Intelligent control system for four-column hydraulic machine tool

An intelligent control system and control system technology, applied in presses, manufacturing tools, etc., can solve the problems of structural redundancy, long design cycle, lack of result verification, etc., to improve control accuracy, realize automatic fault diagnosis function, and reduce complexity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

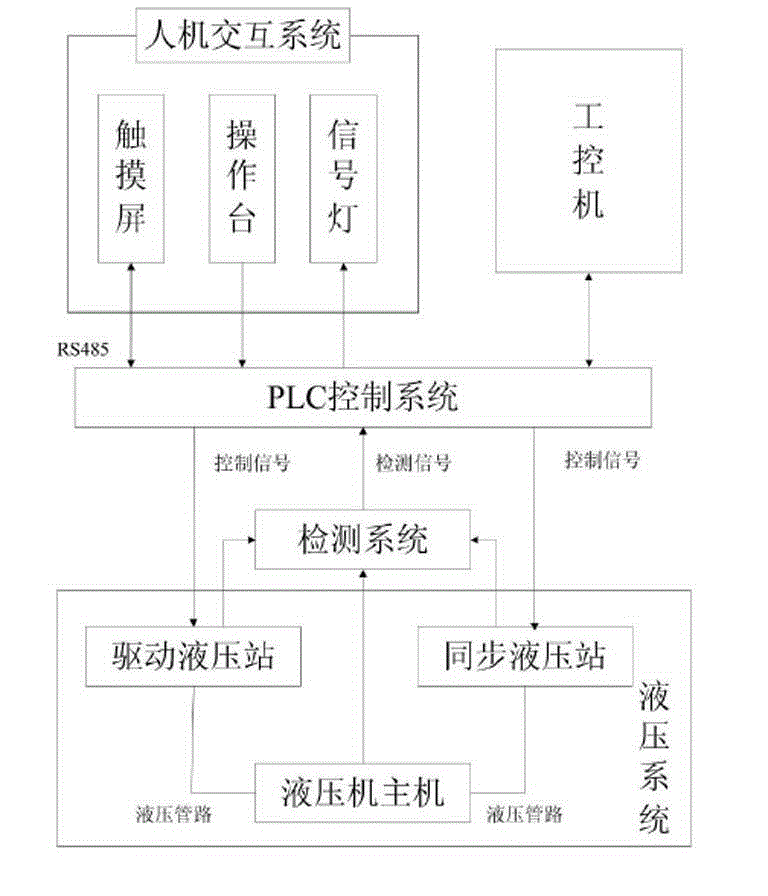

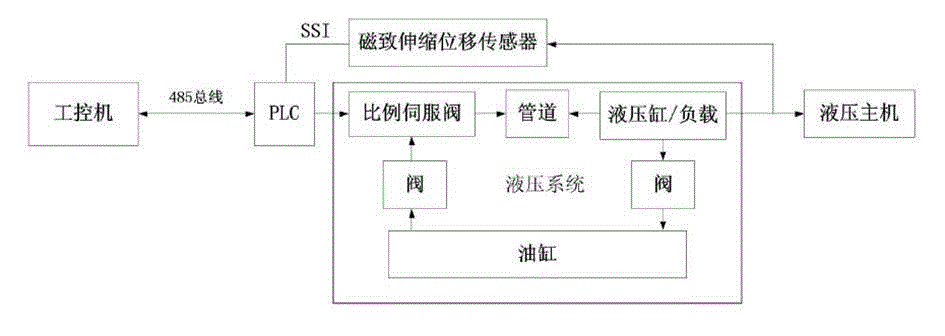

[0011] As shown in the figure: an intelligent control system for a four-column hydraulic machine tool, which consists of an industrial computer, a human-computer interaction system, a PLC control system, a hydraulic system, and a data acquisition and detection system. The input end of the data acquisition and detection system receives the output signal of the hydraulic system, the output port of the data acquisition and detection system is connected to the input end of the PLC control system, and the output end of the PLC control system is bidirectionally connected with the industrial computer and the human-computer interaction system through the 485 bus communication.

[0012] The above-mentioned human-computer interaction system is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com