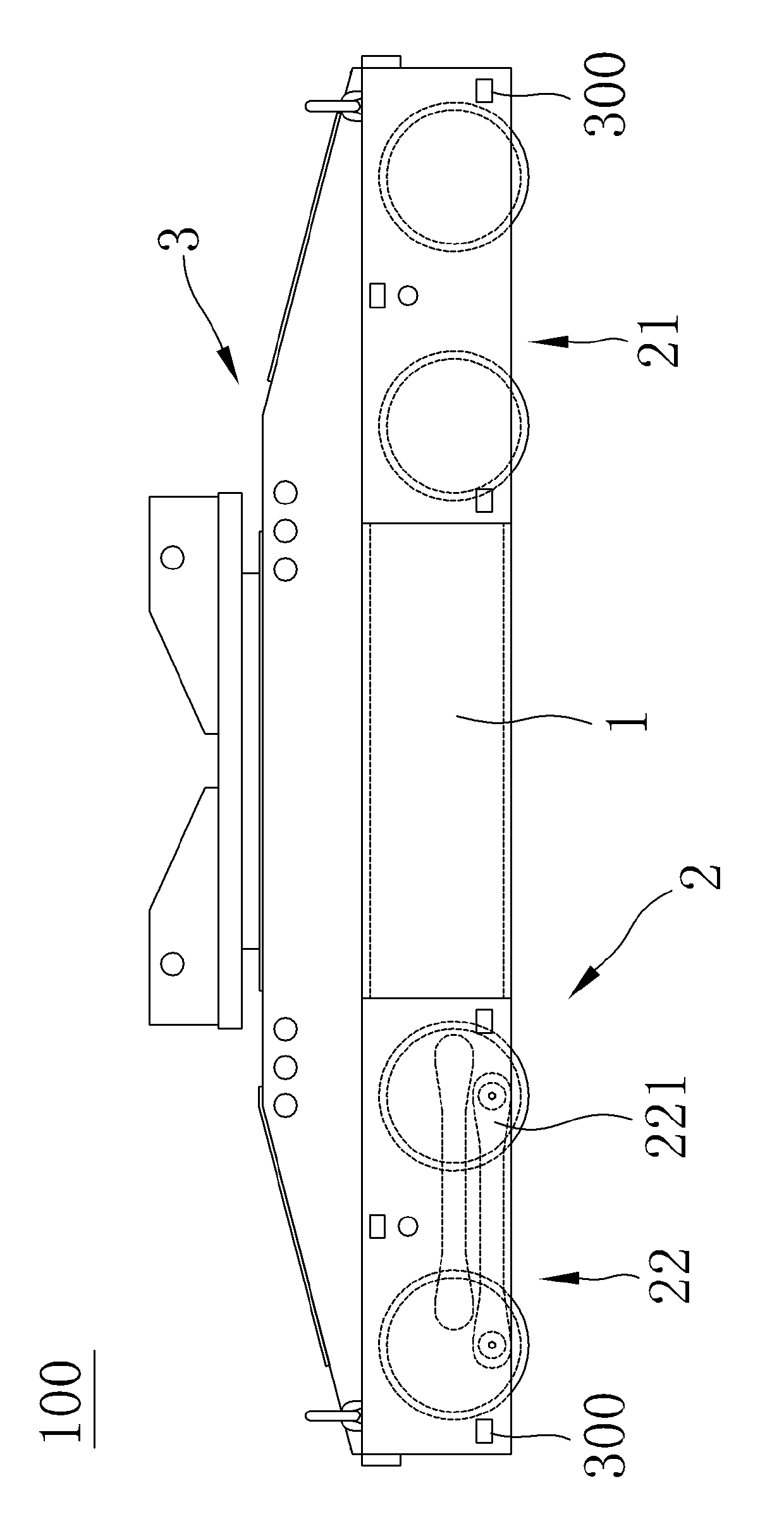

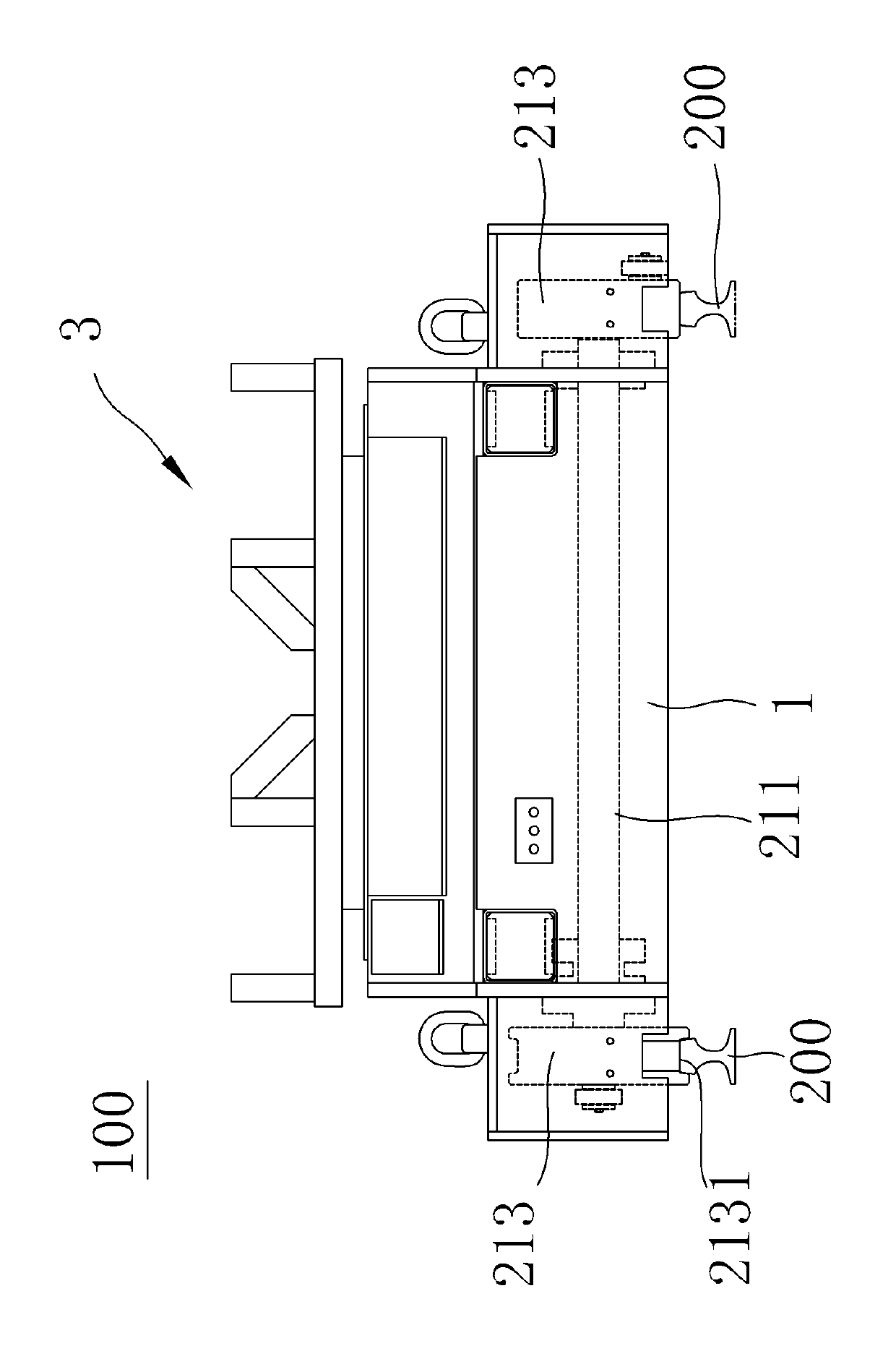

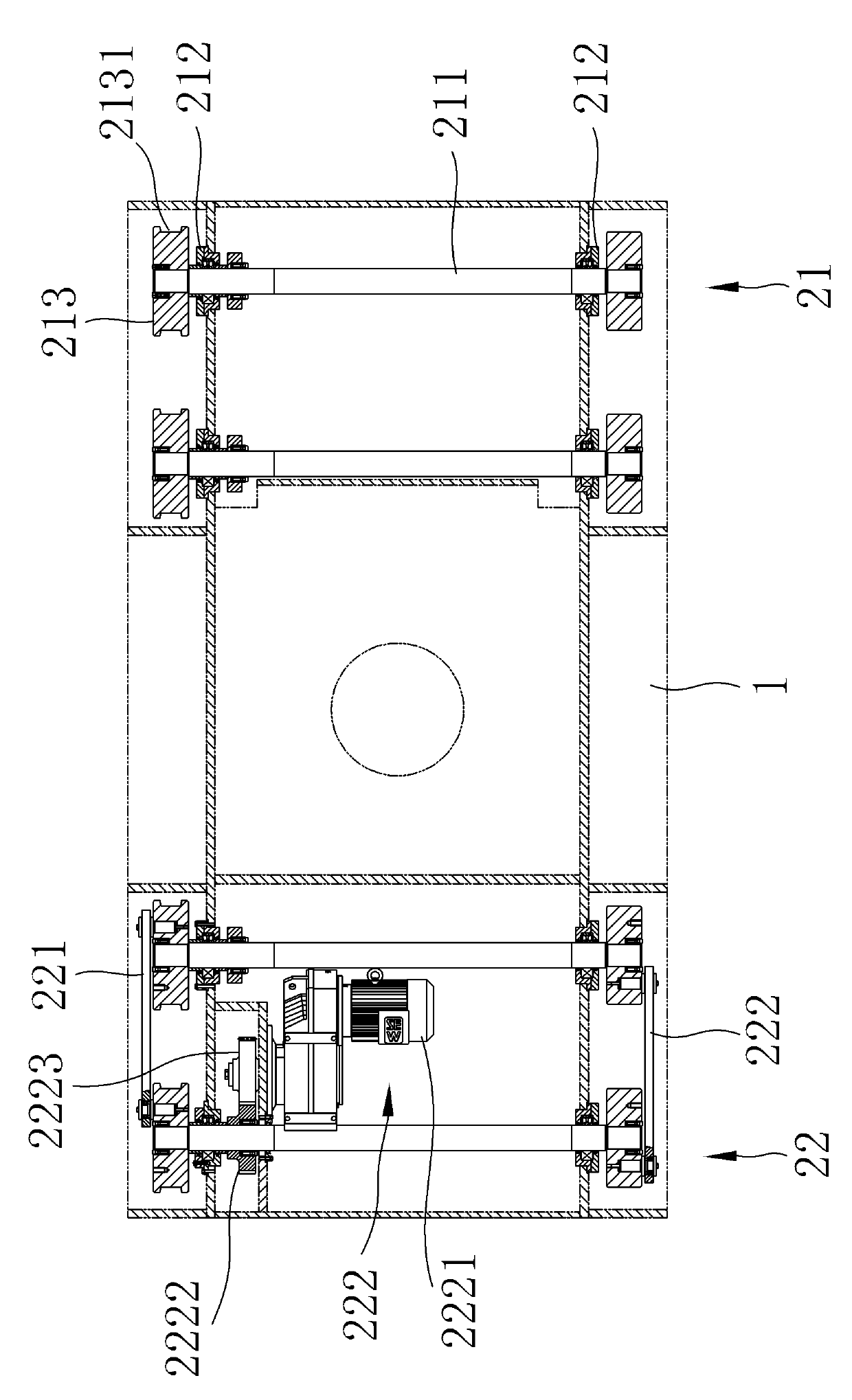

[0067] Please refer to figure 1 and figure 2 ,in figure 1 It is a schematic diagram of the overall front view of the ingot transport trolley of the present invention, figure 2 It is a schematic diagram of the overall side view of the ingot transporting trolley of the present invention. As shown in the figure, the ingot transporting trolley 100 of the present invention mainly includes: a car body 1, a traveling mechanism 2 and a rotating mechanism 3, wherein the traveling mechanism 2 is arranged at the bottom of the car body 1, and its It is mainly used to drive the ingot conveying trolley 100 to make it move; the rotating mechanism 3 is arranged on the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com