Optical glass, optical element and preformed body

A technology for optical glass and optical components, applied in the field of optical components, preforms, and optical glass, can solve the problems of difficult glass processing, easy damage to glass, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

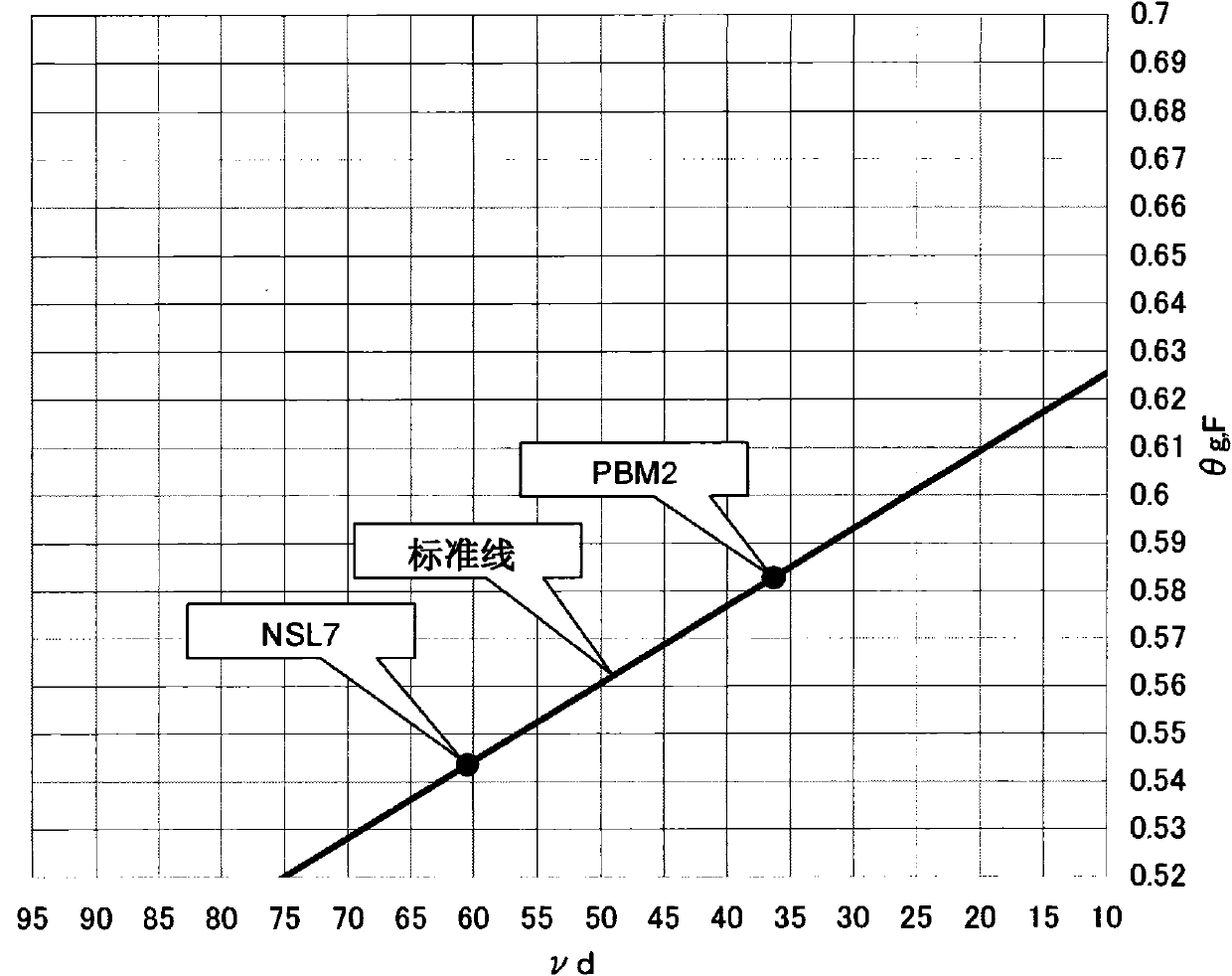

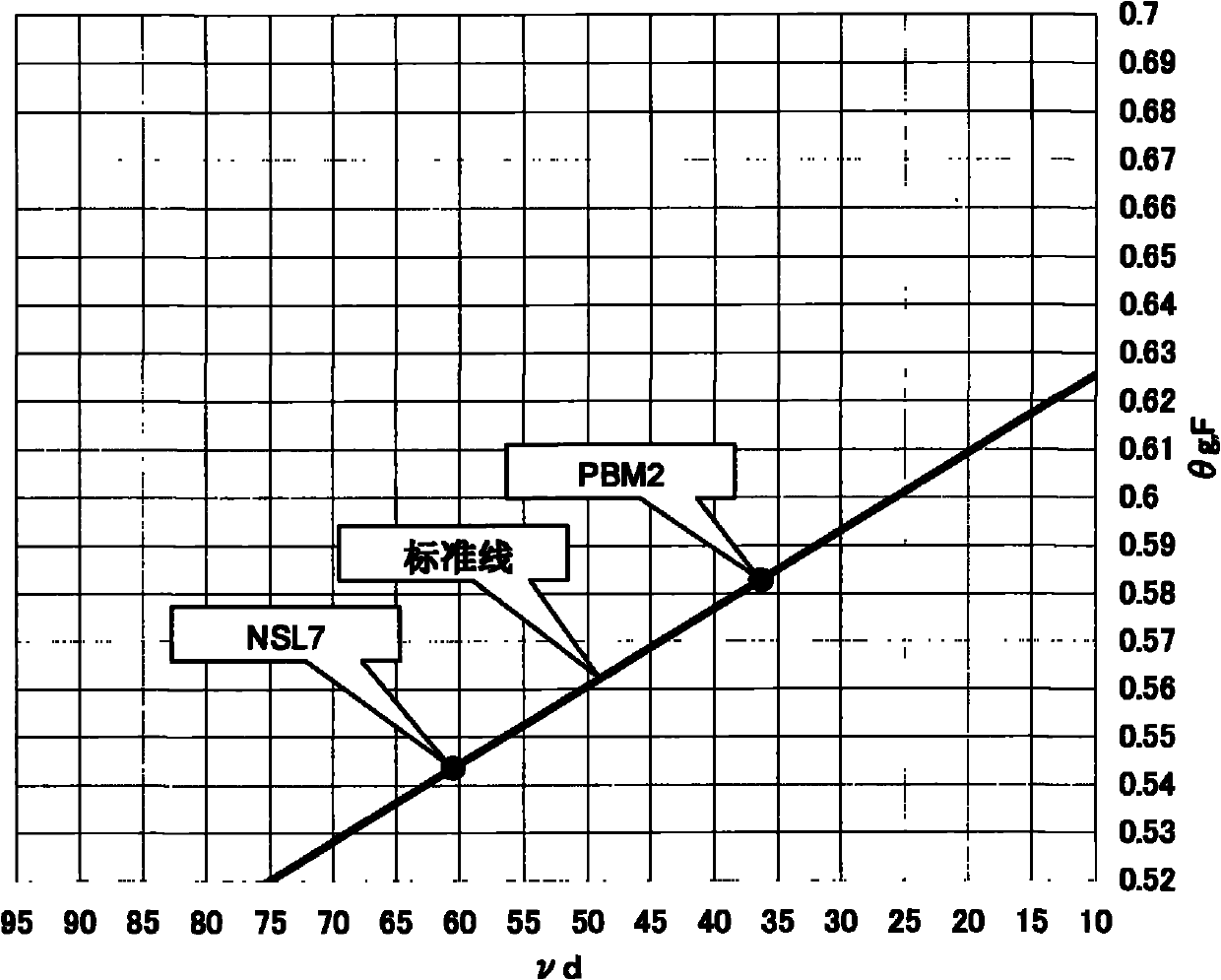

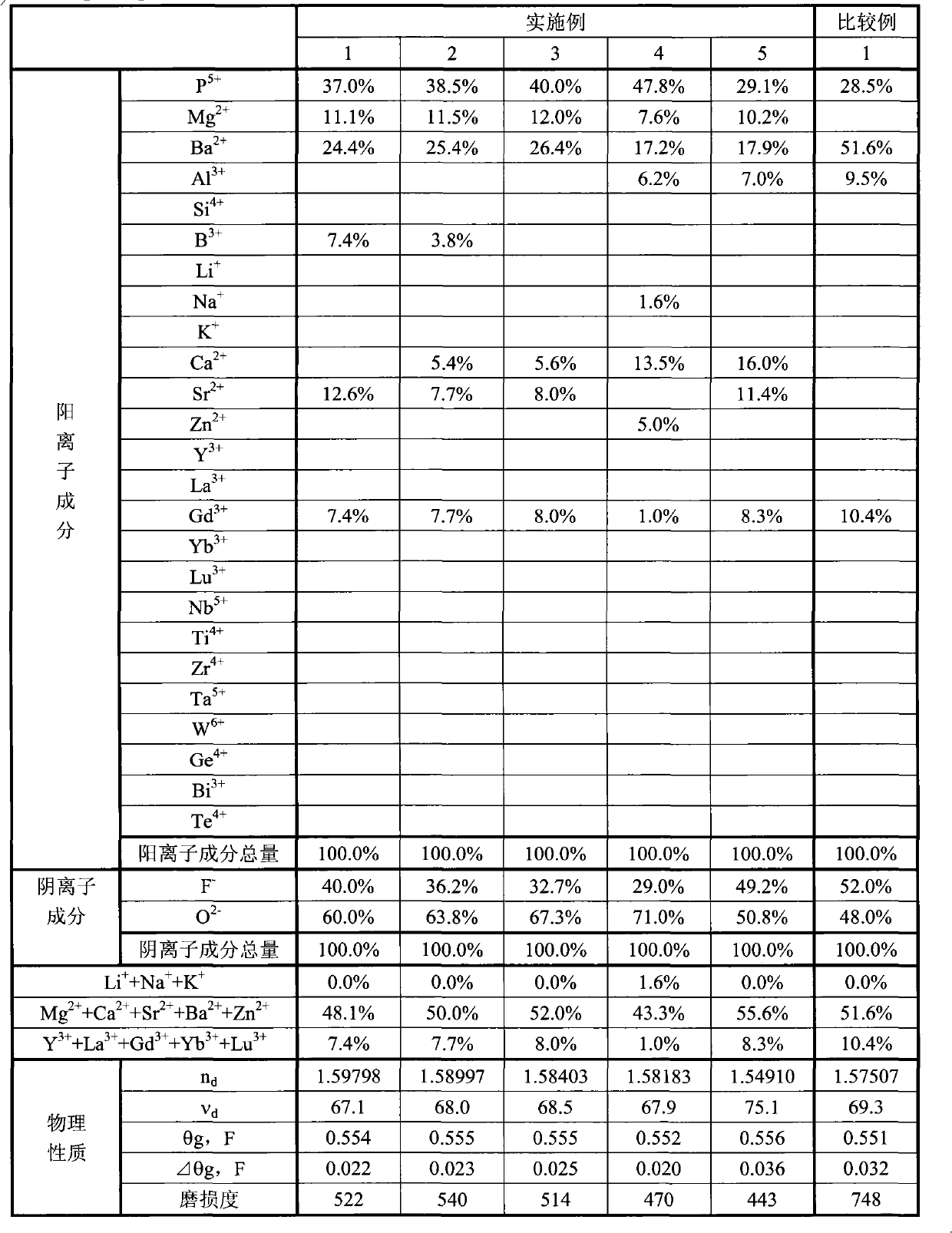

[0104] The composition and refractive index (n d ), Abbe number (ν d ), partial dispersion ratio (θg, F), anomalous dispersion (Δθg, F) and wear degree are shown in Table 1. It should be noted that the following examples are for illustrative purposes only, and the present invention is not limited to these examples.

[0105] For the optical glass of the examples (No.1-No.5) of the present invention and the glass of the comparative example (No.1), oxides, carbonates, nitrates, fluorides, and metaphosphoric acid compounds corresponding to each component are selected. The high-purity raw materials used in common fluorophosphate glass are weighed and mixed uniformly according to the composition ratios of the examples and comparative examples shown in Table 1 as the raw materials of each component. Then put the mixture of raw materials into a platinum crucible, and according to the melting difficulty of the glass composition, melt it in an electric furnace at a temperature range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com