Automobile crane and energy-saving control method and energy-saving control system thereof

An energy-saving control system, a technology for truck cranes, applied in cranes, engine control, mechanical equipment, etc., can solve problems such as energy waste, difficult engine power matching and balance, and inability to guarantee crane work, etc., to achieve energy-saving goals and ensure operation requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

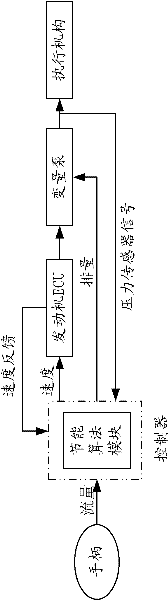

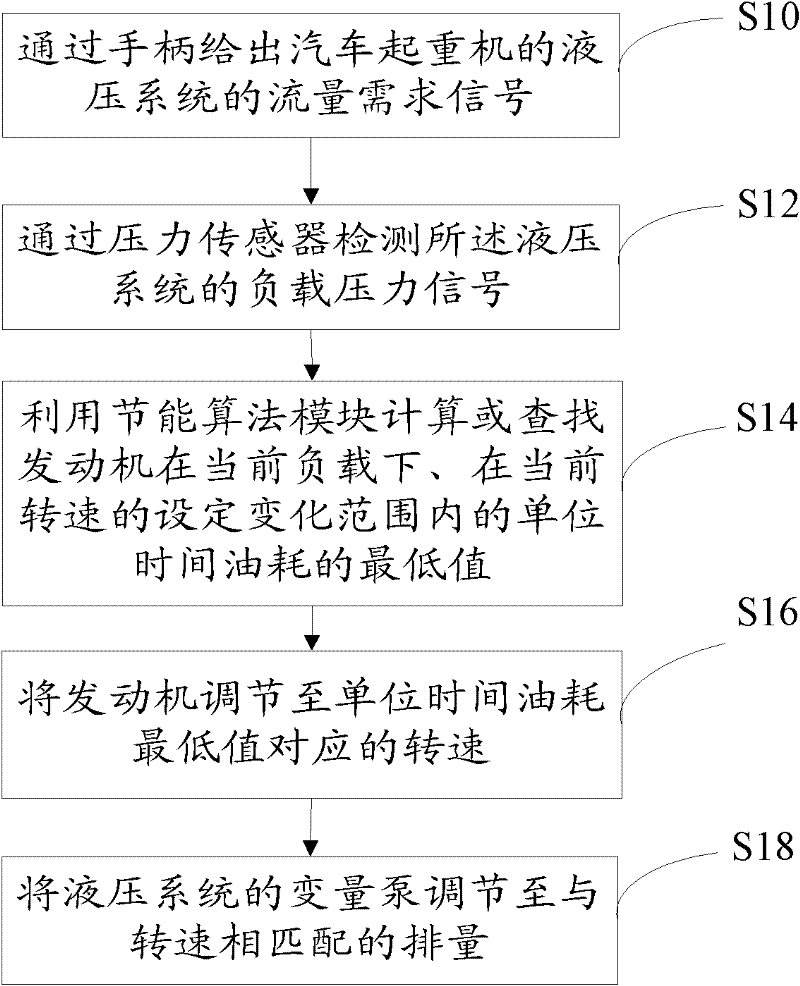

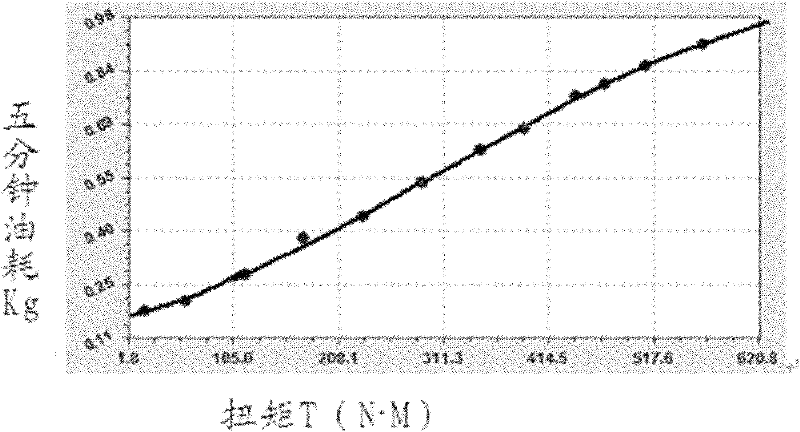

[0024] figure 1 It shows the functional block diagram of the energy-saving control system of the truck crane according to the present invention. Such as figure 1 As shown, the flow demand signal is given by the handle, and the flow demand signal is sent to the controller. At the same time, the controller obtains the load under the load according to the flow demand signal and the load pressure signal detected by the pressure sensor by the energy-saving algorithm module combined with the principle of power matching. The optimal speed of the engine and the displacement of the variable pump matching the optimal speed.

[0025] The speed of the mechanical action of the crane is determined by the flow rate of the hydraulic system. The operator manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com